Full-staged combination drilling with blasting mining method

A mining method and stage technology, which is applied in the field of high-efficiency mining with full-stage combined chisel blasting, can solve the problems of high hole depth, deflection rate, high stability requirements of ore rock, and large mining and cutting engineering volume, and achieve accurate mining engineering volume less, less mining and cutting engineering, saving investment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

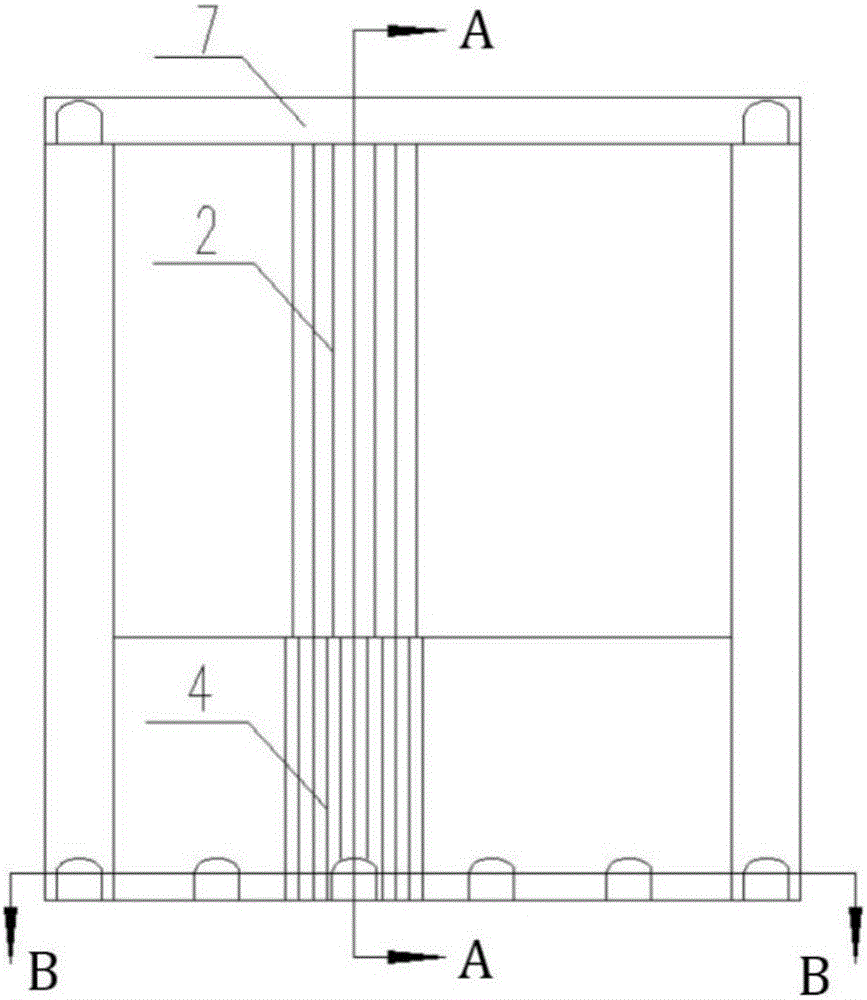

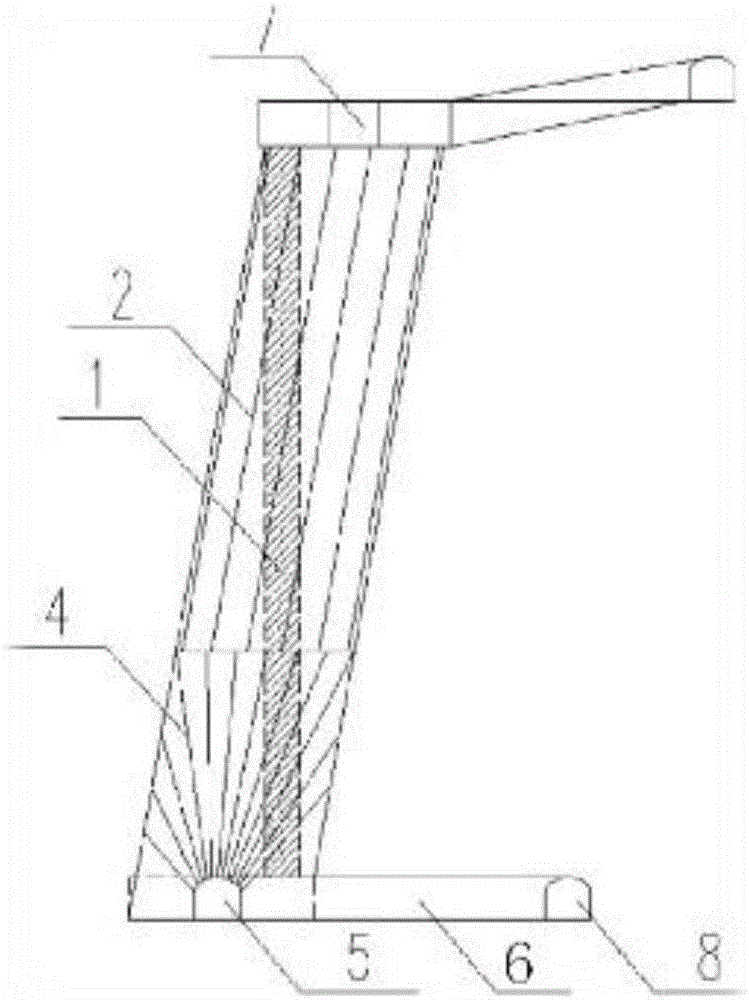

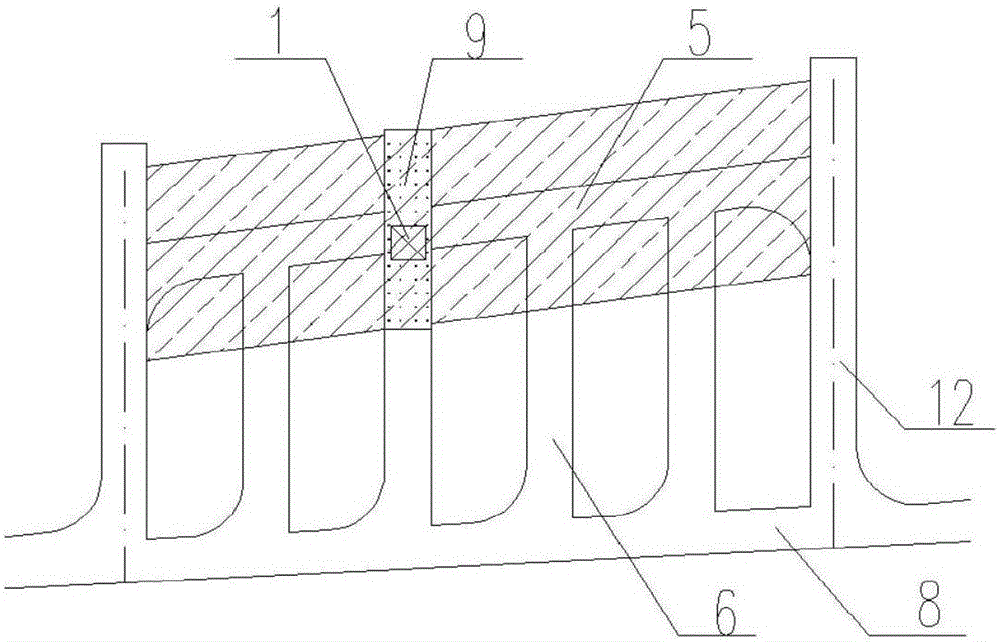

[0029] see Figure 1-5 , in the embodiment of the present invention, the high-efficiency mining method for all-stage combined chisel blasting and mine removal includes the following steps:

[0030] (1) Structural parameters of the mine house: it is assumed that the mine house is arranged along the direction of the ore body. 20m (16m for the experimental mine).

[0031] (2) Mining and cutting: the bottom of the mining house is equipped with a stage transportation roadway 8 (25m away from the ore body), a mine exit roadway 6 (15m apart), a cutting bottom roadway 5, etc.; the cutting bottom roadway 5 is used as the lower fan-shaped In the construction space of the deep hole 4, the fan-shaped middle and deep hole 4 is drilled upwards, and the bottom of the trench is formed after blasting. On one side or in the middle of the mine house, a large-diameter deep hole 2 is blasted to form a cutting patio 1, and then a cutting groove is formed from the cutting patio 1 as a compensation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com