Patents

Literature

43results about How to "Improve rock drilling efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

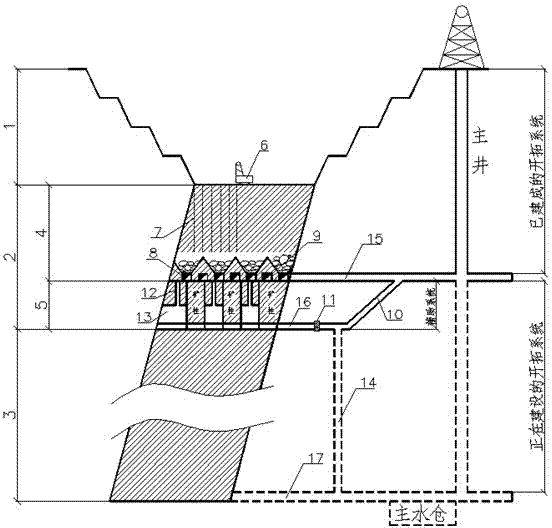

Transition connection mining technique from outdoor mine to underground mine

ActiveCN103790589AImprove rock drilling efficiencyIncrease production capacityUnderground miningSurface miningTransition stagePunching

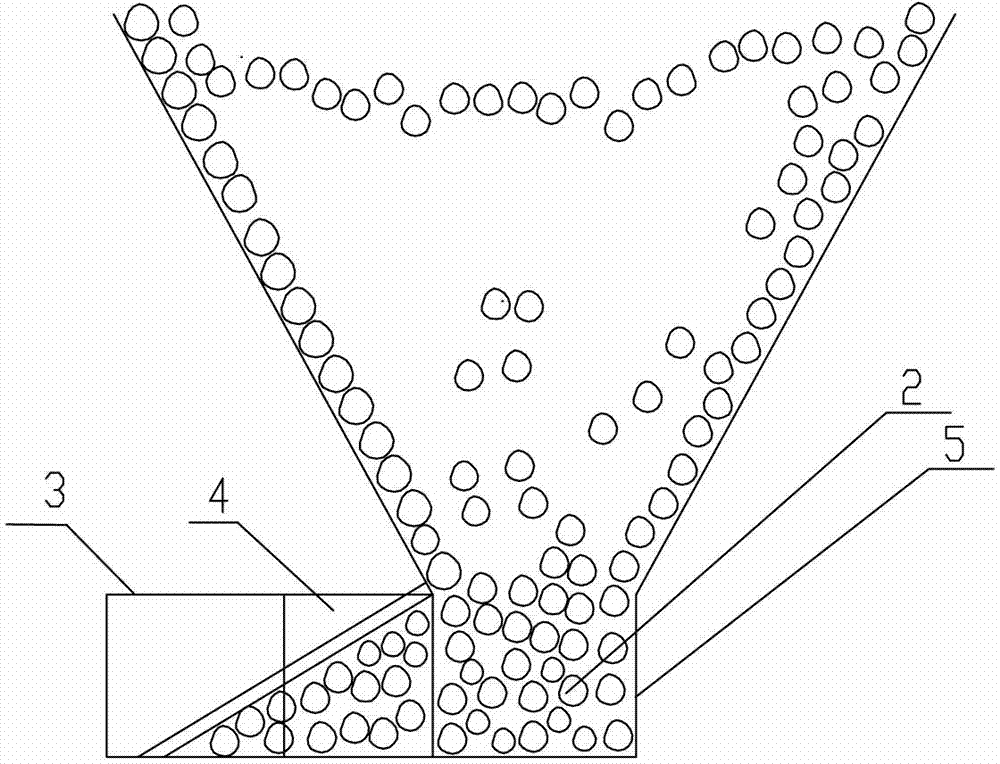

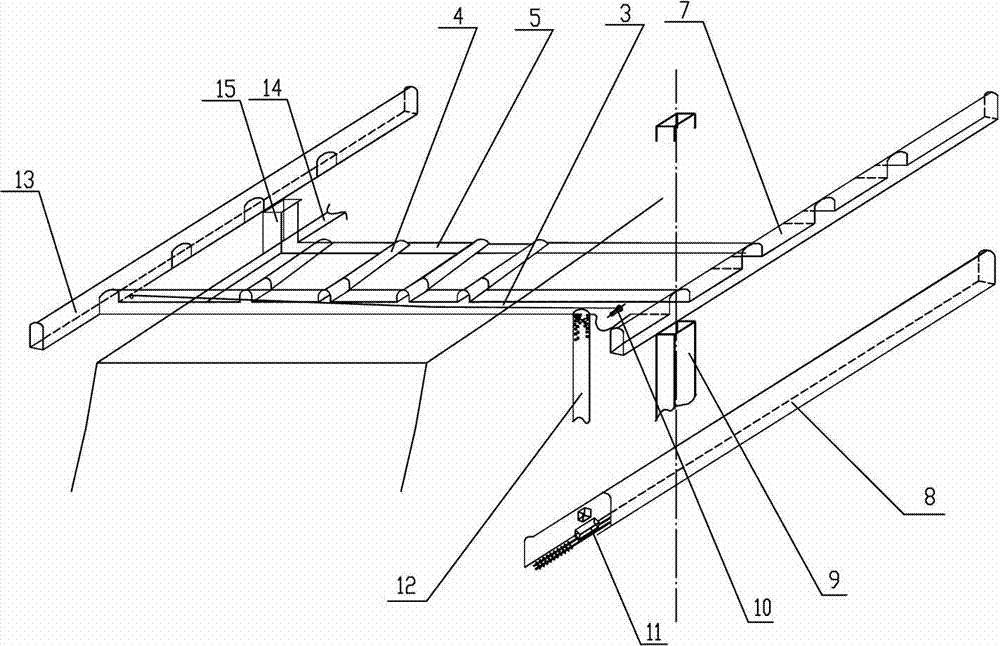

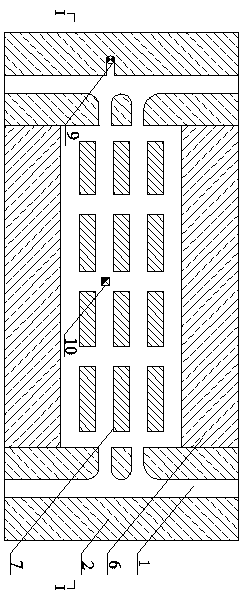

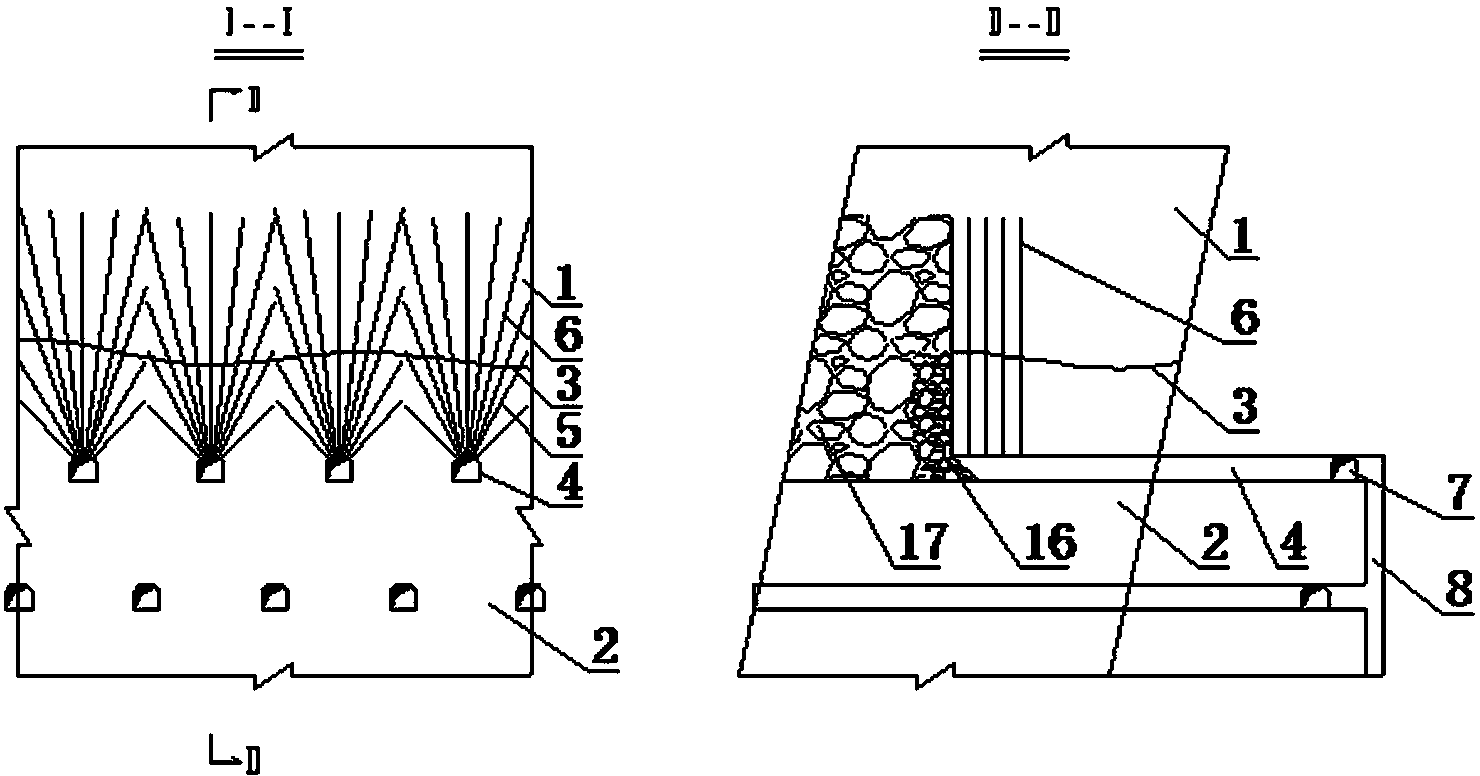

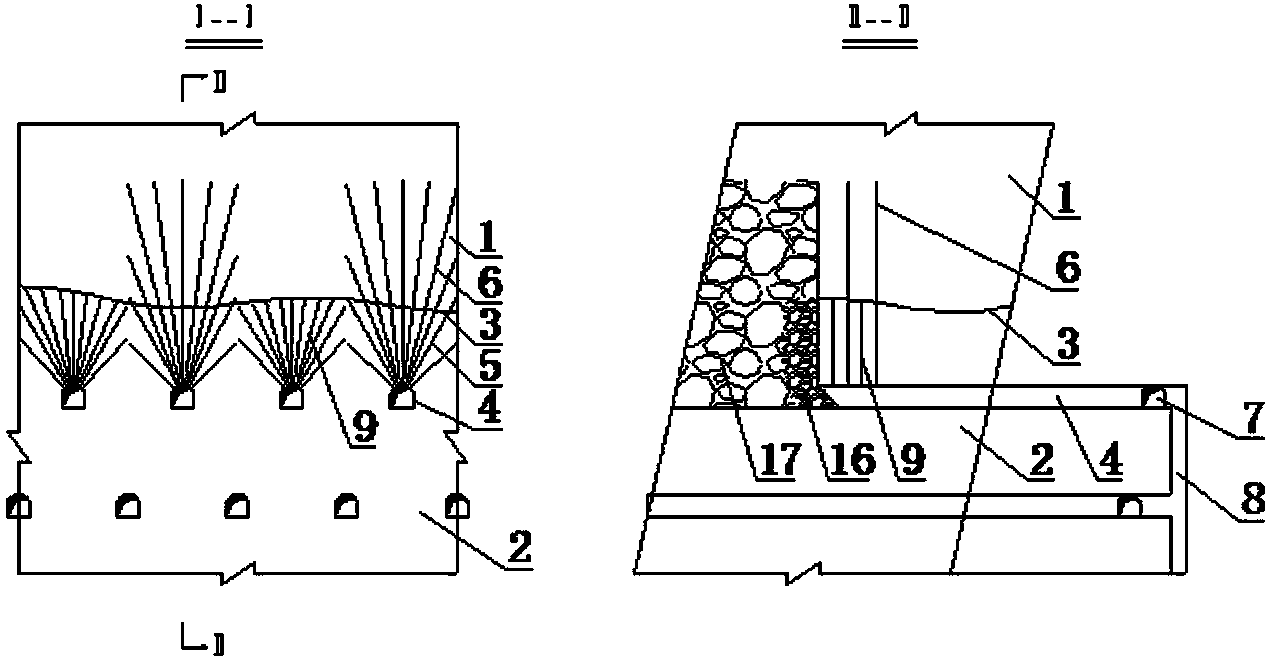

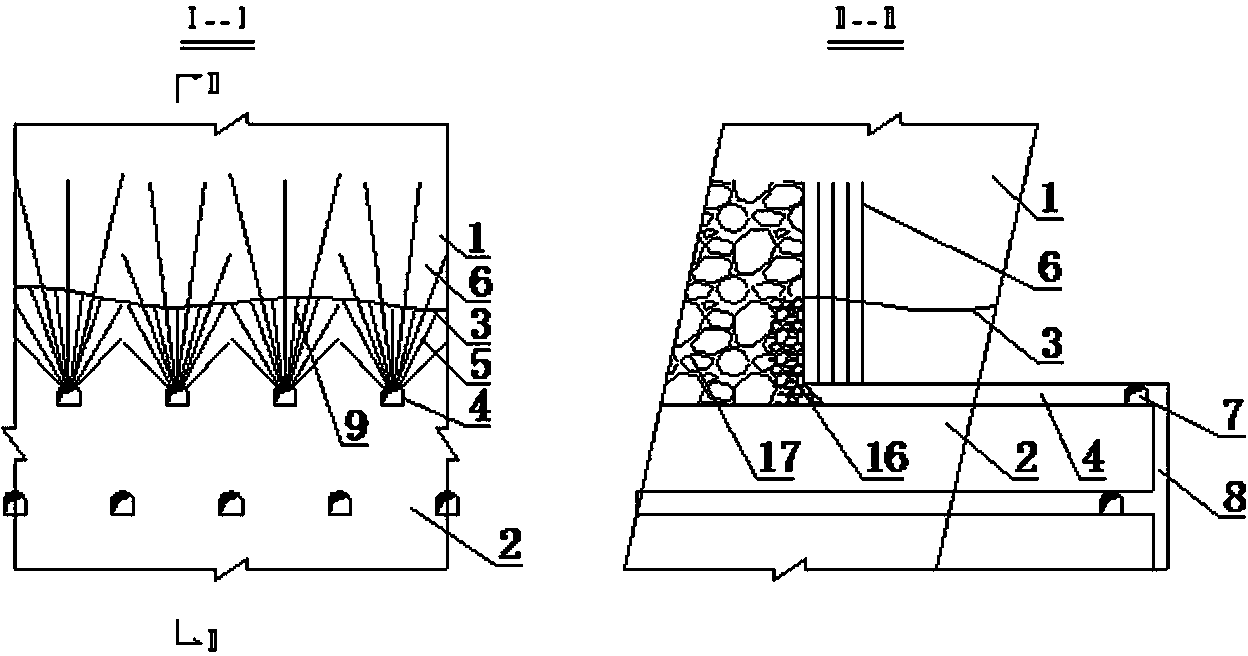

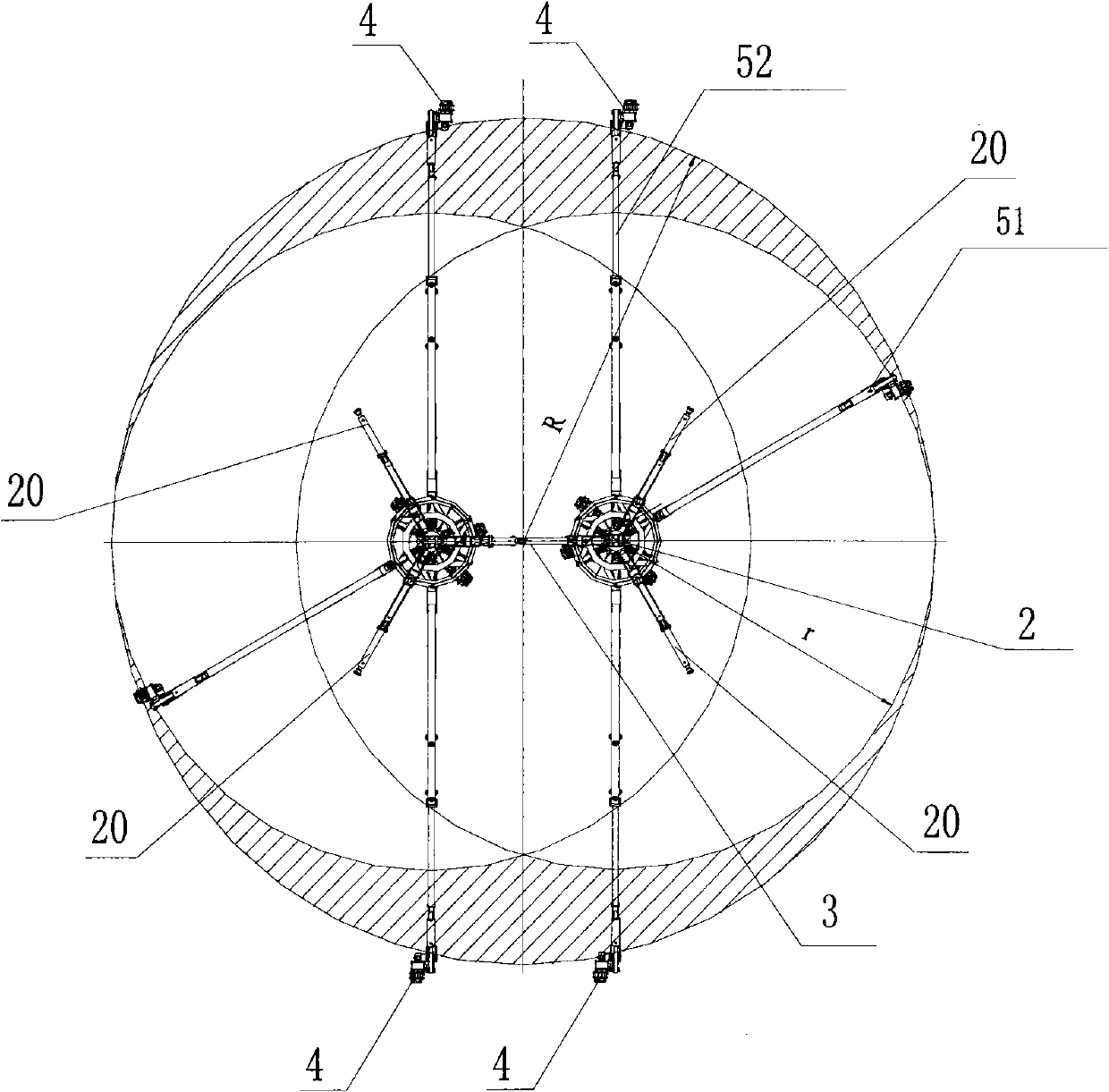

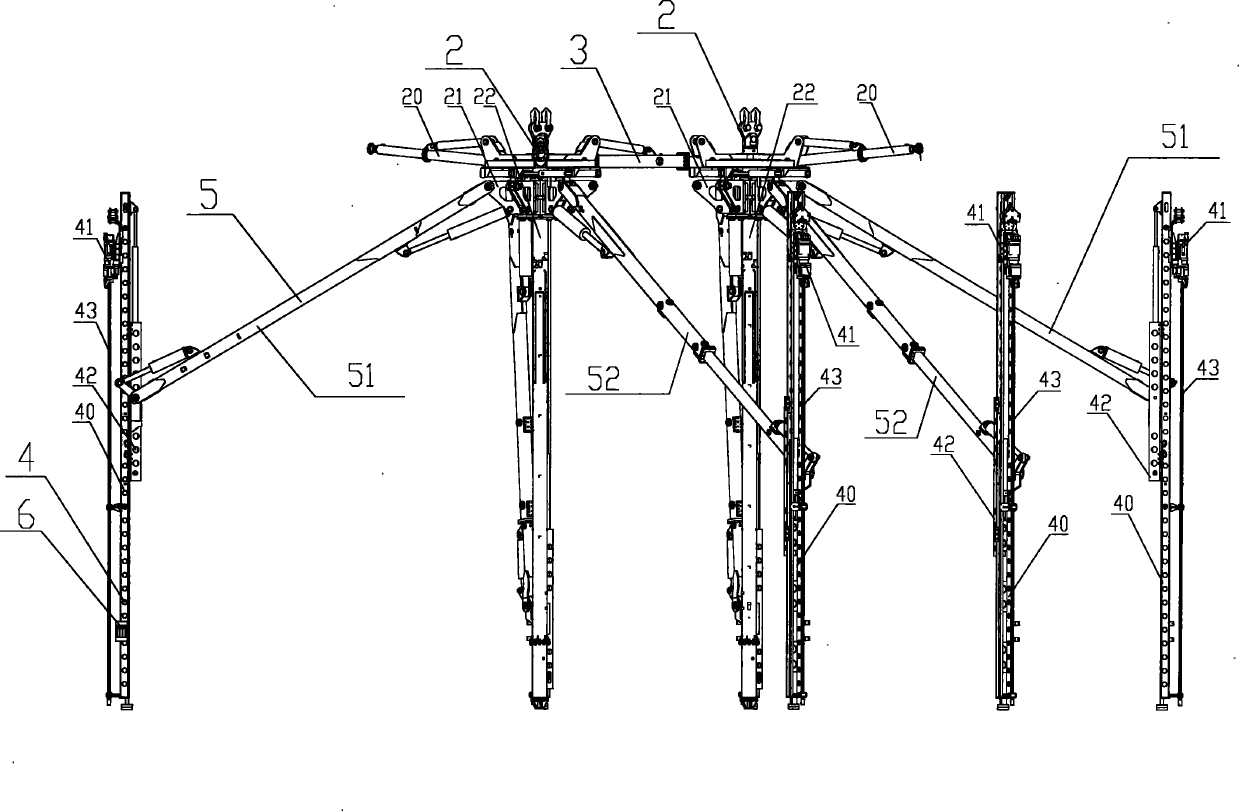

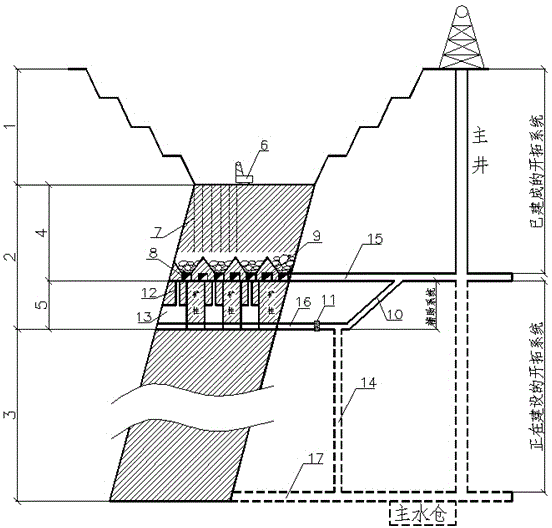

