Mechanized benching room-and-pillar mining method

A mining method and step-type technology, applied in the field of mechanized step-type room-and-pillar mining method, can solve the problems of low level of mechanization in stope production operations, high labor intensity of workers, small effective raking distance of electric rakes, etc., so as to reduce pedestrian ventilation. The amount of climbing and cutting works, the labor intensity of workers is reduced, and the effect of reducing the effect of cutting works

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

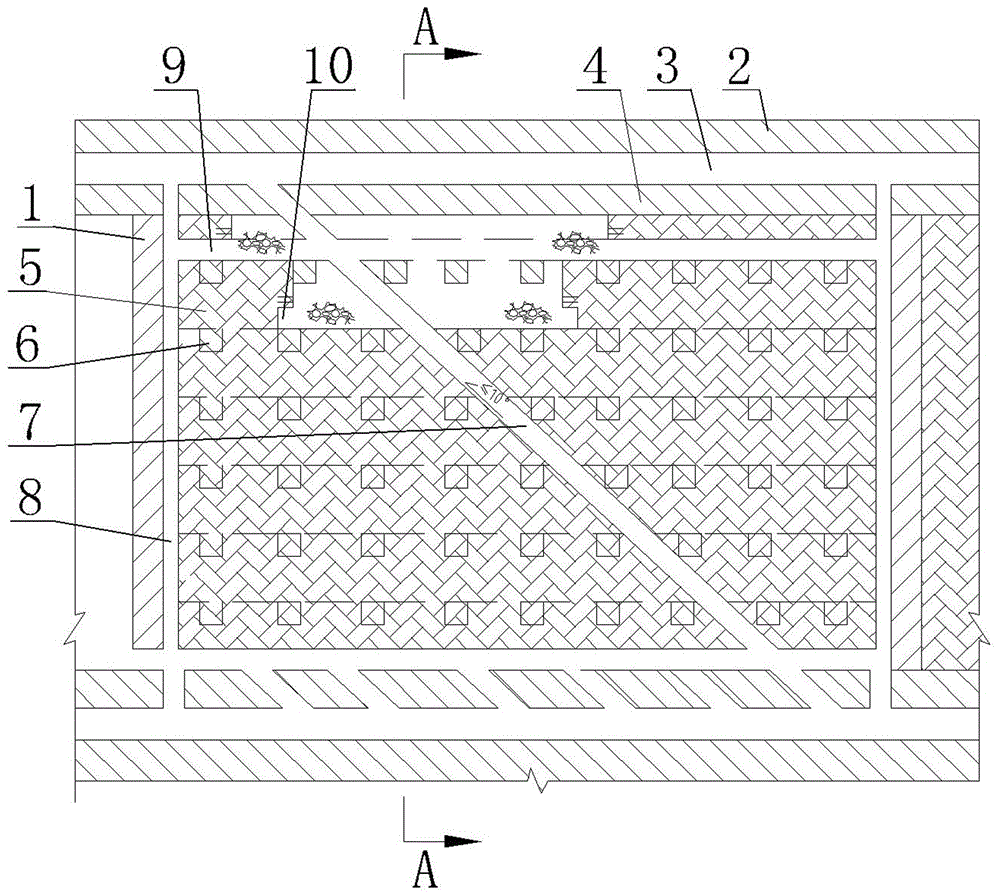

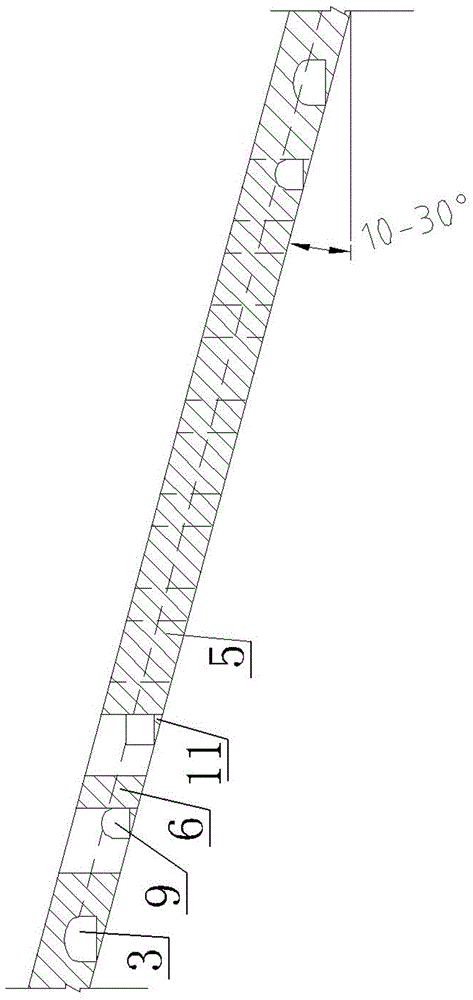

[0037] from figure 1 and figure 2 As can be seen, this mechanized stepped room-and-pillar mining method of the present invention comprises the following steps:

