A Novel Mining Method for Gently Dipping Thin-Medium Thick Orebodies

A mining method and gently inclined technology, which is applied in the new mining field of mining gently inclined thin-medium thick ore bodies, to achieve operational safety, realize mechanized operation of trackless equipment, and reduce difficulty and workload.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

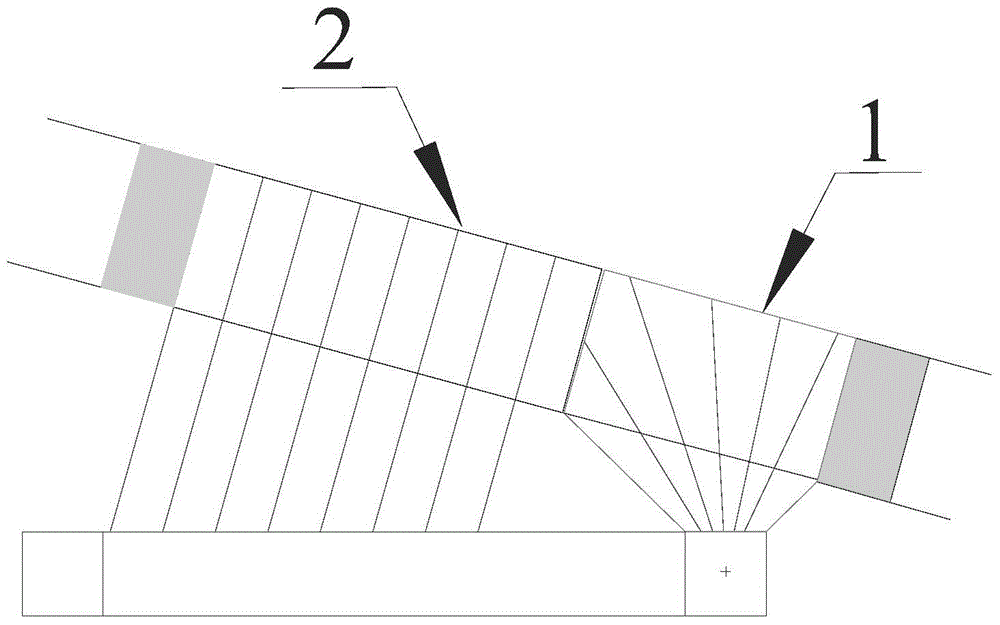

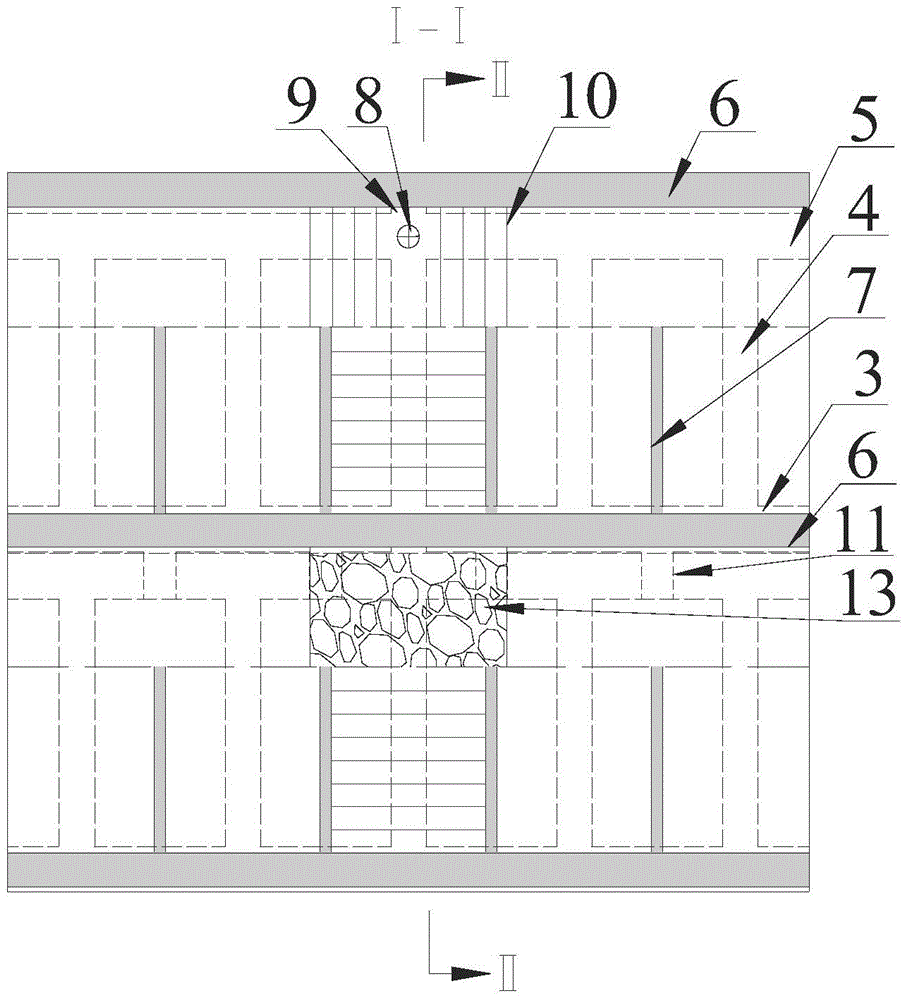

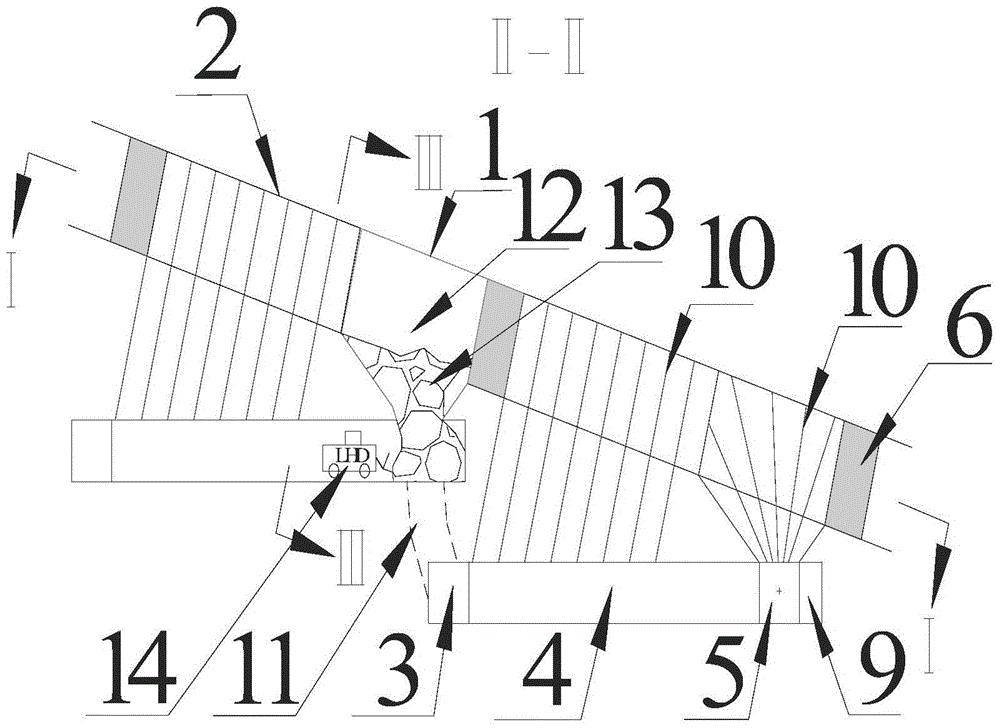

[0046] Due to the influence of folds, the occurrence of a certain copper ore body is complex and changeable. The ore body at the syncline axis is relatively gentle, and it continues to rise from the syncline axis to the two wings. The average dip angle of the syncline axis is 15°. The average body thickness is 6m. The roof of the ore body is argillaceous slate, which has good stability. When the stope span is not large, it can form an open field condition; the ore-bearing layer is dolomitic schist, and the structural plane of this rock mass is well developed, so local collapse and flaking are prone to occur , and easily weathered and cemented; the schist ore rocks in the transition zone of the ore body floor are relatively broken and have poor stability; the conglomerate and argillaceous quartzite in the chassis are relatively stable. To sum up, the occurrence of this ore body is changeable, the dip angle of the ore body is relatively slow, the rocks of the ore seam and the tr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com