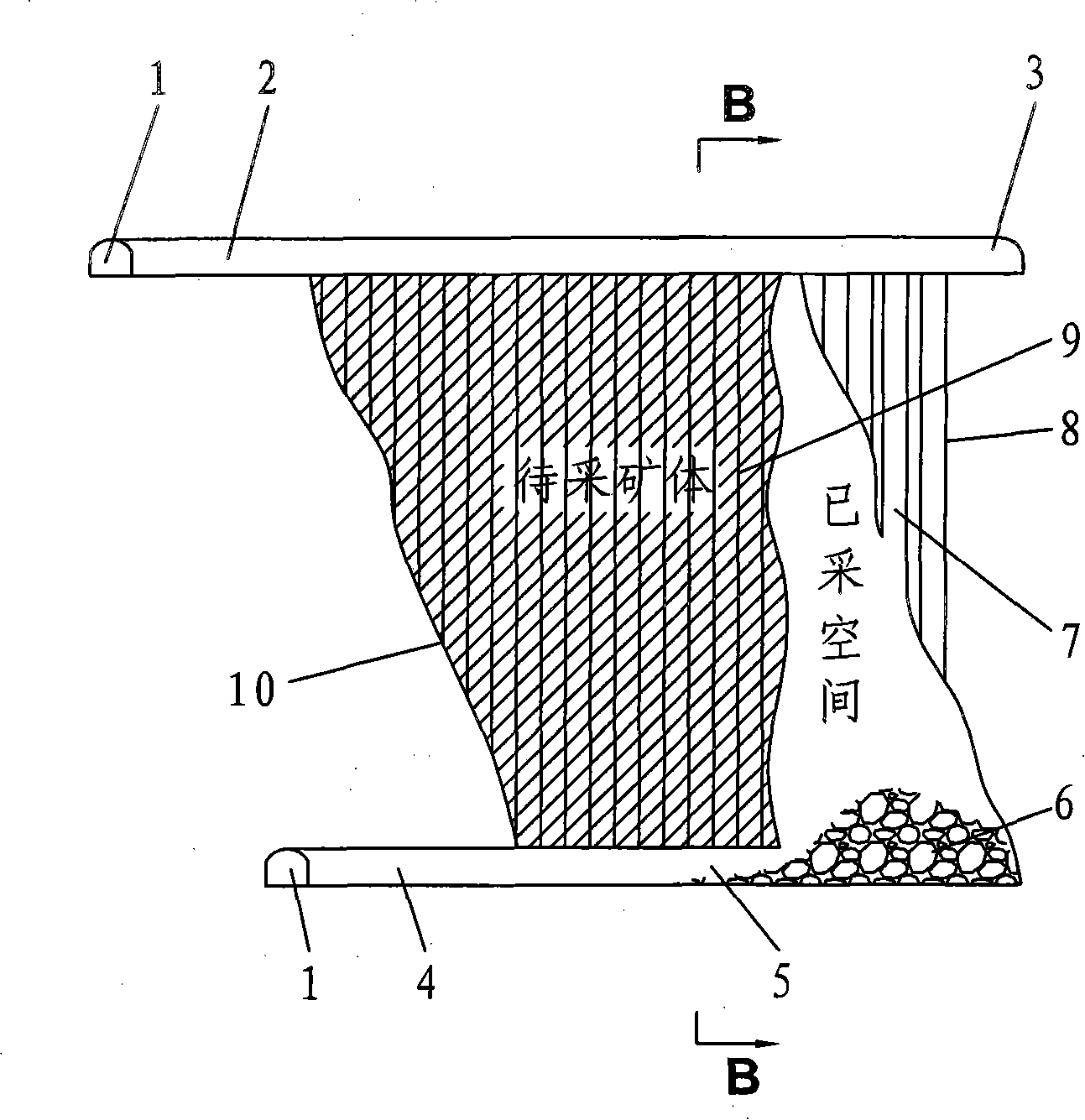

The invention discloses a transition connection mining technique from outdoor mine to underground mine. A transition stage(2) from outdoor mining to underground mining is divided into a connection production middle section (4) and an emergency middle section (5); in the emergency middle section (5), mine chambers (13) and mine columns are divided, and the mine chambers (13) are firstly recovered by utilizing an open-stope method; in the mine chambers (13), upward drainage ventilation holes (12) are dug to be communicated with the connection production middle section (4); an enclosed waterproof door (11) is installed in a development drift (16) in the emergency middle section; a VCR (vertical crater retreat) method is adopted for mining by drilling rocks through an outdoor punching device (6) and discharging ores through an underground bottom structure; a drainage well (14) is drilled between a blind oblique well (10) and the waterproof door (11) and is communicated with the middle section of a main water bin; water accumulated in the mine chambers (13) is pumped and exhausted to the ground surface by a water pump in the main water bin, and the mine columns are recovered; then the underground mining stage (3) is transited. According to the invention, the safe and stable transition from outdoor mining to underground mining is realized, and the problems of underground sudden inflow of water threat, great damage of the preserved mine columns and difficulty in recycling at the rear stage are solved.

