A method for ore dropping of vertical deep hole spherical charge

A technology of vertical deep hole and medicine bag, which is applied in ground mining, earthwork drilling, underground mining, etc., can solve the problems of vertical deep hole easily passing through the broken zone, difficulty in mechanization of explosives, and high technical requirements for rock drilling, so as to achieve high production efficiency. The effect of large capacity, reducing the requirement of ore body regularity and high mining efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The following will describe an embodiment of a vertical deep hole spherical drug bag ore dropping method according to the present invention with reference to the accompanying drawings. As those skilled in the art would realize, the described embodiments may be modified in various different ways, all without departing from the spirit and scope of the present invention. Accordingly, the drawings and description are illustrative in nature and not intended to limit the scope of the claims. Also, in this specification, the drawings are not drawn to scale, and like reference numerals denote like parts.

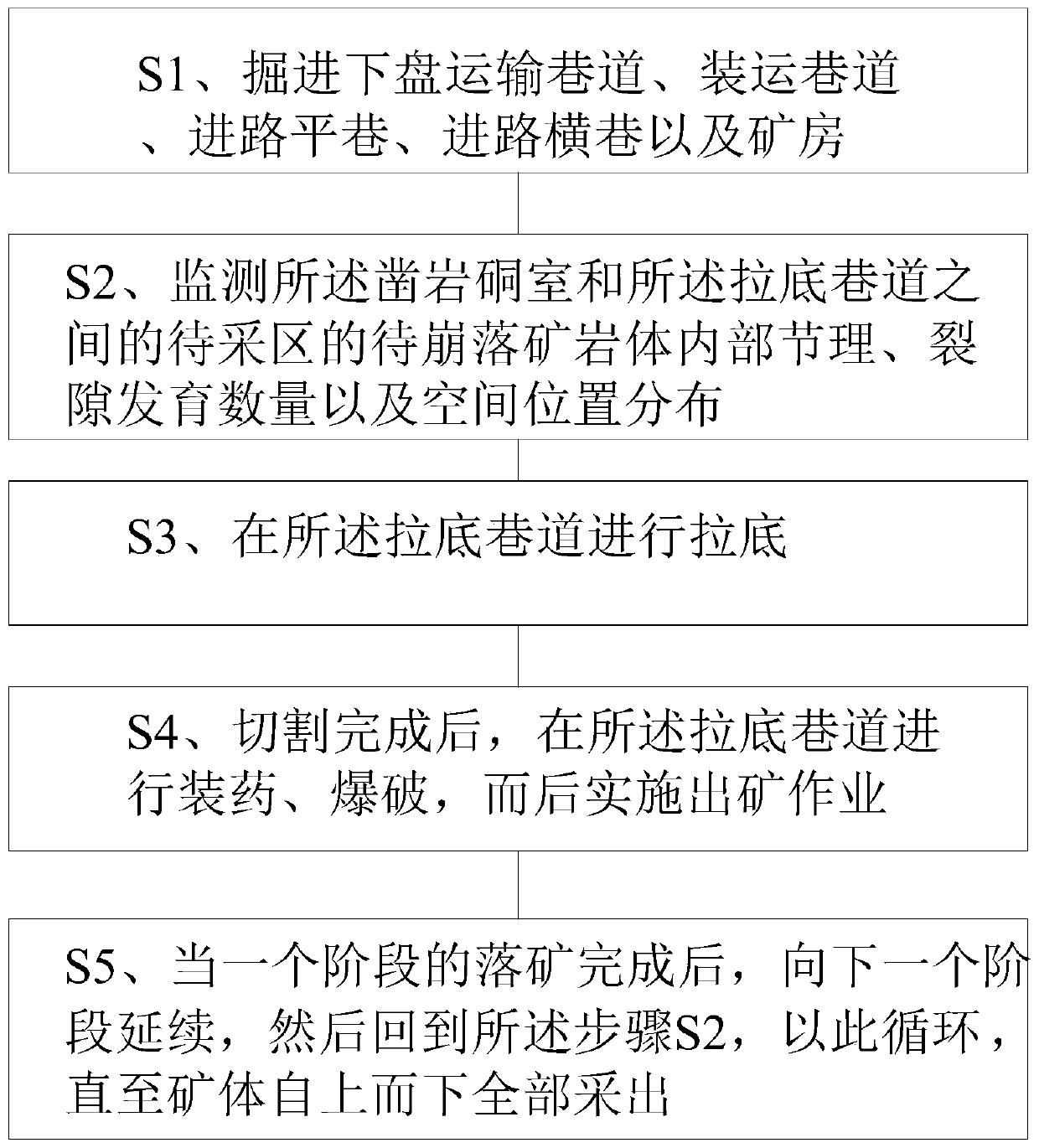

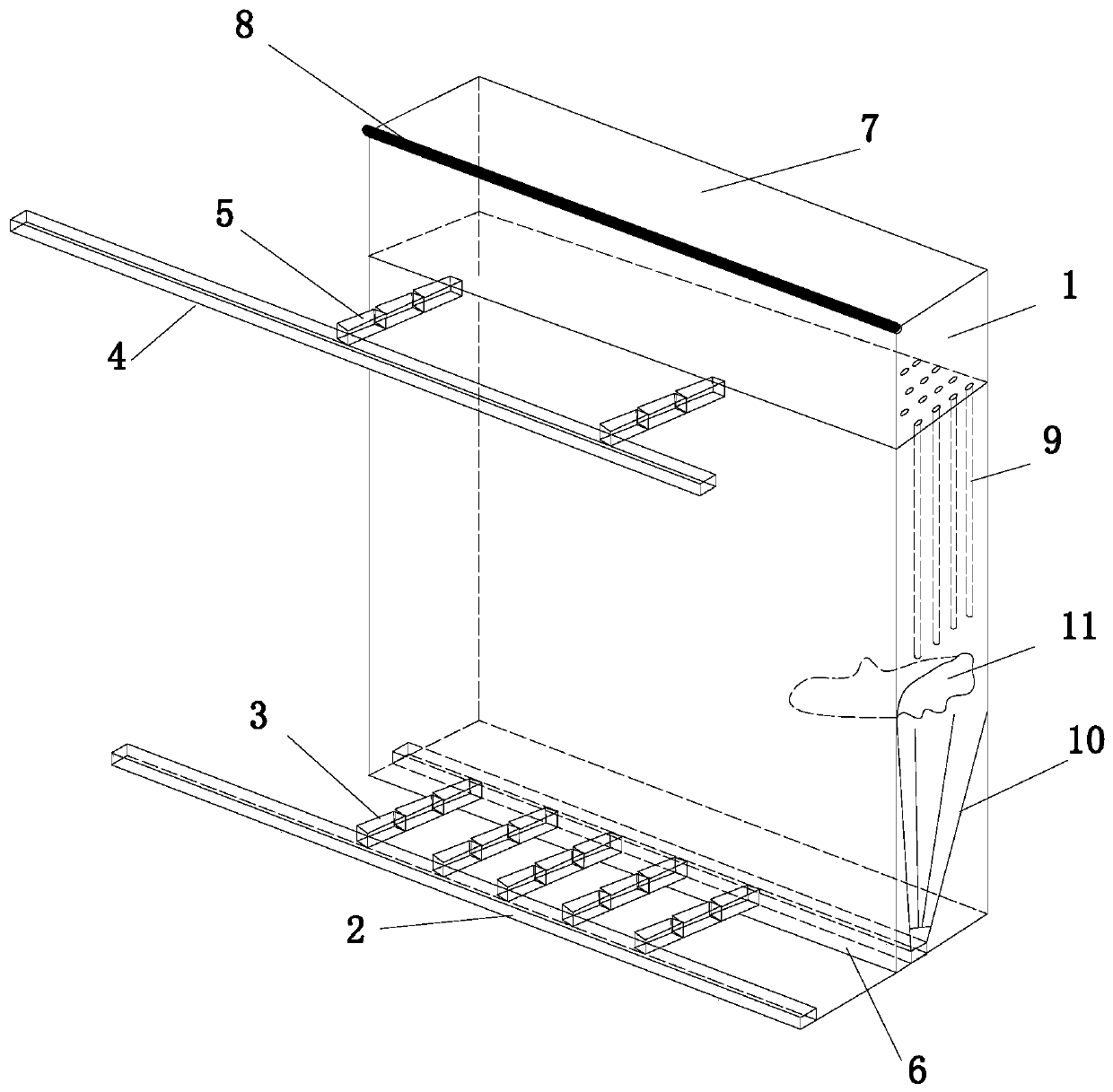

[0018] figure 1 It is a flow chart, showing the process of the vertical deep hole spherical drug bag ore dropping method described in one embodiment of the present invention, figure 2 It is a schematic diagram, showing the structure of the vertical deep-hole spherical drug bag drop mine house described in one embodiment of the present invention. like figure 1 and figur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com