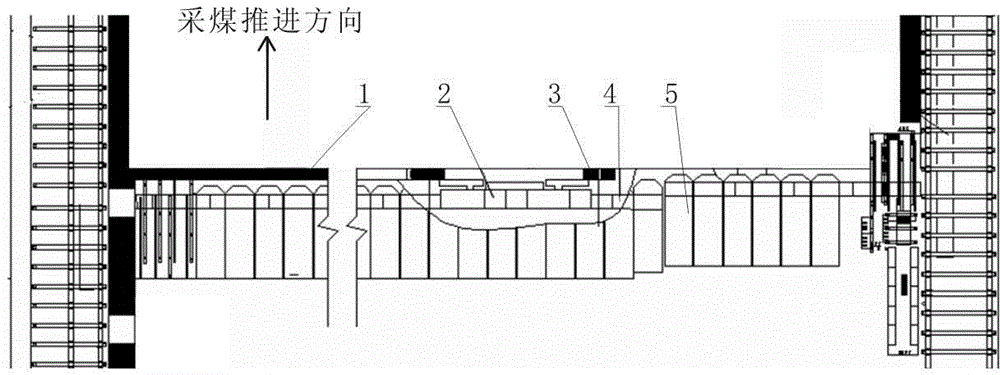

High-efficiency thin coal seam complete-set coal mining equipment and coal mining method

A coal mining method and thin coal seam technology, applied in ground mining, earth square drilling, underground mining, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

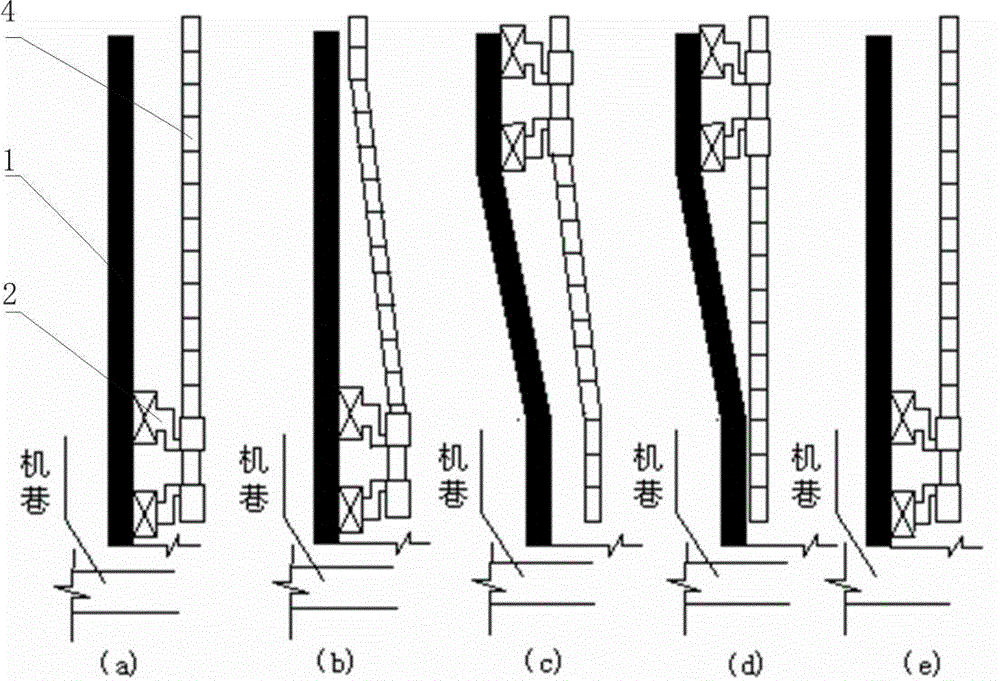

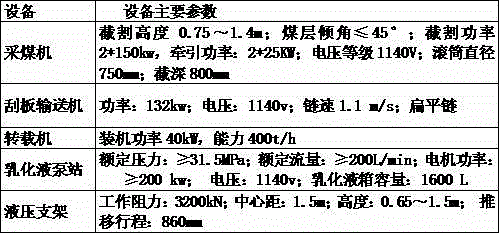

Embodiment Construction

[0034] The shearer 2 of the present invention has two supporting feet on the coal wall side and two semi-enclosed track grooves arranged on the side of the old pond, a total of four supporting points. The supporting foot on the coal wall side can be rotated at a certain angle. The lower surface is supported on the shovel plate of the scraper conveyor, and the upper surface is hooked under the rack. The supporting foot can realize the freedom of the shearer in three directions; The track groove of the guide device on the side of the pond is hinged on the bridge by a pin shaft, and can be rotated at a certain angle to adapt to the undulation of the coal seam floor. The track groove and the pin row of the scraper conveyor are buckled together with a certain gap between them. Limit the freedom of the shearer in four directions. The traveling gear and the rack are matched with each other to act as the traveling drive of the shearer, and the drive end is arranged on the side of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com