Mining method for treating upward pinch-out of inclined thin ore body

A mining method and thin ore body technology, which is applied to the mining field where thin ore bodies gradually pinch out upwards, can solve problems such as large mining and cutting engineering volumes, and achieve the goals of improving safety, reducing mining and cutting engineering volumes, and increasing production capacity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The embodiment of the inventive method is described in detail below:

[0011] An embodiment of an upward pinch-out mining method for processing inclined thin ore bodies:

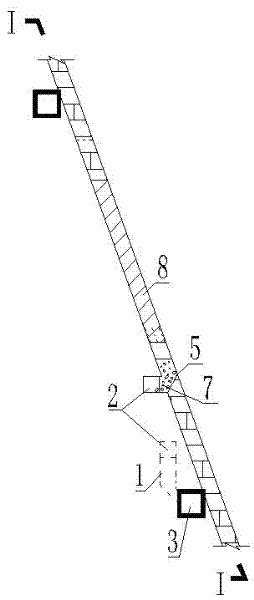

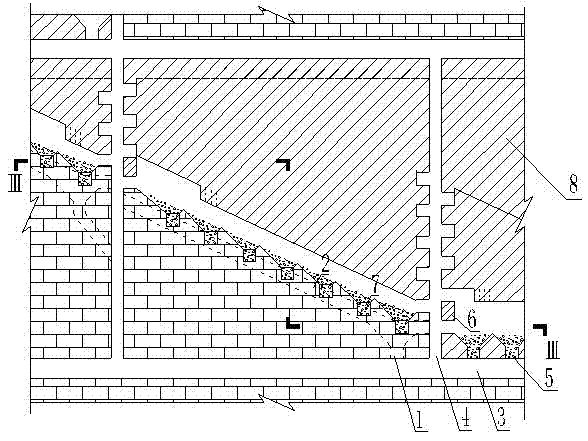

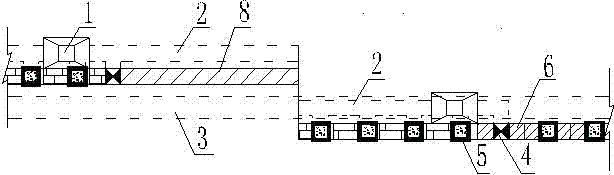

[0012] The ore block composition is arranged along the strike, with a length of 50m, a height of 50m in the middle section, and a height of 3m for the top column. When the upper return air tunnel does not need to be preserved and the surrounding rock is stable, and safety conditions permit, the top column may not be retained. The height of the base column is 4m, and the width of the inter-columns is 6m.

[0013] The mining and cutting work mainly includes the transportation roadway 3, the mining standard shaft 4, the electric rake road 2, the ore-drawing short chute 1, the funnel 5 and the bucket wear 7 during the excavation stage; the cross-section of the transportation level roadway 3 in the stage is 2200mm×2500mm; 4 section is 2×2 m 2 , the cross-section of electric rake road 2 is 2×2 m 2 A shor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com