Sub-level shrinkage caving method

A caving mining and ore retention technology, which is applied in ground mining, underground mining, special mining, etc., can solve the problems of increased cost, large amount of mining engineering, and low efficiency, so as to reduce the rate of ore loss and the amount of mining and cutting Small, the effect of reducing mining costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The implementation of the present invention will be described in detail below in conjunction with the drawings and examples.

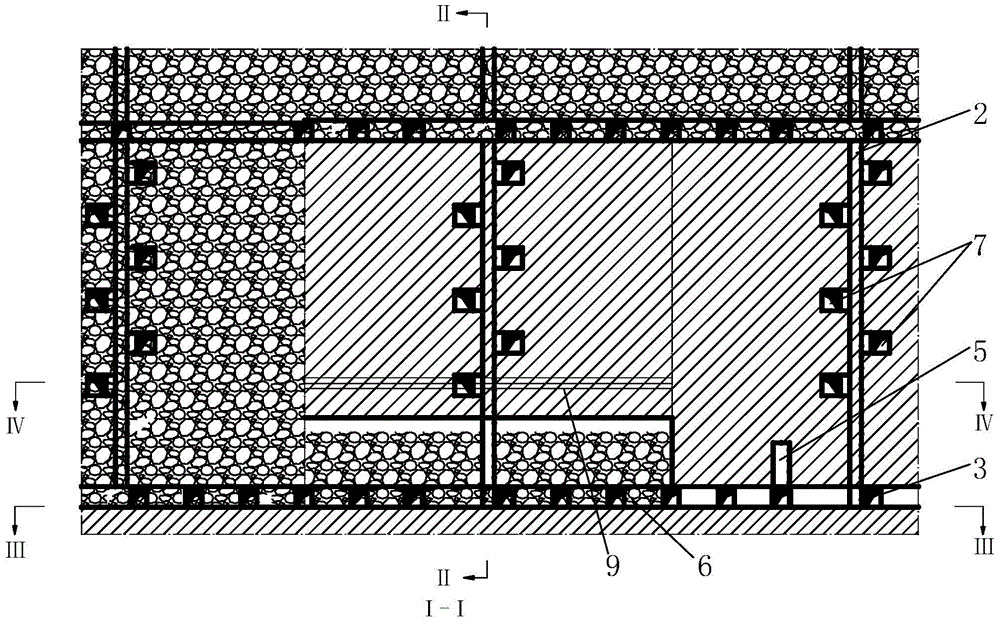

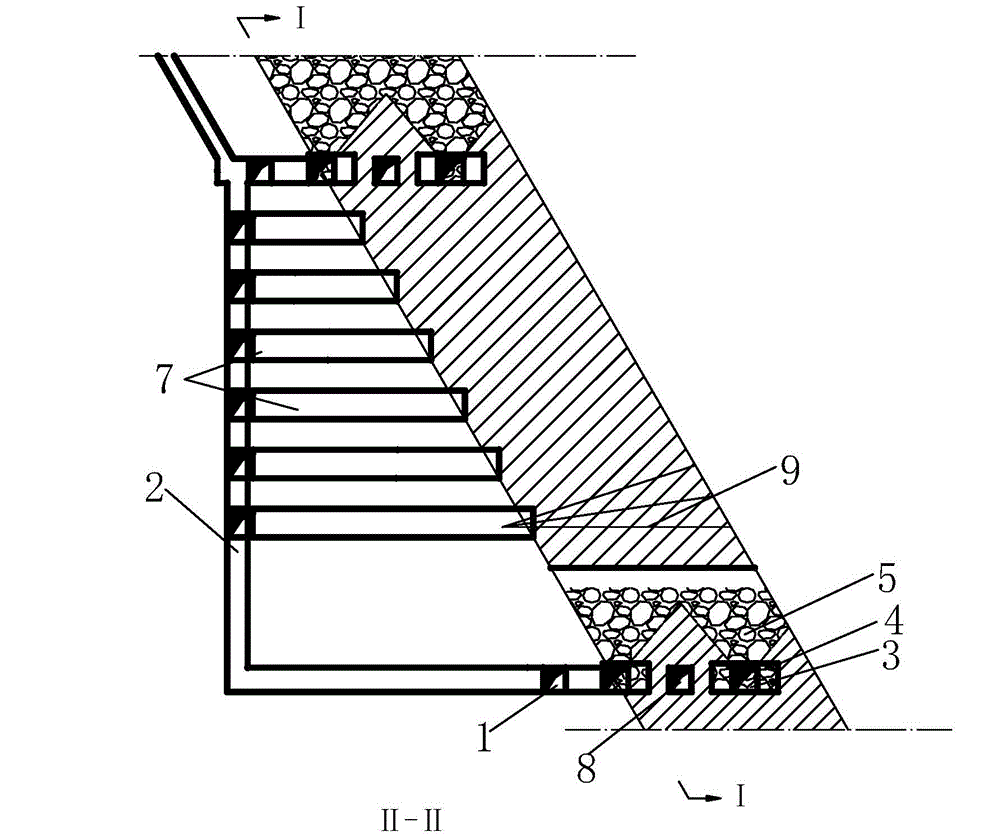

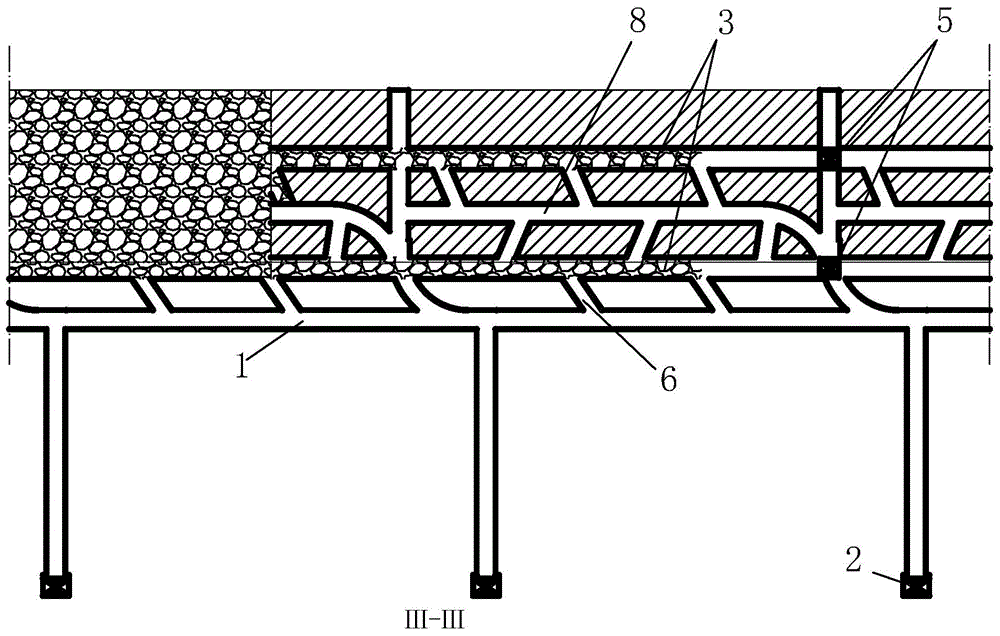

[0026] like figure 1 , figure 2 , image 3 , Figure 4 As shown, the main idea of the mining method with ore retention and caving in the stage of the present invention is that large-area goafs do not occur in the mining process, and the caving ore is used to support the surrounding rock of the upper wall in the early stage of mining, and the upper part of the mining area is withdrawn from the bottom in the later stage of mining. The overlying rock is moved down to fill the goaf to control the ground pressure and achieve safe and efficient mining.

[0027] In terms of specific implementation, a herringbone-shaped trackless ore loading approach 6 with a flat bottom structure is arranged at the bottom of each ore block. A pedestrian ventilation patio 2 is arranged in the central footwall of the ore body, and rock drilling chambers 7 are arra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com