Owner:SINOSTEEL MAANSHAN INST OF MINING RES

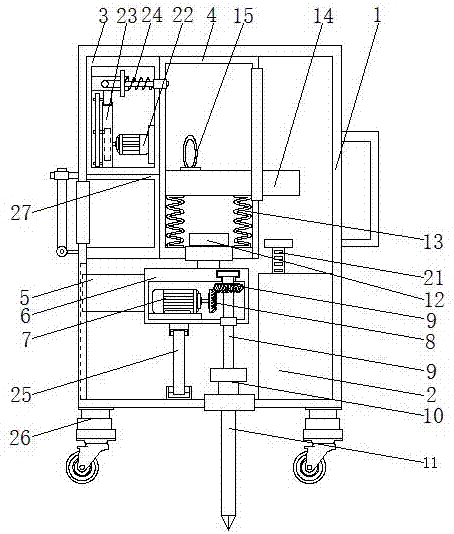

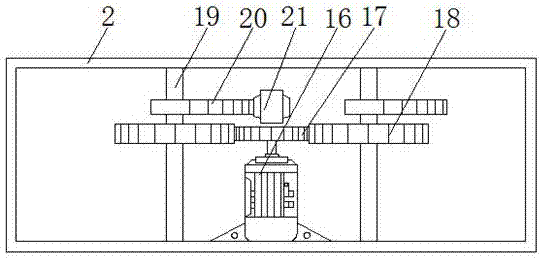

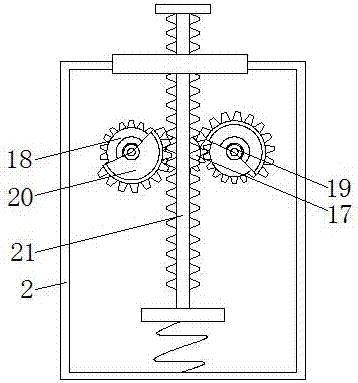

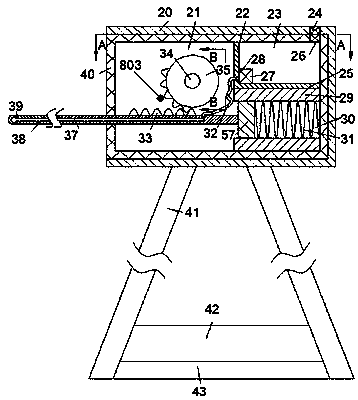

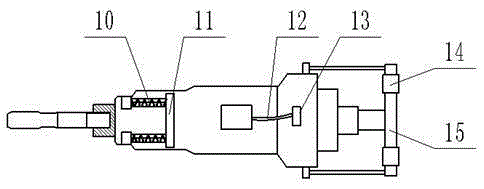

Simple and convenient rock drilling machine

InactiveCN107100543ASimple and convenient rock drillingReduce volumeConstructionsRotary drillingDrilling machinesDrill bit

The invention discloses a simple and convenient rock drilling machine, and belongs to the technical field of rock drilling machines. The simple and convenient rock drilling machine comprises a box body, a bottom box is fixedly connected to the right side of the bottom of the inner wall of the box body, a top box and a movable box are fixedly connected to the top of the inner wall of the box body sequentially from left to right, and a connecting block is slidably connected to the left side of the inner wall of the box body; a motor box is fixedly connected to the side, far away from the inner wall of the box body, of the connecting block, a first motor is fixedly connected to the bottom of the inner wall of the motor box, and a first tapered gear is fixedly connected to the output shaft of the first motor; and a second tapered gear is engaged with one side of the first tapered gear. The simple and convenient rock drilling machine can conduct rock drilling conveniently, so that the size of the device is greatly reduced, and unnecessary wastes are reduced. Pressure can be increased simultaneously when a drilling bit drills a rock, the rock drilling efficiency is improved greatly, the time consumption is reduced, the burdens of operation workers can be relieved, and the operation is very convenient.

Owner:HUNAN UNIV OF ARTS & SCI

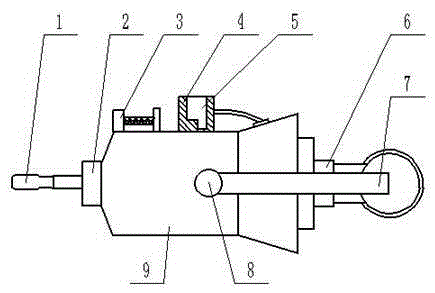

Multi-angle adjustable rock drilling equipment

ActiveCN107152239AImprove work efficiencySpeed upDerricks/mastsBorehole drivesEngineeringCircular disc

The invention discloses multi-angle adjustable rock drilling equipment, comprising a base; the top of the base is fixedly connected with a support block; the support block is internally and rotatably connected with a rotary rod; the surface of the rotary rod is respectively and fixedly connected with a limiting block and a rotating device; a power device is fixedly connected with one side of the rotating device; the rotating device comprises a first motor and a stable block; the bottoms of the first motor and the stable block are respectively and fixedly connected with the surface of the rotary rod; an output shaft of the first motor is fixedly connected with a disc by means of a coupling; the front of the disc is fixedly connected with a sliding rod; the multi-angle adjustable rock drilling equipment relates to the technical field of rock drilling. The multi-angle adjustable rock drilling equipment solves the problem that different-angle rock drilling operations need to be performed since rock mass structures are different in a rock drilling process, and the traditional rock drilling machine can not directly convert the angle for drilling rocks, greatly increases the working efficiency, and accelerates rock drilling progress, thus increasing the benefit of an enterprise.

Owner:四川钻神智能机械制造有限公司

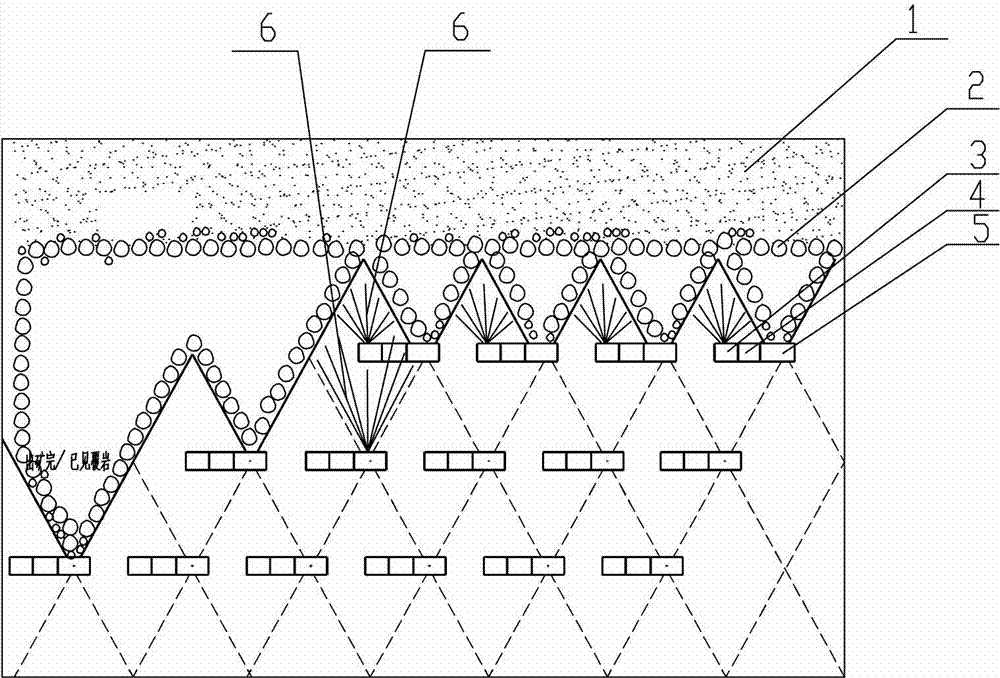

Non-pillar sublevel caving mining method for discharging ores from side part of electric rake roadway

ActiveCN103670417AWith ventilation functionWith escape functionUnderground miningSurface miningSpelunkingEngineering

The invention relates to a non-pillar sublevel caving mining method for discharging ores from a side part of an electric rake roadway. The method comprises the following steps: dividing an ore body into phases, and dividing each phase into segments; arranging segmented accesses in a rhombic staggered manner; excavating a way shaft and an ore chute from a foot-wall phase haulage way to an upper phase foot-wall haulage way along one end of an ore block; then, initially excavating a segmented connection roadway in a first segment of the current phase. The method is characterized in that the rhombic staggered arrangement refers to an arrangement manner of recovering accesses among segments; after the excavation of recovering accesses of the current segment is completed, an electric rake roadway is excavated between the two recovering accesses of the segment and parallel to the recovering accesses; ore crosscuts are excavated at certain intervals between the recovering accesses and the electric rake roadway; a hanging-wall exhausting roadway communicated with the electric rake roadway is excavated from the inner end of the electric rake roadway to the outer side of a mineral vein. Compared with the traditional non-pillar sublevel caving mining method, the non-pillar sublevel caving mining method, provided by the invention, has the advantages of high safety, low cost, good blasting effect, and high rock-drilling efficiency.

