Preparation method of lithium ion battery SnS2/CNTs/PPy composite anode material

A technology for lithium ion batteries and negative electrode materials, which is applied to battery electrodes, circuits, electrical components, etc., can solve the problems of unsatisfactory cycle performance and low capacity of lithium battery negative electrode materials, so as to improve cycle stability, improve electrical conductivity, improve The effect of overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] The present invention proposes a lithium ion battery SnS 2 / CNTs / PPy composite anode material preparation method, wherein, SnS 2 It is tin disulfide, CNTs is carbon nanotubes (Carbon nanotubes), PPy is polypyrrole, and the preparation method includes the following steps:

[0026] Step 1: Add SnCl 4 ·5H 2 Add O and thioacetamide (TAA) into the polyethylene glycol solution and stir well;

[0027] In step 1, the selected SnCl 4 ·5H 2 Both O and TAA were analytically pure, and SnCl 4 ·5H 2 The ratio of the amount of O and TAA substances is controlled at: SnCl 4 ·5H 2 O: TAA = 1:1;

[0028] Step 2: Add a certain amount of carbon nanotubes (CNTs) to the above solution, and ultrasonically disperse for 60 minutes;

[0029] In step 2, the mass of added CNTs is the theoretically obtained SnS 2 0.5%~10% of the alloy mass;

[0030] Step 3: transfer the solution obtained in step 2 into an automatic reaction kettle of polytetrafluoroethylene, carry out insulation treatmen...

Embodiment 1

[0039] Take 1.42 g SnCl 4 ·5H 2 O and 0.60 g of thioacetamide (TAA) were dissolved in 100 ml of polyethylene glycol (PEG 400) by stirring. After TAA was dissolved, 0.0070 g of carbon nanotubes were uniformly dispersed in the solution, and ultrasonically dispersed for 60 min. Finally, the above solution was transferred into an automatic polytetrafluoroethylene reactor and heated in an oven at 180°C for 18h. The cooled product was washed three times with deionized water and ethanol, and dried in vacuum at 80 °C for 24 h to obtain light yellow SnS 2 / CNTs composites.

[0040] The above SnS 2 / CNTs composite material was dissolved in 40ml deionized water, stirred for 30min, added 8mg sodium dodecyl sulfate and stirred for 30min, then added 104μL pyrrole monomer and 0.40g FeCl 3 ·6H 2 O, the mixed solution was stirred at room temperature for 4h. The obtained solution was separated by centrifugation, washed three times with deionized water and absolute ethanol, and the separa...

Embodiment 2

[0044] The difference between this example and Example 1 is: the mass of carbon nanotubes added is 0.0035g, the insulation condition in the automatic reactor is 180°C for 14h, the mass of sodium lauryl sulfate added is 24mg, pyrrole The amount of monomer is 82 μL, add FeCl 3 ·6H 2 The mass of O is 0.32 g, and the product is vacuum-dried at 100° C. for 6 h. Others are all the same as in Example 1.

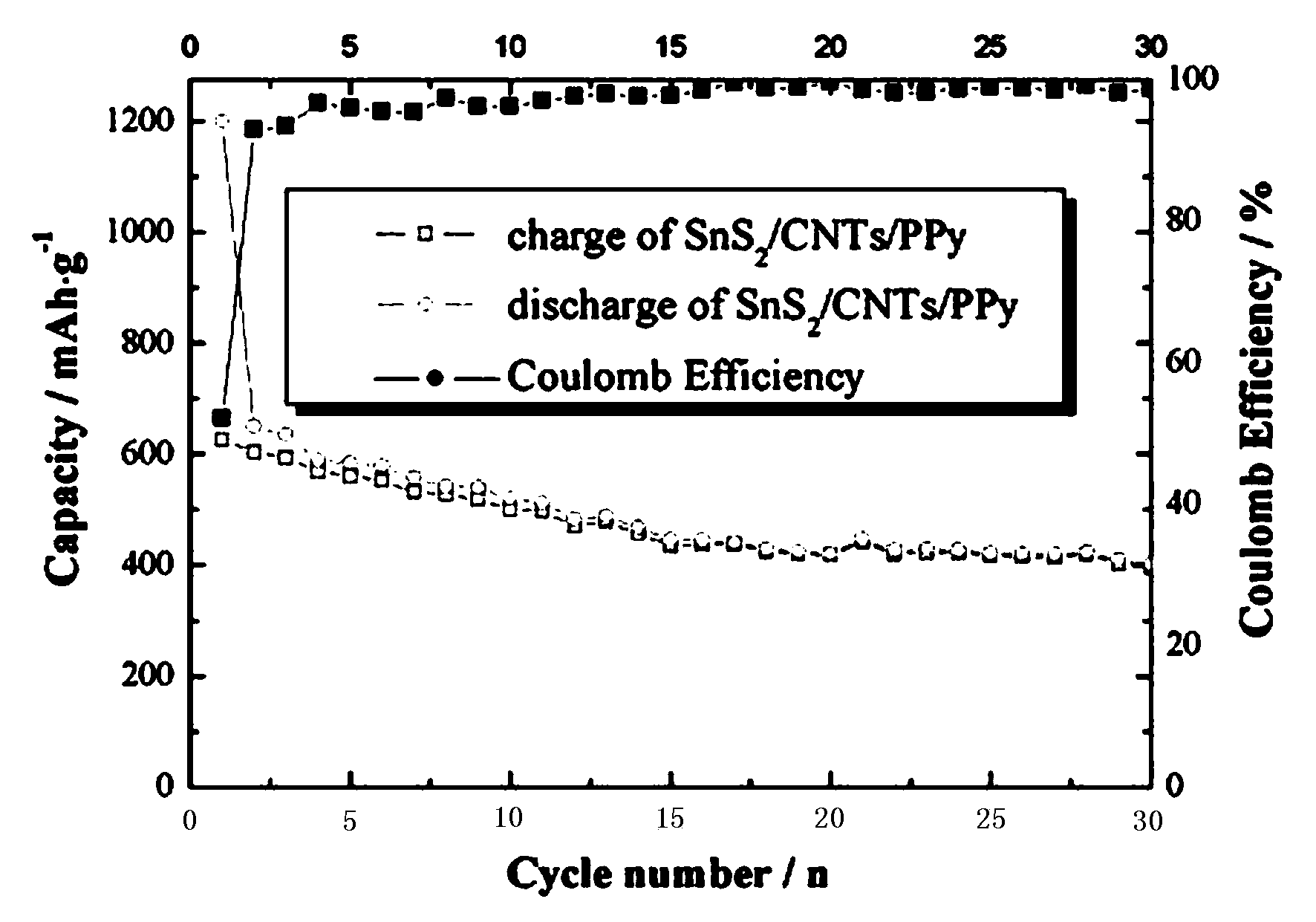

[0045] The constant current charge and discharge test of the composite negative electrode material described in this example shows that the electrochemical performance remains basically unchanged, and the initial discharge capacity is 1184 mAh g -1 , after 30 cycles, the reversible capacity can be maintained at 410mAh·g -1 .

[0046]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com