Diskless region type connection roadway continuous sectional cut-and-filling stoping method shared by chamber and jambs

A backfill mining method, a panelless technology, applied in the fields of backfill, surface mining, mining equipment, etc., can solve the problems of large mining accuracy and increased mining cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Example Take the middle section of +750m~+700m of Maluping Mine of Guizhou Kailin Group Mining Corporation as an example.

[0024] The specific implementation steps are as follows:

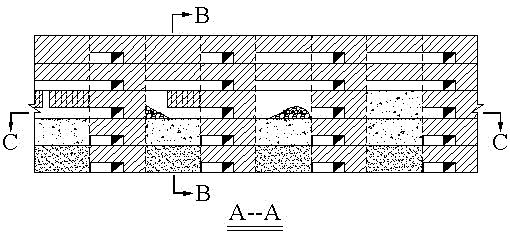

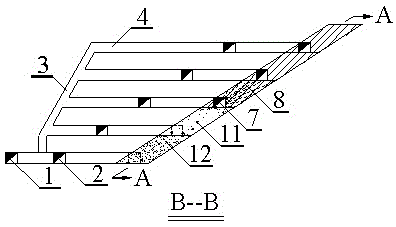

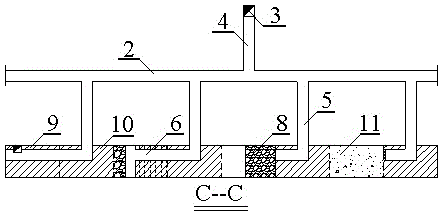

[0025] 1. Divide the ore body into the middle section, the vertical height of the middle section is 50m, and the vertical height of the subsection is 10m; in the middle section, a spiral ramp is used to connect the subsection transportation roadways along the ore body, and the subsections are divided into ore houses and pillars without intervals , the width of mine pillars is 20m, the height is segmented vertical height of 10m, and the oblique length is 18.36m.

[0026] 2. Mining standard project: middle section transportation level roadway 1 → segmental level roadway outside the vein 2 → chute 3 → chute connection road 4 → mine exit road 5 → along the vein rock drilling roadway 6 → cutting up the mountain 7, arranged every 200m A mine shaft.

[0027] 3. Mining process:

[0028] (1) Rock...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com