Owner:ANSTEEL GRP MINING CO LTD

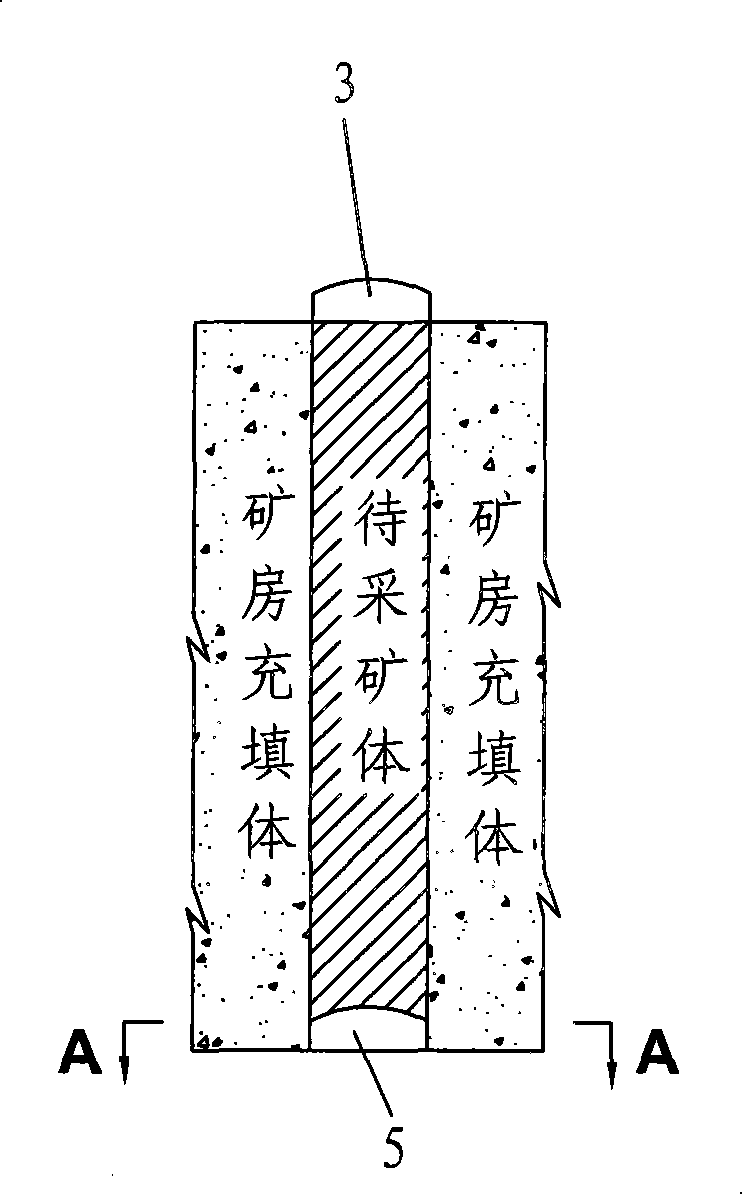

Super-large-scale stope large-diameter deep-hole high-stage open stope subsequent filling mining method and application

InactiveCN109989754AImprove rock drilling efficiencyLarge amount of mining and cuttingUnderground miningSurface miningStopingMaterials science

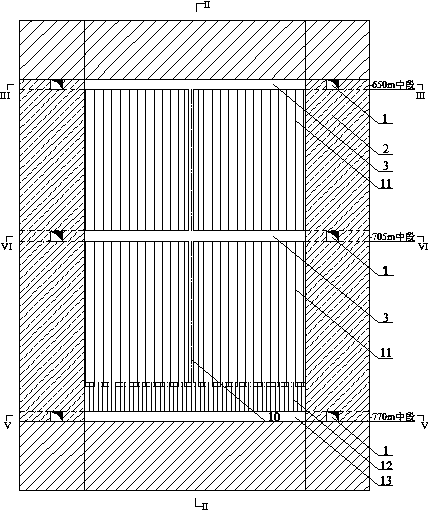

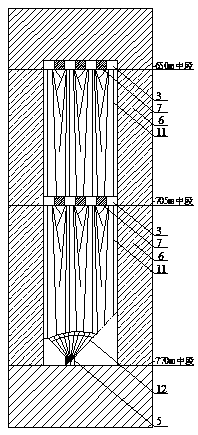

The invention discloses a super-large-scale stope large-diameter deep-hole high-stage open stope subsequent filling mining method and application. The method comprises the following steps: (1) a stoping scheme: ore blocks are arranged perpendicular to the trend of an ore body, the ore blocks are divided into ore chambers and ore columns, the ore chambers and the ore columns are arranged at intervals, a stope is divided into two middle sections by adopting double-middle-section continuous stoping, and a stoping method of middle-section rock drilling, double-middle-section continuous ore breaking ground, bottom ore removal structure sharing and subsequent first filling is adopted; (2) stope preparations; (3) courtyard cutting; (4) rock drilling and blasting; (5) ore removal; and (6) filling.The method has the beneficial effects that the super-large-scale stope has the advantages of being small in stope cutting work amount, large in stope ore quantity and the like; the stope is divided into two middle sections for rock drilling, the technical difficulty of deep-hole rock drilling of the stope is reduced, and the rock drilling efficiency of the stope is improved; the double-middle-section continuous ore breaking ground is adopted, and the bottom ore removal structure is shared, and the method has the advantages that the production capacity of a single stope is improved, the miningand cutting cost is reduced, the stoping efficiency is improved, and the like.

Owner:ANHUI TONGGUAN (LUJIANG) MINING CO LTD

Method for forming covering layer by stope caving method

The invention discloses a method for forming a covering layer by a stope caving method. During the first sublevel stoping under top wall rock, a rock drilling roadway required by the first sublevel stoping is used for drilling an upward fan-shaped medium-depth hole; the stoped upward fan-shaped blast hole is drilled to an ultra-deep state into the top wall rock; the blast hole is totally filled with explosives in the full length; the full length of the blast hole is blasted in one step; the first sublevel ore and the upper top wall rock are simultaneously blasted into fragments; and after the blasting, ores are positioned at the lower part, and waste stones are positioned at the upper part. When the method provided by the invention is used, the new tunneling caving engineering is not needed; the cost and the time are reduced; the yield of a stoping field is favorably improved; the installing time of a newly drilled blast hole drilling machine is reduced; the integral rock drilling efficiency is improved; and blocky structures of the waste stones are favorable for ground pressure management and depletion loss reduction.