[0038] (1) Stope layout: The stope is arranged along the ore body trend, the height of the middle section is 20-30m, the length of the stope along the strike is 100-120m, the oblique length of the stope is not more than 80-100m, and 4-30m is reserved between the stopes along the inclination. A 6m wide intercolumn 1, a mid-section transportation lane 3 is arranged between the upper and lower adjacent middle sections, and a top column 4 and a bottom column 2 are reserved. The bottom column is 4-6m wide, and the top column is 4-6m wide; , Divide the ore body along the strike into subsections 5 for mining, the width of the subsections is 6-8m, and set point columns 6 between the subsections 5, the size of the point columns is 3m×3m~4m×4m, and the distance between the point columns along the ore body 8~10m, the distance...

Embodiment 2

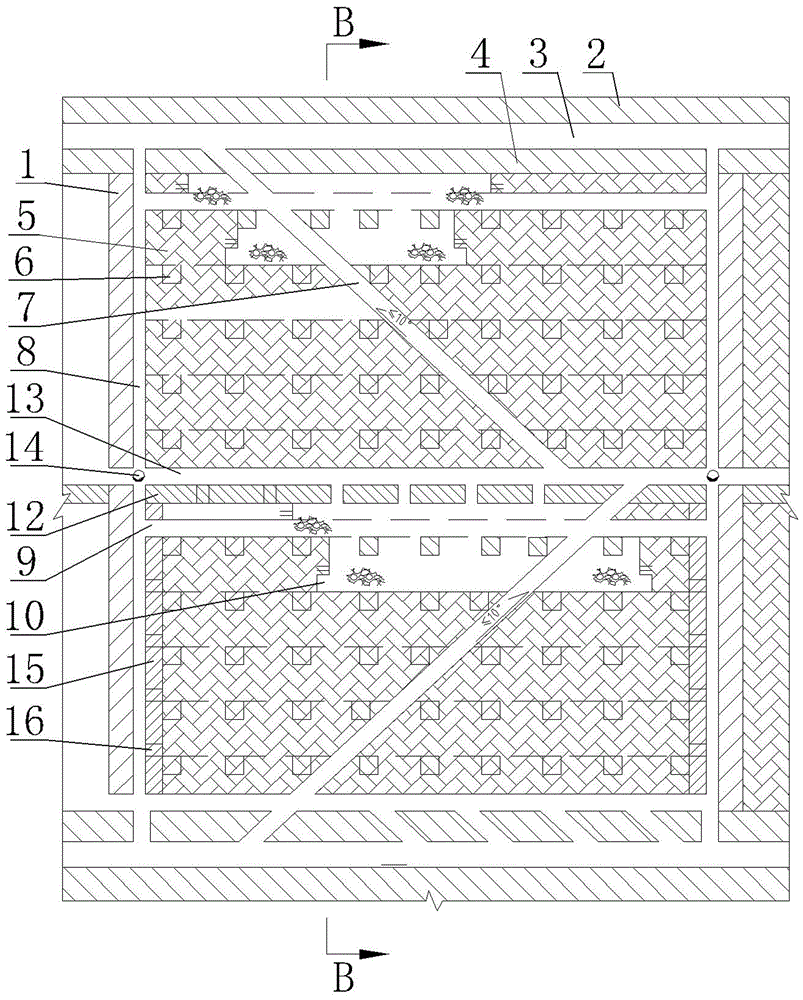

[0045] from image 3 and Figure 4 As can be seen, this mechanized stepped room-and-pillar mining method of the present invention comprises the following steps:

[0046] (1) Stope arrangement: The stope is arranged along the ore body trend, the height of the middle section is 20-30m, the length of the stope along the strike is 100-120m, the slope length of the stope is greater than 80-100m, and 4-6m is reserved along the inclination between the stopes Wide inter-pillar 1, mid-section transport lane 3 is arranged between the upper and lower adjacent middle sections, and top column 4 and bottom column 2 are reserved. The width of the bottom column is 4-6m, and the width of the top column is 4-6m. The ore body is divided along the dip It is divided into upper and lower sections, and a continuous column 12 with a width of 4-6m is left between the sections; when the stope is mined, the ore body is divided into sub-sections 5 along the strike for mining, and the sub-section width i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com