An Improved Mining Method for Segmented Mine

A mining method and mine house technology, which are applied in the field of improved segmented mine house mining, can solve the problems of large ore loss and dilution, large horizontal span of the mine house, and large exposure area of the stope, so as to achieve low ore loss and dilution, The effect of improving labor productivity and expanding the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

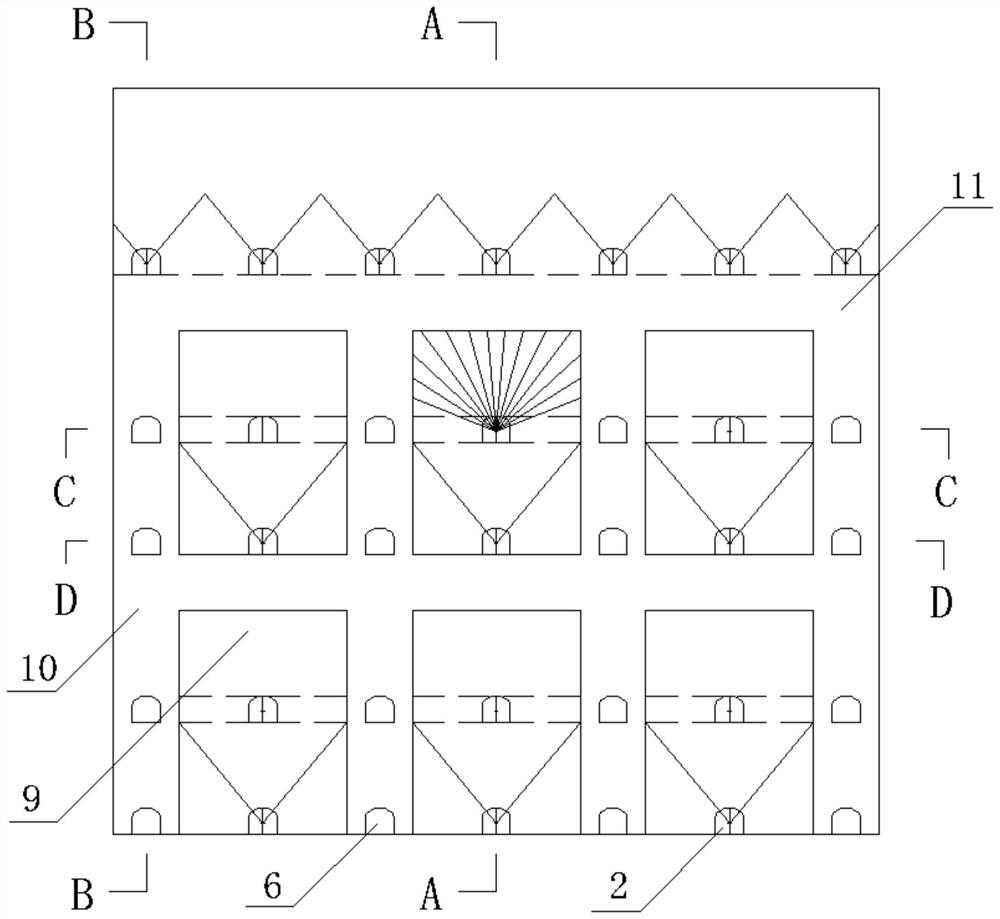

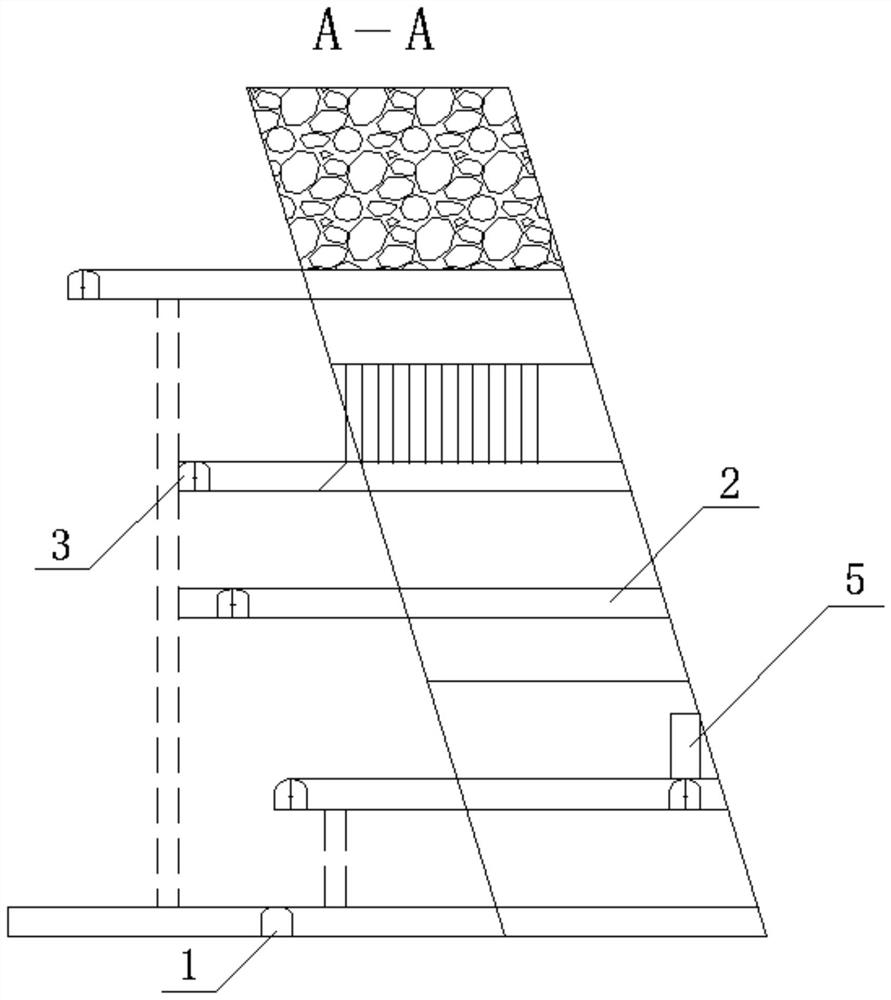

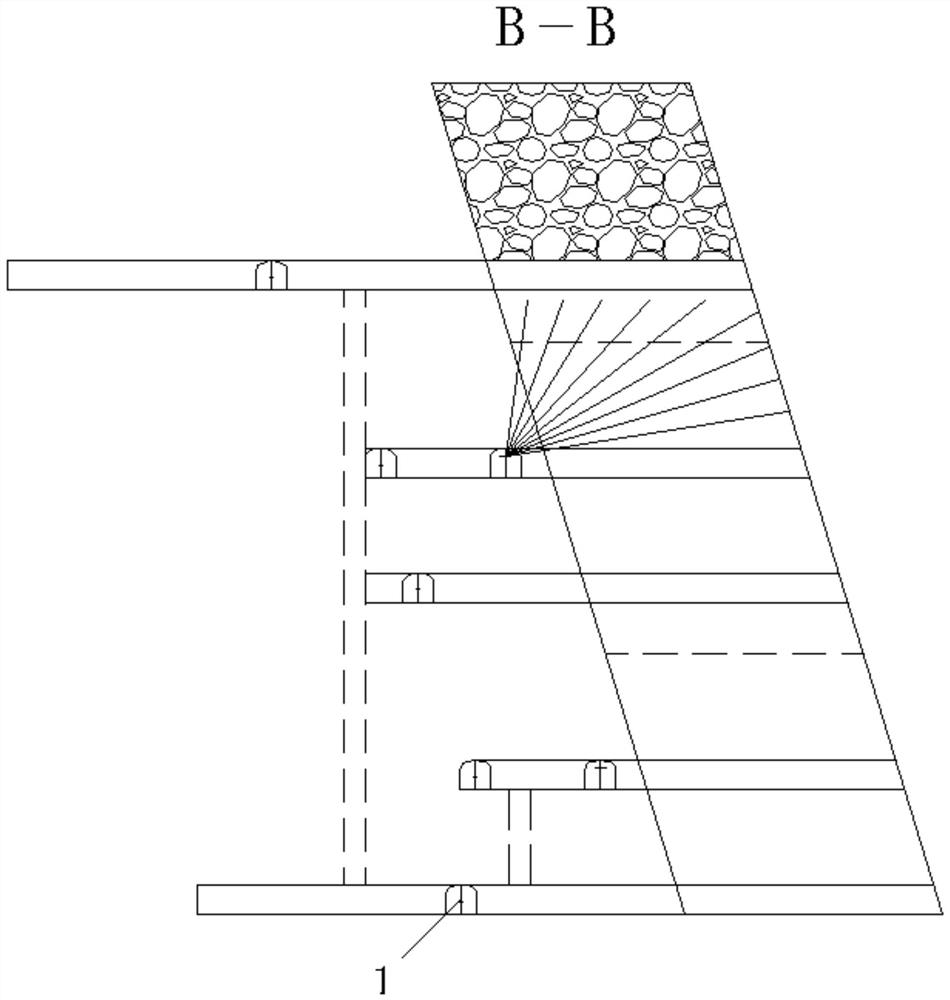

[0026] Example 1: Figure 1 to Figure 5 The ore body structure of an iron mine in central Yunnan has an average horizontal thickness of 25 meters, an average dip angle of 60°, and a stage height of 60 meters. In the figure, 1 is the transportation roadway at the footwall stage, 2 is the ore-collecting trench, and 3 is the segmented roadway. 4 is the chute, 5 is the cutting patio, 6 is the mining roadway, 7 is the ore loading roadway, 8 is the rock drilling roadway, 9 is the mine room, 10 is the inter-column, 11 is the top column, and 12 is the inter-column rock drilling chamber , 13 is the intercolumn recovery deep hole, and 14 is the ore body boundary. The iron ore body is a sharply inclined thick ore body with moderately stable ore rocks. The segmented mine room method is adopted, and the mine room is arranged vertically to the ore body.

[0027] An improved mining method for segmented mine houses, including: segmental rock drilling, segmented ore extraction, segmented top ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com