Boundary-controlled room column type sublevel open stoping subsequent stage filling mining method

A backfill mining method and room-and-pillar technology, which can be used in backfill, surface mining, mining equipment, etc., and can solve problems such as potential safety hazards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

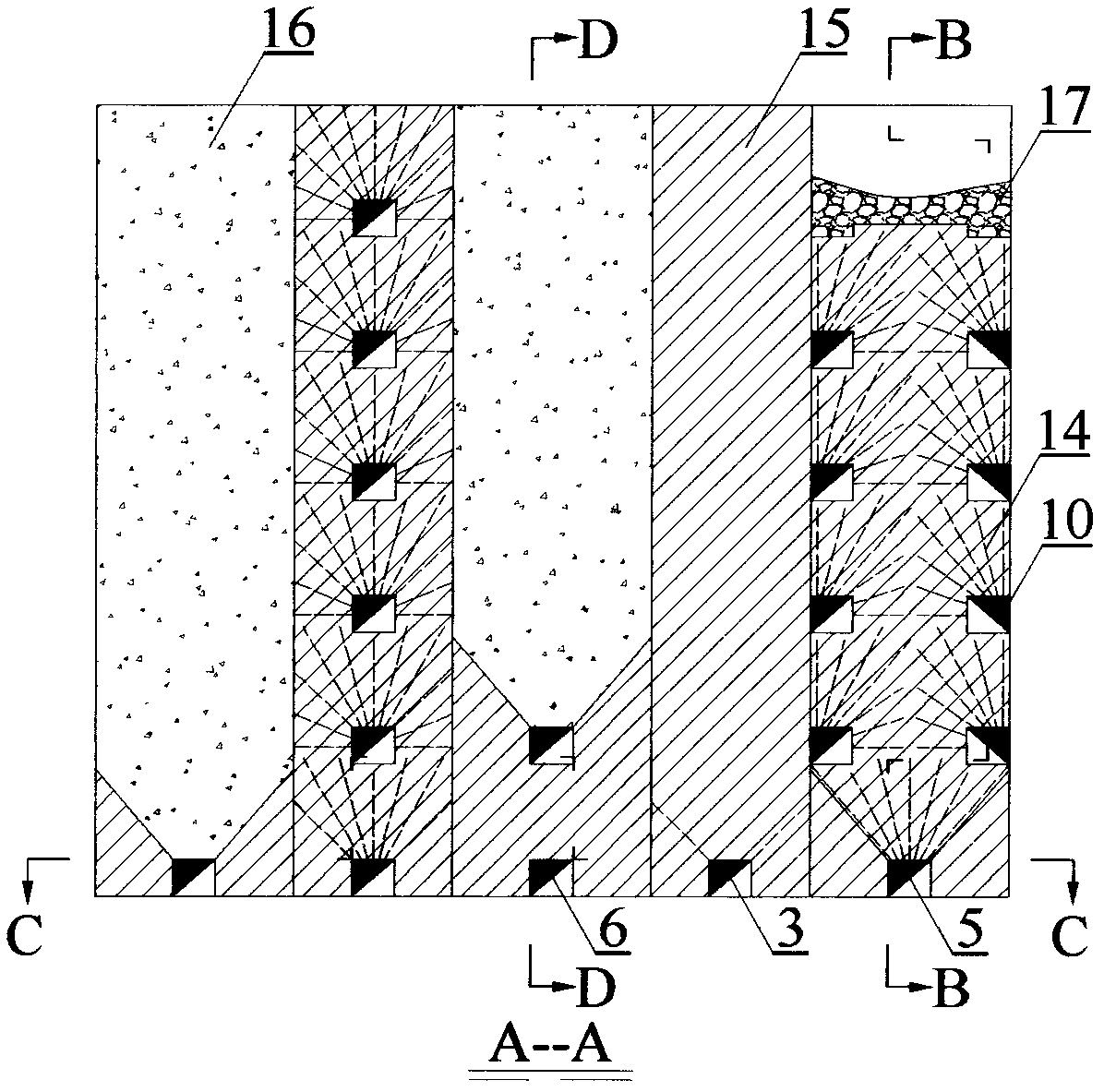

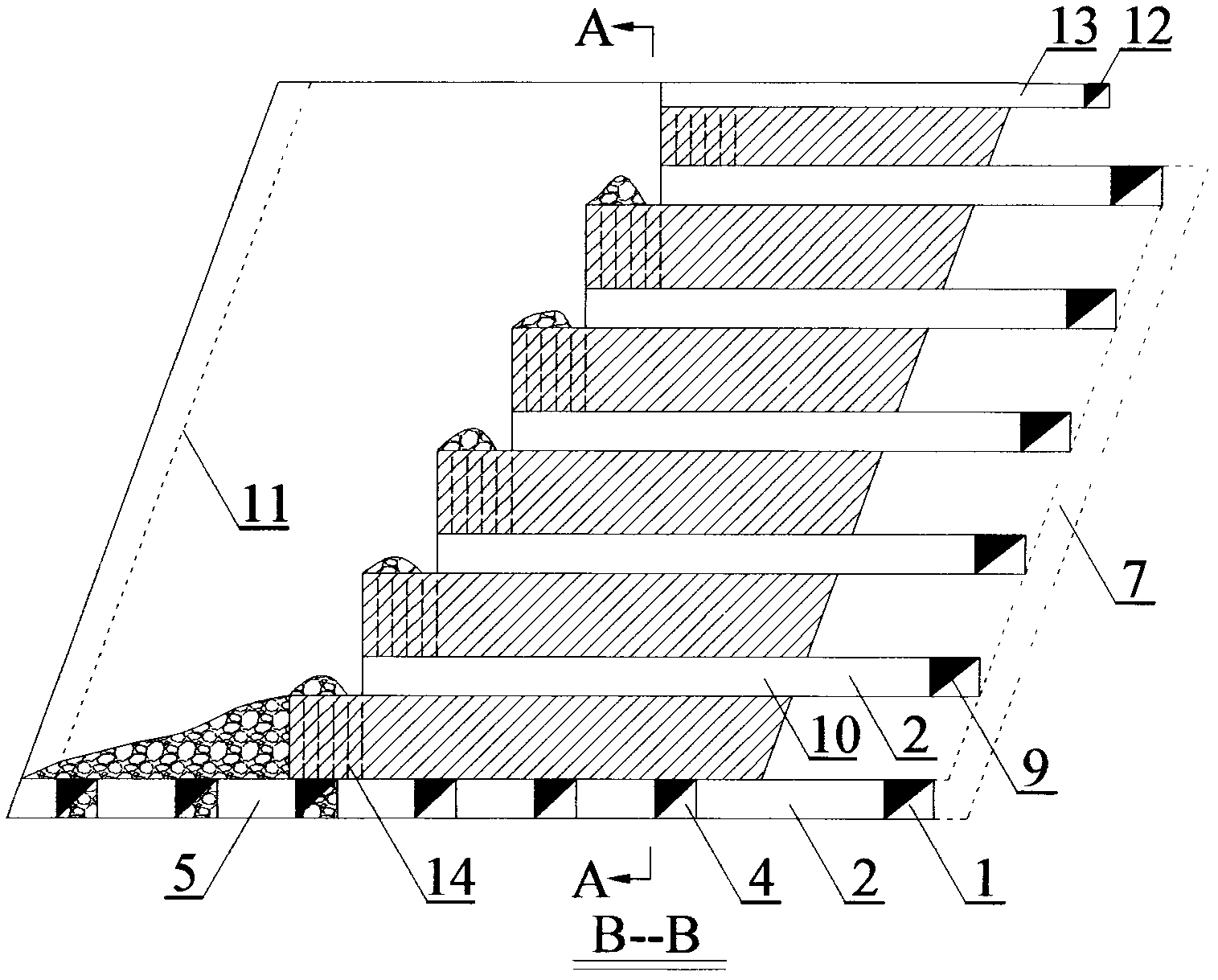

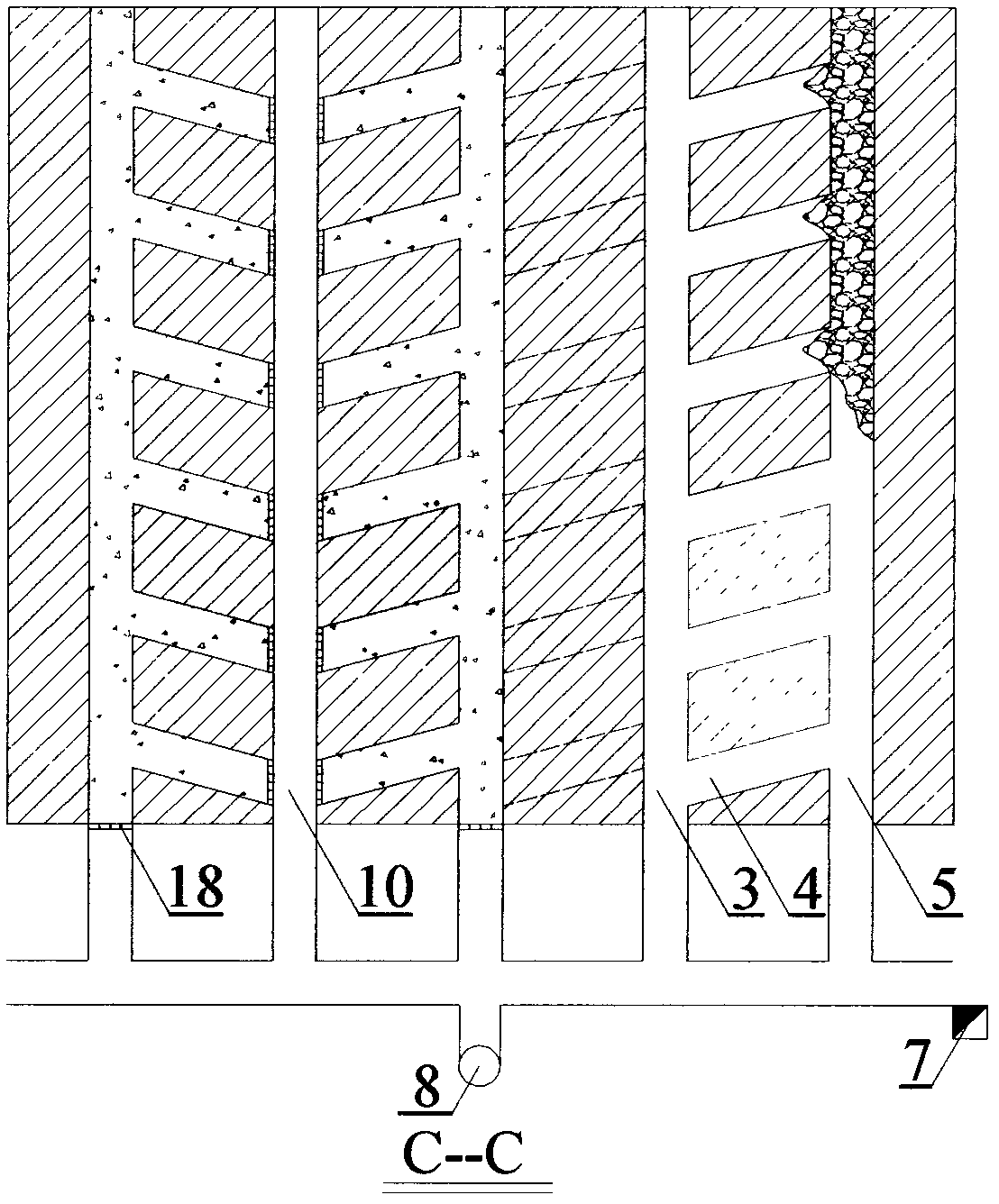

[0021] Specific use cases for the proposed mining method of the present invention are:

[0022] (1) Divide the ore body seamless pillars into panel areas, three mine houses with a width of 15m and two ore pillars with a width of 12m are arranged without interruption in the panel area. The length of the stope is equal to the thickness of the ore body. The mining sequence of Mining 1" is first the mining room and then the mining pillar; the length of the panel is 69m, the vertical height is 60m, and the vertical height of the sections is 10m, and the sections are connected by connecting roads and inclined shafts outside the vein.

[0023] (2) Mining project: stage transportation level roadway 1→connecting roadway 2→rock drilling and ore exiting horizontal roadway 3→ore exiting road 4→rock drilling and ore collecting horizontal roadway 5→ore exiting horizontal roadway 6→pedestrian inclined shaft 7→sliding Mine 8→Segmented entryway 9→Rock drilling horizontal entryway 10→Cutting ve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com