Owner:CHINA MINMETALS CHANGSHA MINING RES INST

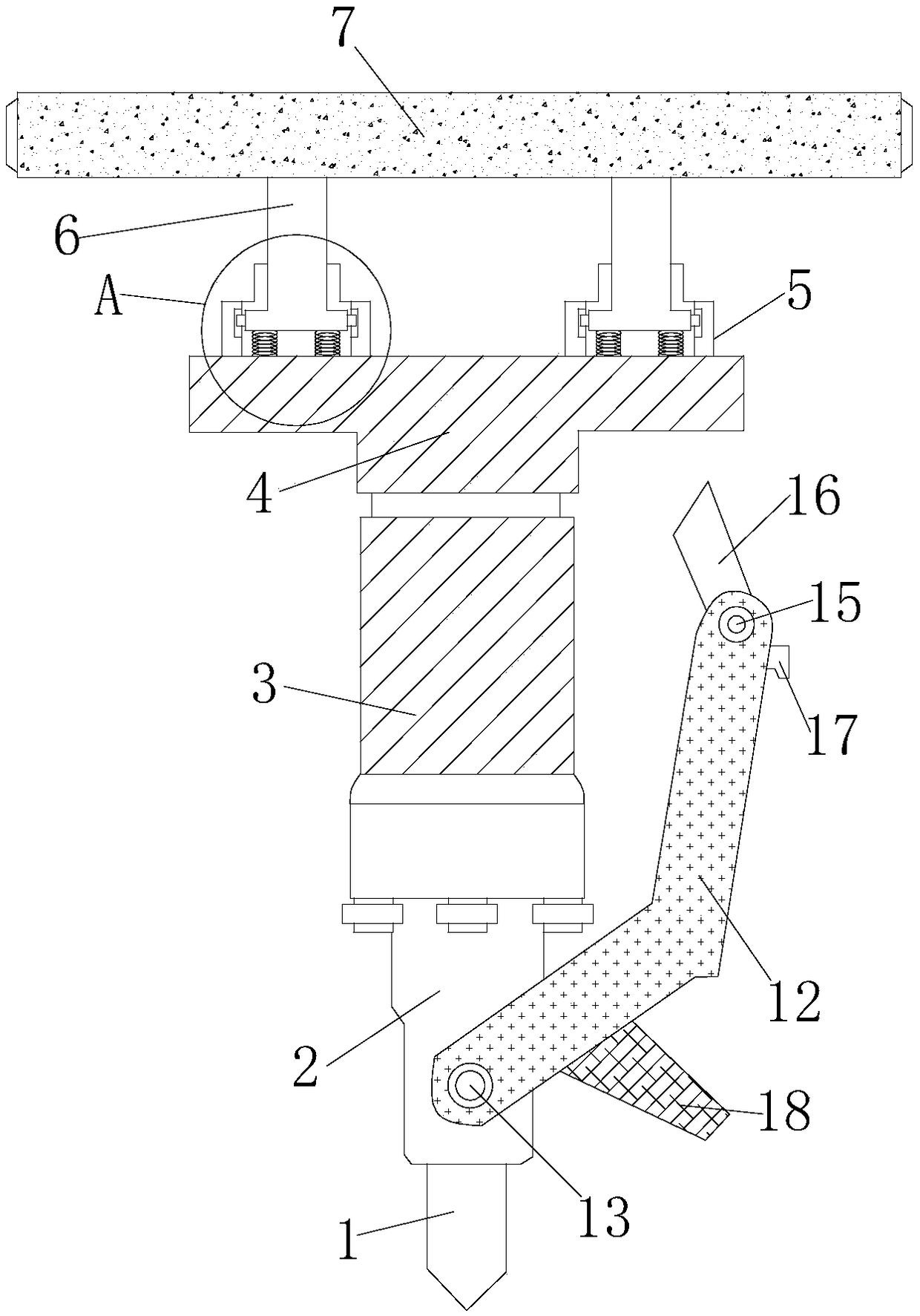

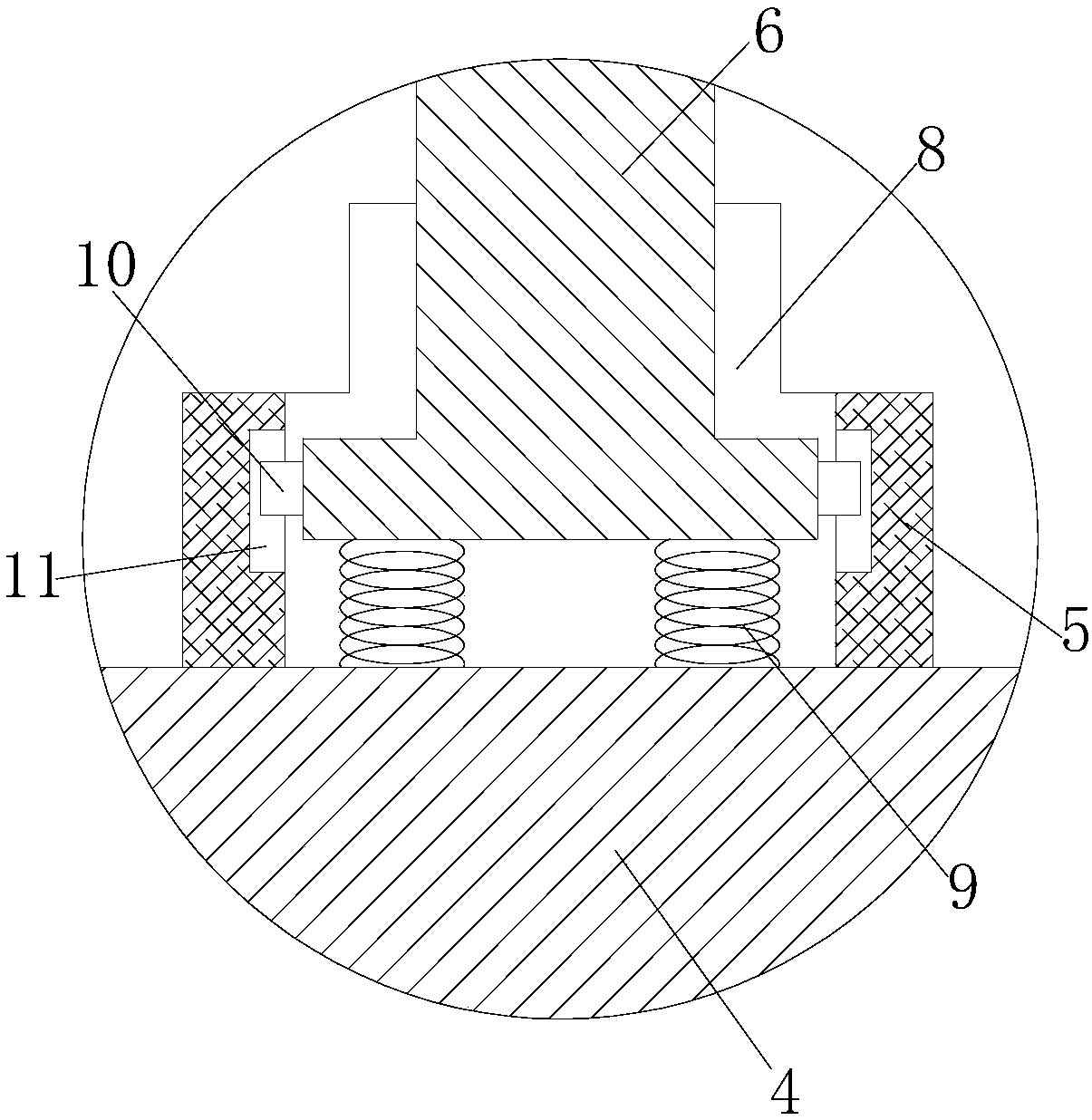

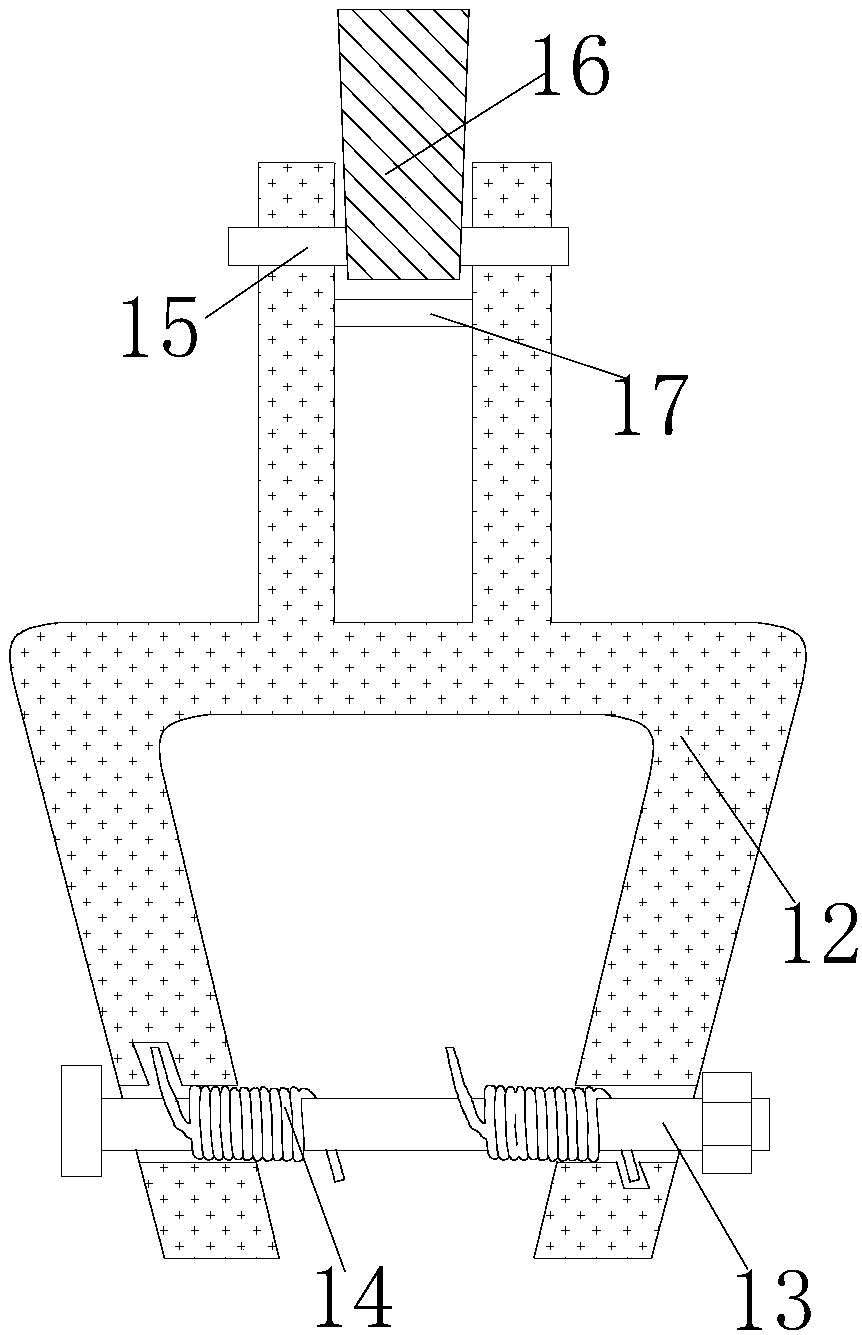

Hand-held rock drill

The invention discloses a hand-held rock drill which comprises a drill tool; a rock drill head is arranged at the top end of the drill tool; a rock drill main body is arranged at the top end of the rock drill head; a handle body is arranged at the top end of the rock drill main body; fixing seats are arranged on the two sides of the top end of the handle body respectively and are internally provided with clamping grooves respectively; a clamping column is connected to the interior of each clamping groove in a clamping manner; sliding blocks are arranged on the two sides of the lower part of each clamping column respectively and are arranged in limiting grooves formed in the inner wall of each clamping groove respectively; springs are arranged on the two sides of the bottom end of each clamping column respectively; a handle is arranged at the top ends of the two clamping columns; and a connection frame is arranged on the outer wall of the rock drill head and is rotationally connected with the rock drill head through a first rotation pin. By adopting the hand-held rock drill provided by the invention, vibration generated when the rock drill works can be well absorbed through the springs arranged on the two sides of the bottom ends of each clamping column respectively; and in addition, the sliding blocks on the two sides of the lower part of each clamping column can realize movement in a small range in the corresponding limiting grooves, so that people feel more comfortable when using the rock drill to work.

