Mining method for steep-dip thin ore body

A mining method and technology for thin ore bodies, which are applied in the mining field of steeply inclined thin ore bodies, can solve the problems of poor operation safety, low production capacity, and large ground pressure activities.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Include the following steps:

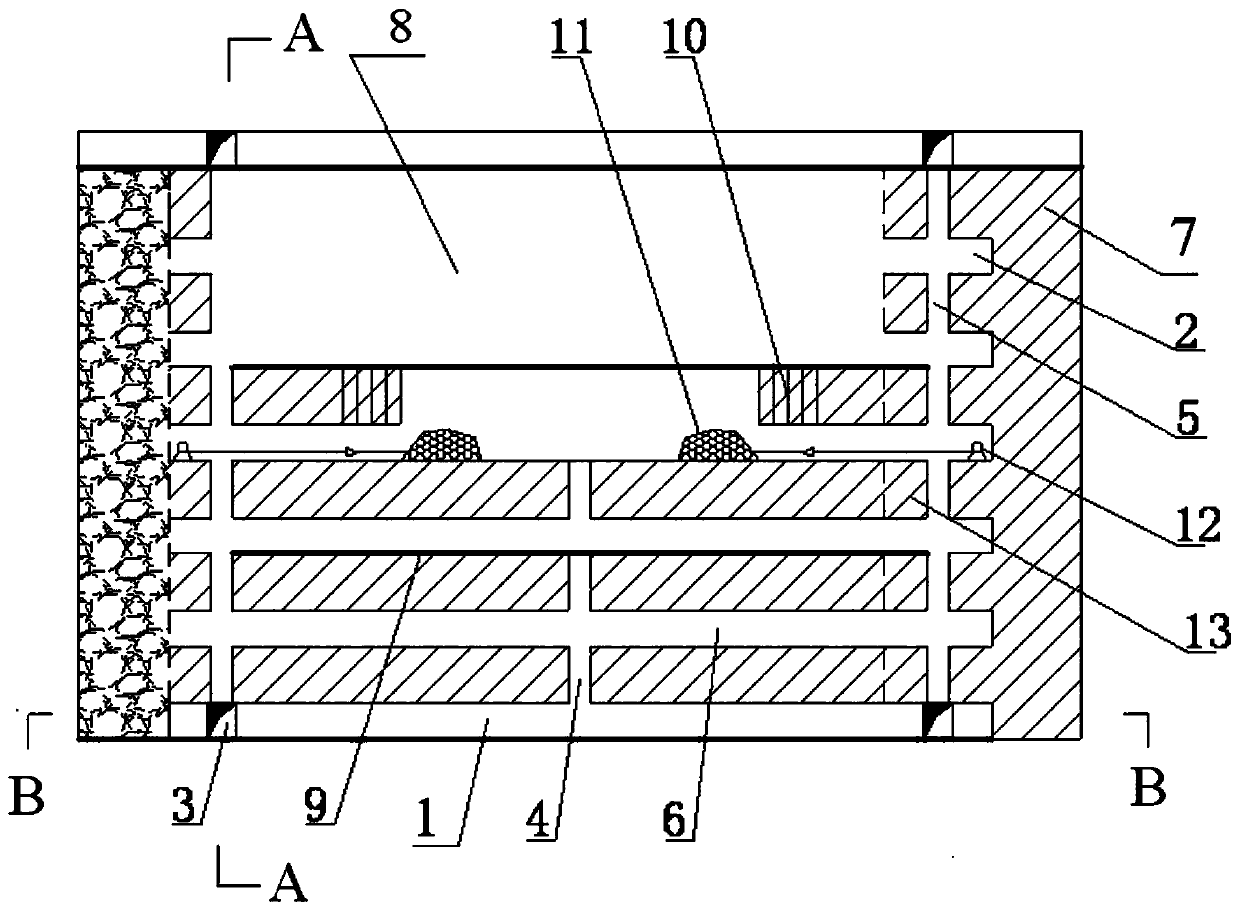

[0024] In the first step, the ore body 7 is divided into ore blocks, the length of the ore block is 40m, and the height is 20m. Only a small amount of intercolumns 13 are left in the ore block, and the interior of the ore block is segmented, and each section has a height of 6m, 7m, and 7m;

