Stoping blast mining process for thick and large ore body

A thick and large ore body and process technology, applied in blasting, surface mining, underground mining, etc., can solve the problems of high dilution rate of end mining, difficult recovery of boundary ore, and low mining efficiency, so as to improve the efficiency of each row of deep holes. The effect of blasting the amount of ore, reducing production costs, and low mining costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

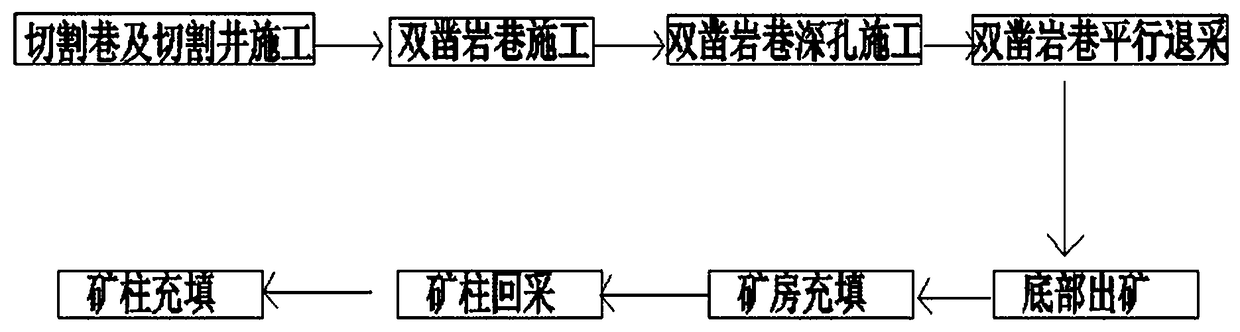

[0024] The back mining blasting mining technology of the thick ore body. The ore body of the thick copper mine is about 500m long, 25m wide, and 360m high. It is divided into multiple ore blocks, and each block is 36m long, 25m wide, The height is 60m, and the mining process specifically includes the following steps:

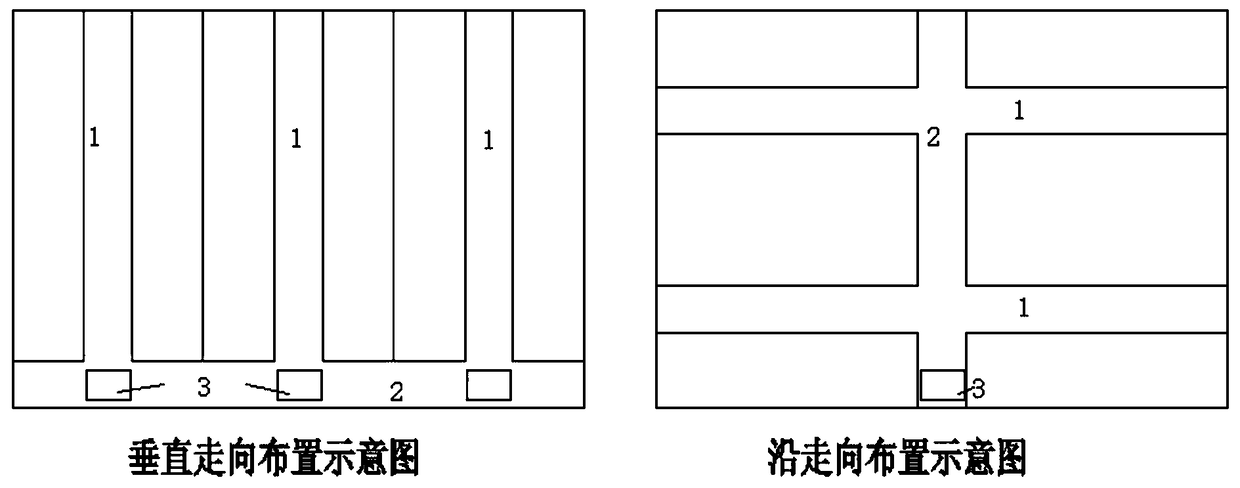

[0025] Step (1): Construction of cutting lane and cutting shaft: divide the main ore body into ore blocks in sequence according to the ore block structure, and construct cutting lane 2 at the end of the ore block. Cutting lane 2 is perpendicular to the direction of the ore body, and the cutting lane adopts a smooth surface Blasting is carried out by blasting, slag is discharged by electric scraper, cutting well 3 is vertically arranged at the bottom of the cutting lane, and the cutting well is constructed by raise drilling rig;

[0026] Step (2) Double rock drilling roadway construction: Arrange upper and lower layer rock drilling roadways on each ore block alon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com