Chamber and deep hole blasting method of gob

A technology of deep hole blasting and goaf, applied in blasting and other directions, can solve the problem of high processing cost, and achieve the effects of simple operation, high mining intensity and low dilution rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

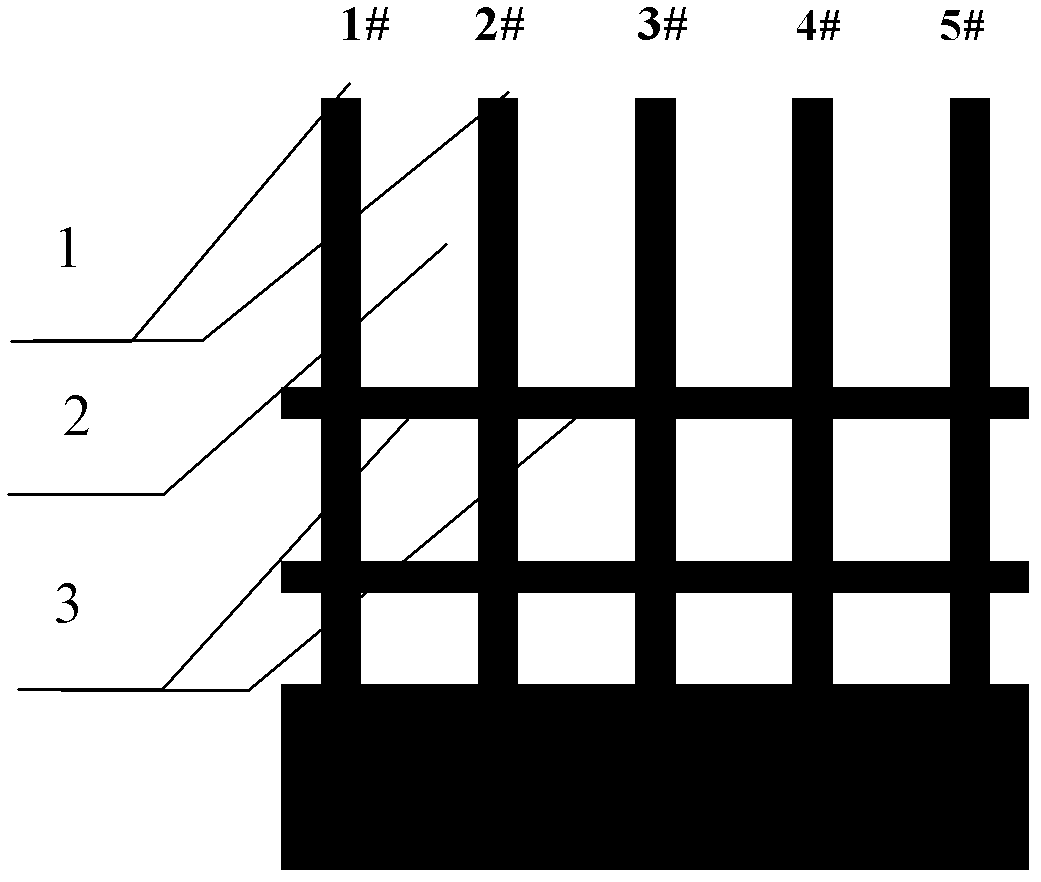

[0026] like figure 1 As shown, the mining of the ore body forms a goaf 2 and a spacer 1. For the convenience of description, the spacer 1 is sequentially numbered as 1#, 2#, 3#, 4#, and 5#. The inter-column 1 is handed over to the top column or the top and bottom columns 3, and there is a goaf mine room 2 between them.

