Fan-shaped medium-diameter deep hole mining technology of steeply inclined medium-thick ore body

It is a fan-shaped medium-deep hole and steeply inclined technology, which can be used in surface mining, underground mining, special mining, etc. It can solve the problem of difficult to recycle the old engineering volume of mining and cutting projects, high requirements for rock drilling chamber support, and blasting hole network. Large parameters, etc., to achieve the effect of improving the efficiency of charge blasting operations, reducing mining accuracy and cutting engineering, and improving mining efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

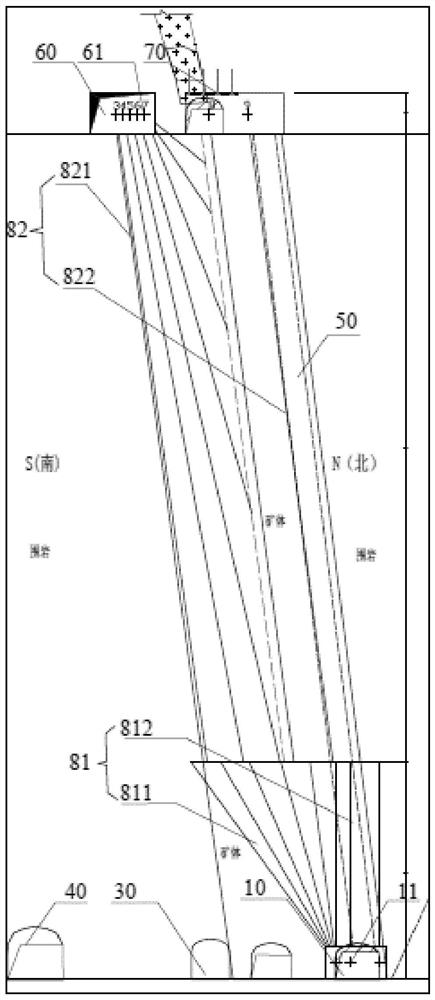

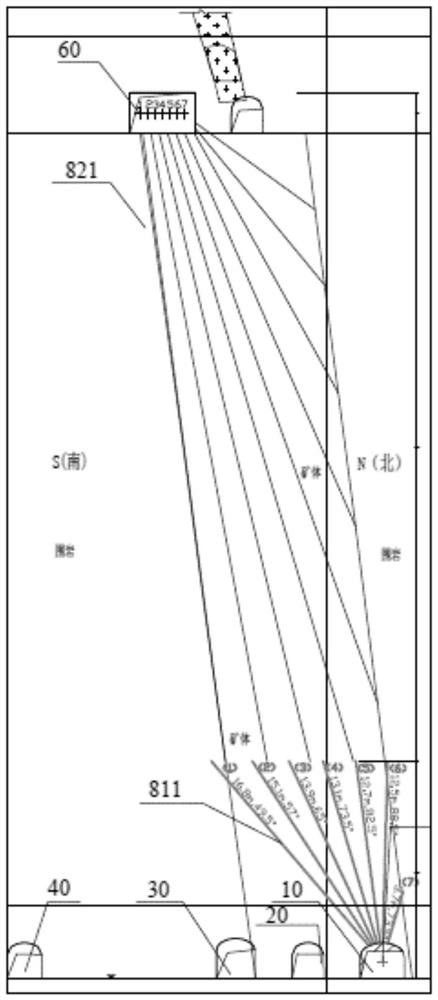

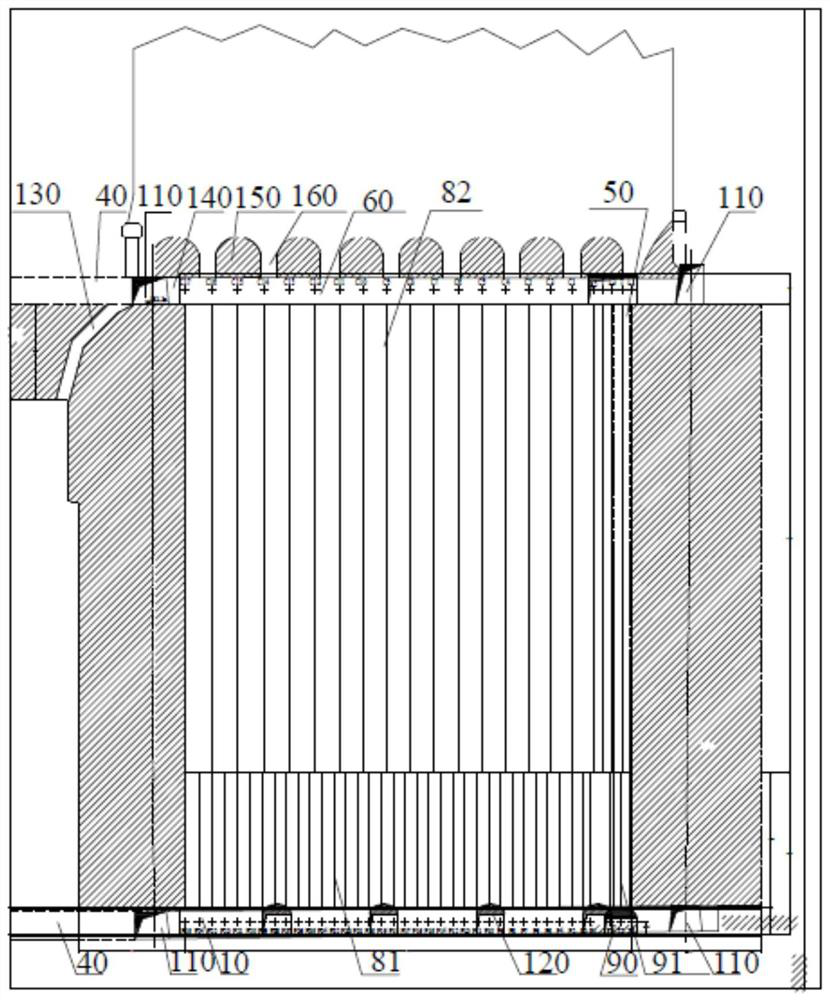

[0038] see Figures 1 to 3 As shown, it is a mining room layout diagram of a fan-shaped medium-diameter deep hole mining process with a steeply inclined medium-thick ore body. The specific mining process is as follows:

[0039] (1) Ore block layout: The ore blocks are arranged along the east-west trend of the ore body, inclined to the north, with an inclination angle of about 83°, a strike length of 50m, and an average width of 10.9m. 4.5m wide intercolumns are left on the east and west sides, and the mining strike is about 41m long; no top columns are left.

[0040] (2) Mining and cutting: The mining project has 40 along-vein transportation lanes (recycling old) and 60 rock drilling chambers in the upper middle section of the stope; 30 mine level lanes, 120 ore loading access roads, 10 bottom level lanes, one-sided V-shaped ore-receiving cutting ditch, and 15m bottom height; cutting works include bottom level lanes 10, top cutting horizontal lanes 70, and bottom cutting hori...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com