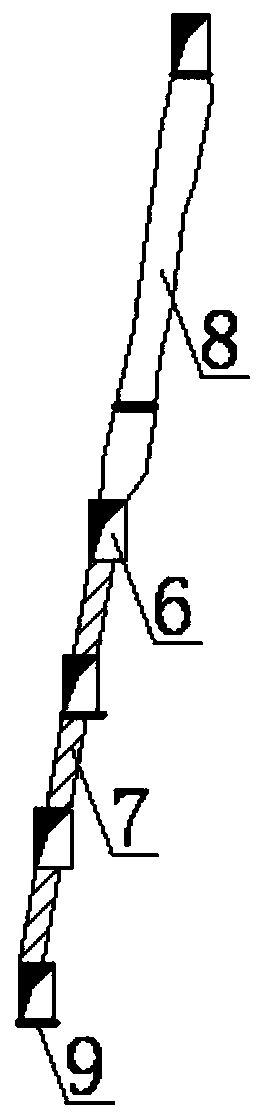

[0025] In the second step, at the two ends of the ore block, the vertical ore body strike direction of the transport roadway 1 outside the vein is excavated into the vein-piercing roadway 3; Segmental rock drilling roadway 6; after the segmental rock drilling roadway excavation is completed, excavate the central advanced patio 4;

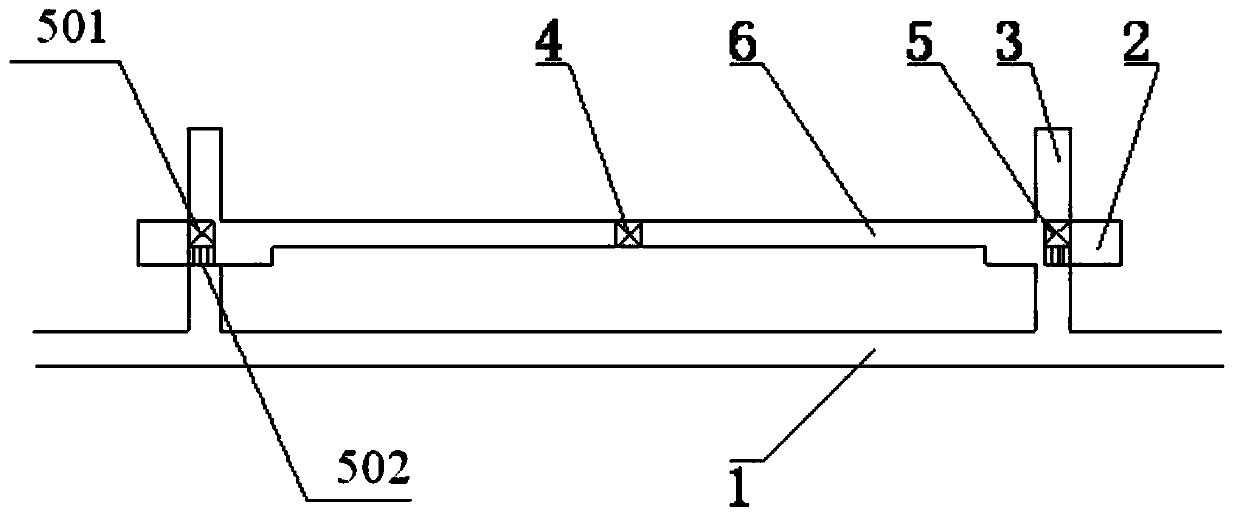

[0026] In the third step, the ore mining sequence is from top to bottom, with the central advanced patio 4 as the free surface, and mining from the center to both ends; , the ore 11 that has collapsed during blasting is raked to the corresponding chute part 501 by electric rake 12, and released from the ore-drawing funnel o...

Embodiment 2

[0036] Include the following steps:

[0037] In the first step, the ore body 7 is divided into ore blocks, the length of the ore block is 70m, and the height is 80m. Only a small amount of intercolumns 13 are left in the ore block, and the interior of the ore block is segmented, and each section has a height of 8m;

[0038] In the second step, at the two ends of the ore block, the vertical ore body strike direction of the transport roadway 1 outside the vein is excavated into the vein-piercing roadway 3; Segmental rock drilling roadway 6; after the segmental rock drilling roadway excavation is completed, excavate the central advanced patio 4;

[0039] In the third step, the ore mining sequence is from top to bottom, with the central advanced patio 4 as the free surface, and mining from the center to both ends; , the ore 11 that has collapsed during blasting is raked to the corresponding chute part 501 by electric rake 12, and released from the ore-drawing funnel of the chute;...

Embodiment 3

[0049] Include the following steps:

[0050] In the first step, the ore body 7 is divided into ore blocks, the length of the ore block is 100m, and the height is 100m. Only a small amount of intercolumns 13 are left in the ore block, and the interior of the ore block is segmented, and each section has a height of 10m;

[0051]In the second step, at the two ends of the ore block, the vertical ore body strike direction of the transport roadway 1 outside the vein is excavated into the vein-piercing roadway 3; Segmental rock drilling roadway 6; after the segmental rock drilling roadway excavation is completed, excavate the central advanced patio 4;

[0052] In the third step, the ore mining sequence is from top to bottom, with the central advanced patio 4 as the free surface, and mining from the center to both ends; , the ore 11 that has collapsed during blasting is raked to the corresponding chute part 501 by electric rake 12, and released from the ore-drawing funnel of the chut...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com