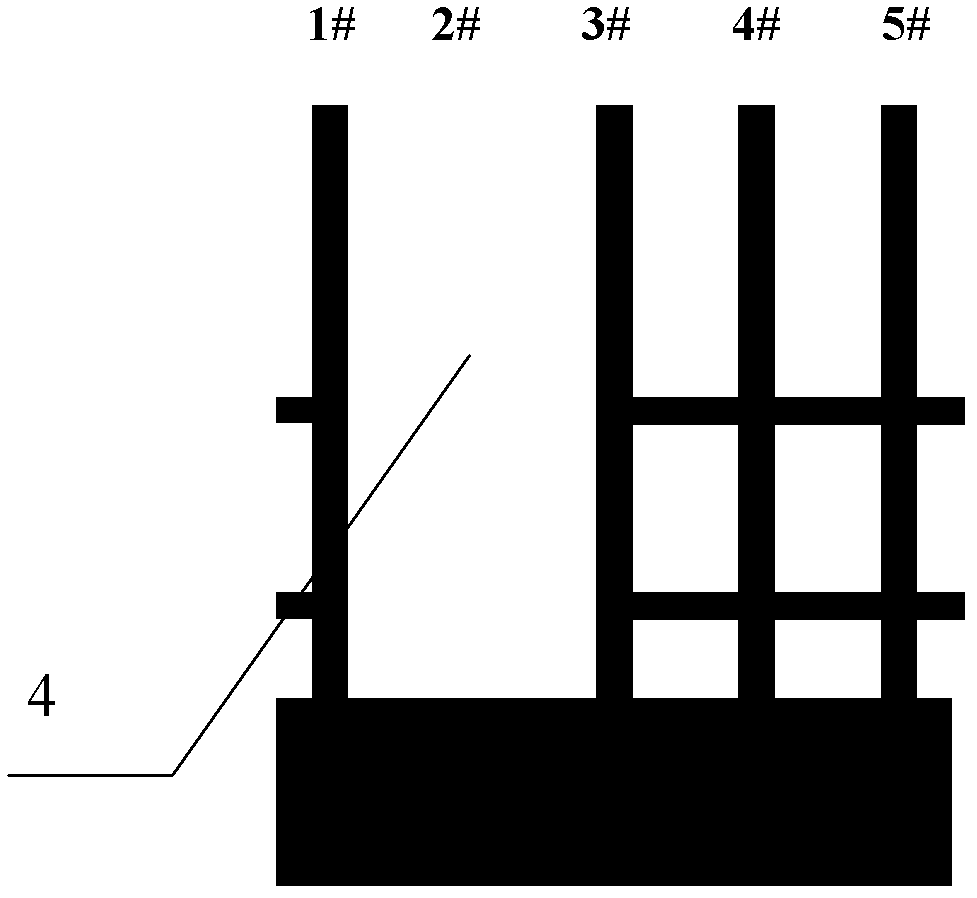

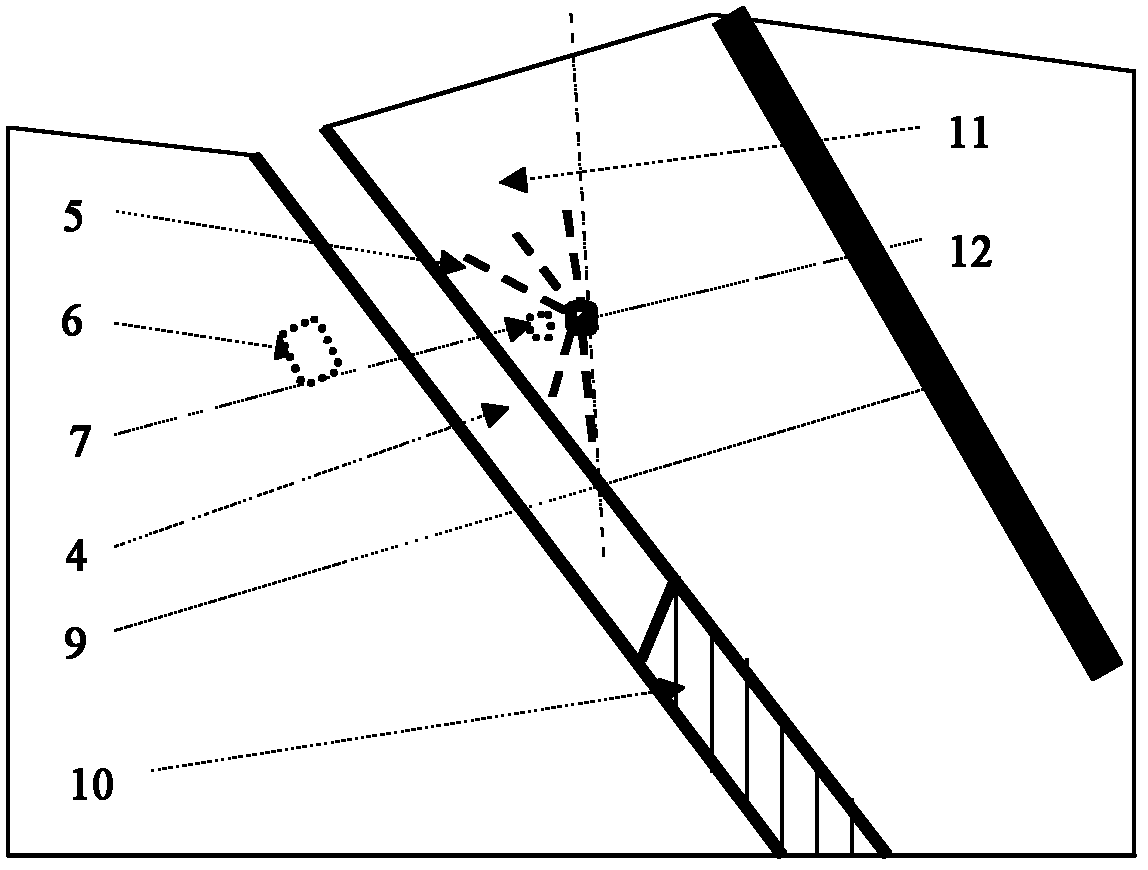

[0027] like figure 2 As shown, interval 1#, 3# intercolumn 1 is extracted from the first middle section to the third middle section from top to bottom 2# intercolumn 1 and the top or top and bottom columns 3 on both sides, and at the same time in the first middle section or the second middle section floor In the corresponding surrounding rock of the upper wall, the horizontal construction roadway 12 for deep hole rock drilling is constructed along the direction of the goaf 4, and then the deep hole 5 rock drilling is implem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com