Two-step mechanization cooperative high-section non-solid waste mining process for controlling ground pressure house column

A high-section, room-and-pillar technology, applied in ground mining, underground mining, mining equipment, etc., can solve problems such as ineffective control of stope roof pressure and low degree of mechanization, and achieve efficient mining, high degree of mechanization, and safe mining sex high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

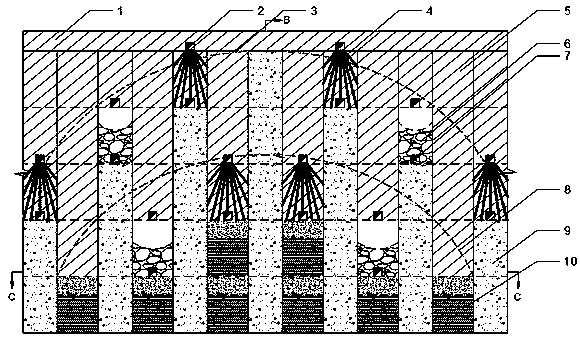

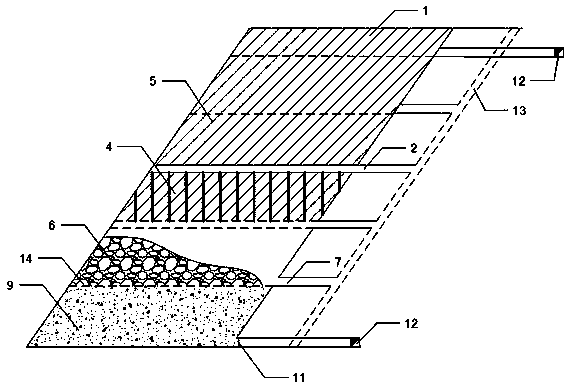

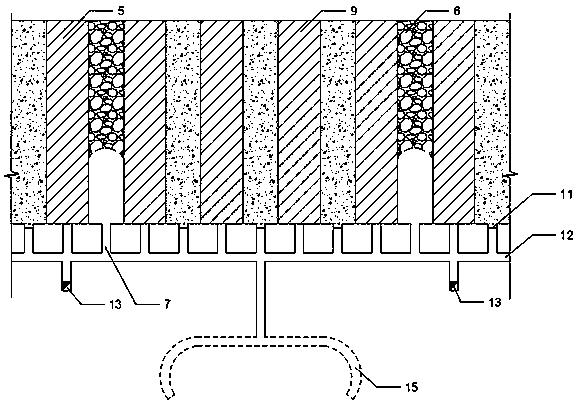

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0027] Such as Figure 1~3 As shown, the present invention proposes a two-step mechanized cooperative high-section solid-waste-free green mining process for controlling the ground pressure. The present invention will be further described in detail in conjunction with the accompanying drawings and specific implementation examples:

[0028] A mine in Shandong is a gold mine, and the experimental ore section is a moderately stable ore body controlled by the fracture zone. The ore body is vein-shaped, with a strike length of 500m, a strike of 15°, and a dip angle of 55°. The average thickness of the ore body is 34m, and the gold grade is 2.15g / t. The experimental stope is selected for industrial experiments. The experiment implements a two-step method of controlling the ground pressure room and pillar Mechanized collaborative high-sectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com