Owner:天津市九方煤矿机械制造有限公司

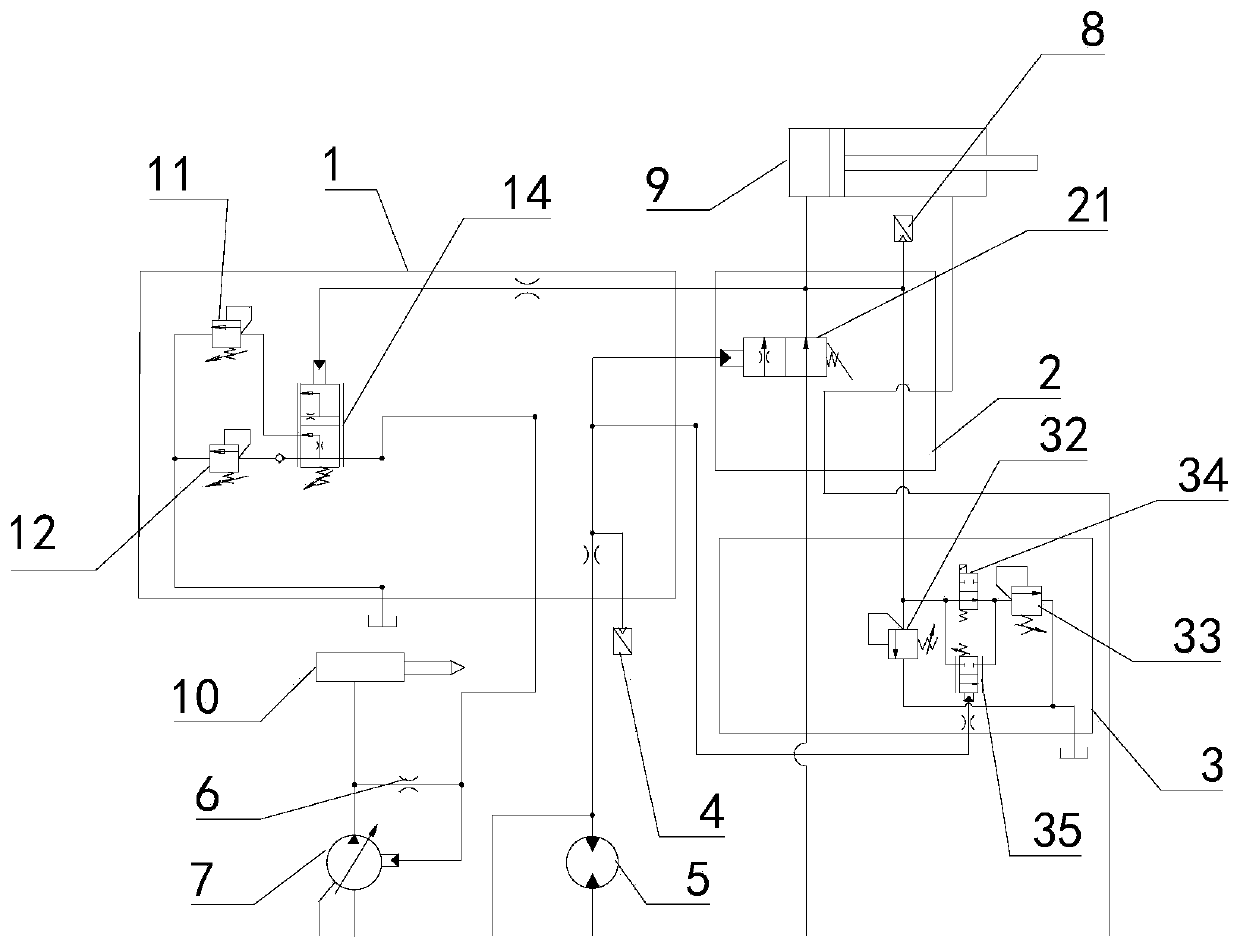

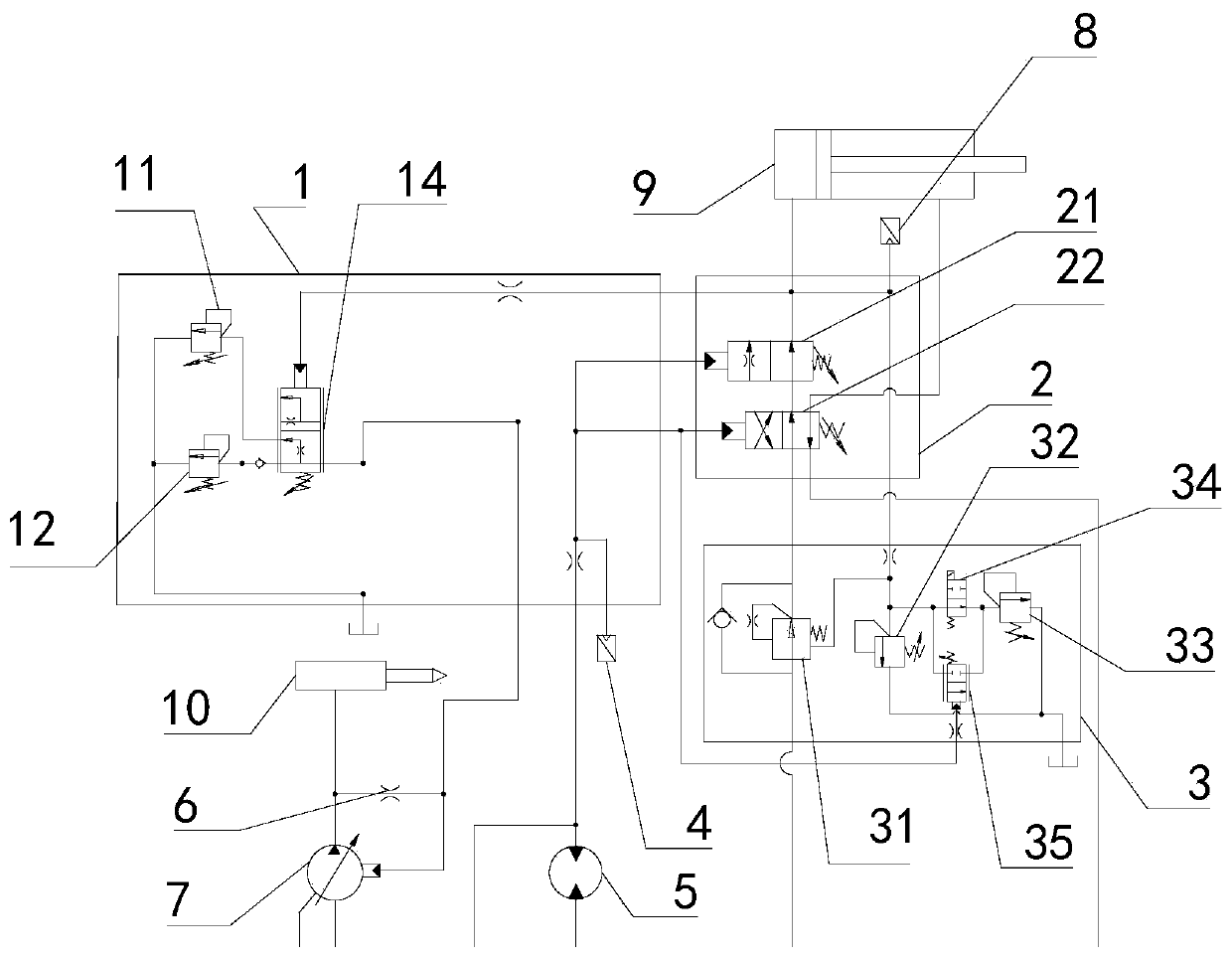

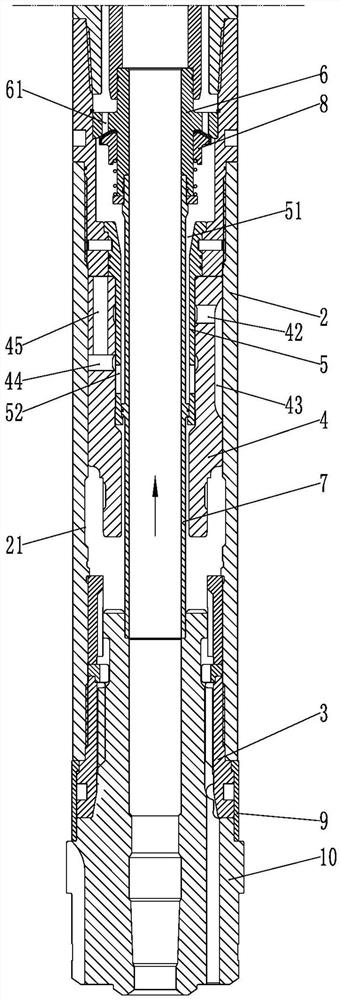

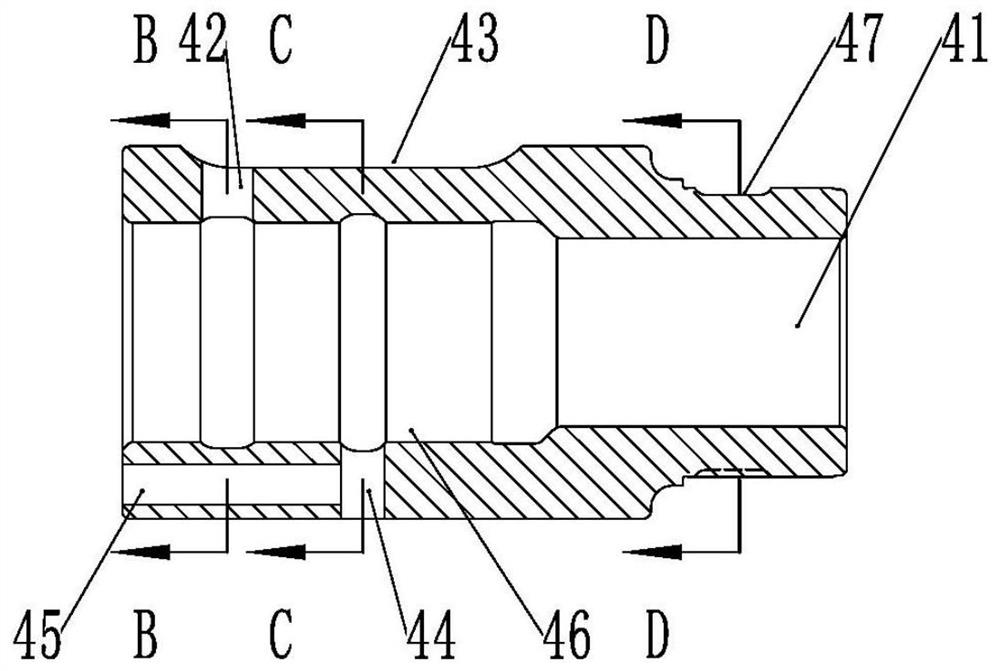

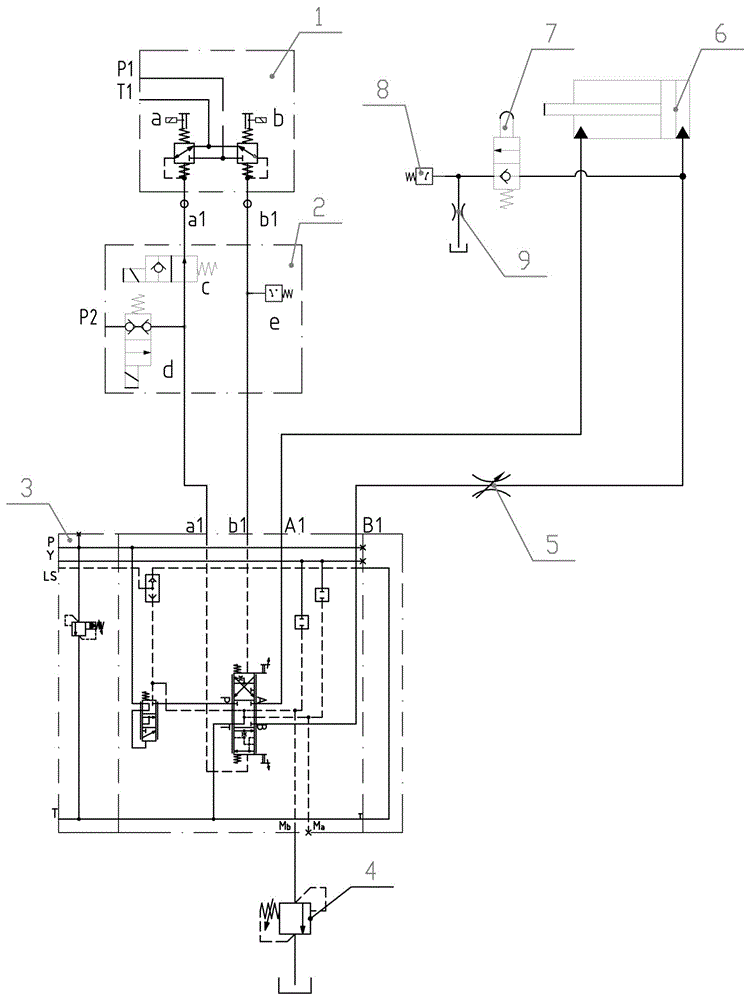

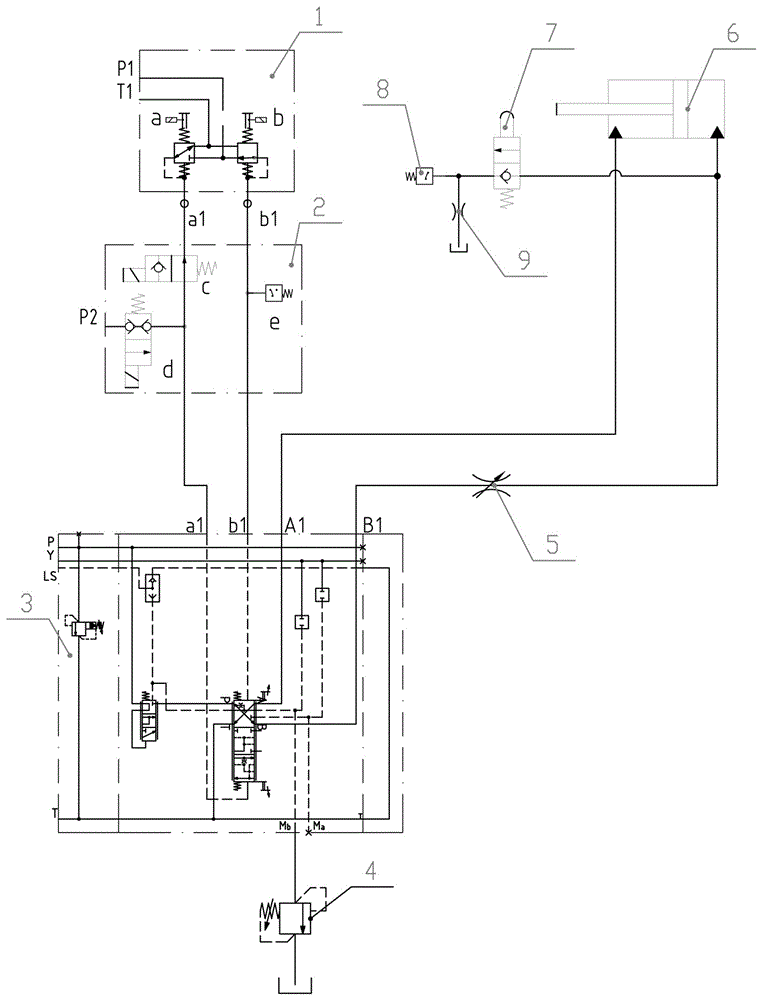

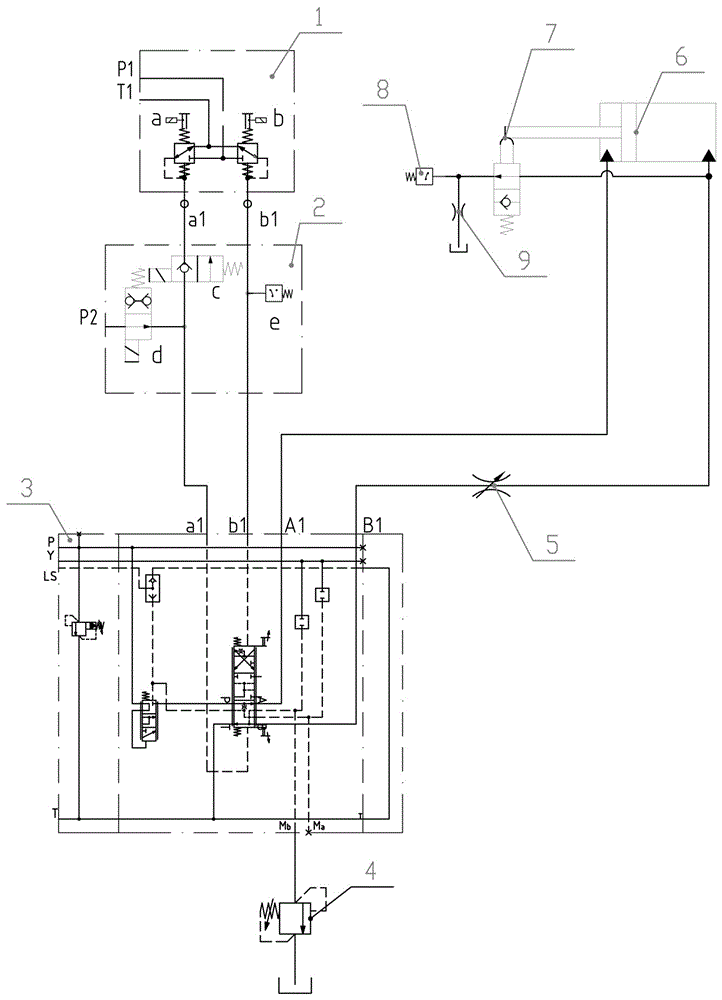

Anti-borer-clamping hydraulic control system and rock drilling equipment

PendingCN110242628AAchieve stabilityAvoid stuck pipe accidentsServomotor componentsServomotorsFuel tankAdaptive matching

The invention relates to the technical field of rock drilling equipment, in particular to an anti-borer-clamping hydraulic control system and rock drilling equipment. The anti-borer-clamping hydraulic control system comprises an impact control module, a propelling pressure control module, a propelling speed control module, a variable pump, a rotation motor and a propelling oil cylinder; the impact control module comprises a first proportion reversing valve communicated with a load feedback port of the variable pump and an oil tank, and a guide control port of the first proportion reversing valve is connected with an oil inlet of the propelling oil cylinder; the propelling pressure control module comprises a third proportion reversing valve communicated with the air inlet of the propelling oil cylinder and the oil tank; the propelling speed control module comprises a guide proportion throttling valve connected between the oil tank and the oil inlet of the propelling oil cylinder, and guide control ports of the third proportion reversing valve and the guide proportion throttling valve are connected with an oil inlet of the rotation motor. The rock drilling equipment comprises the anti-borer-clamping hydraulic control system. The anti-borer-clamping hydraulic control system and the rock drilling equipment are in self-adaption with various rock strata and are matched with reasonable impact pressure, propelling pressure and propelling speed.

Owner:HUNAN WUXIN TUNNEL INTELLIGENT EQUIP CO LTD

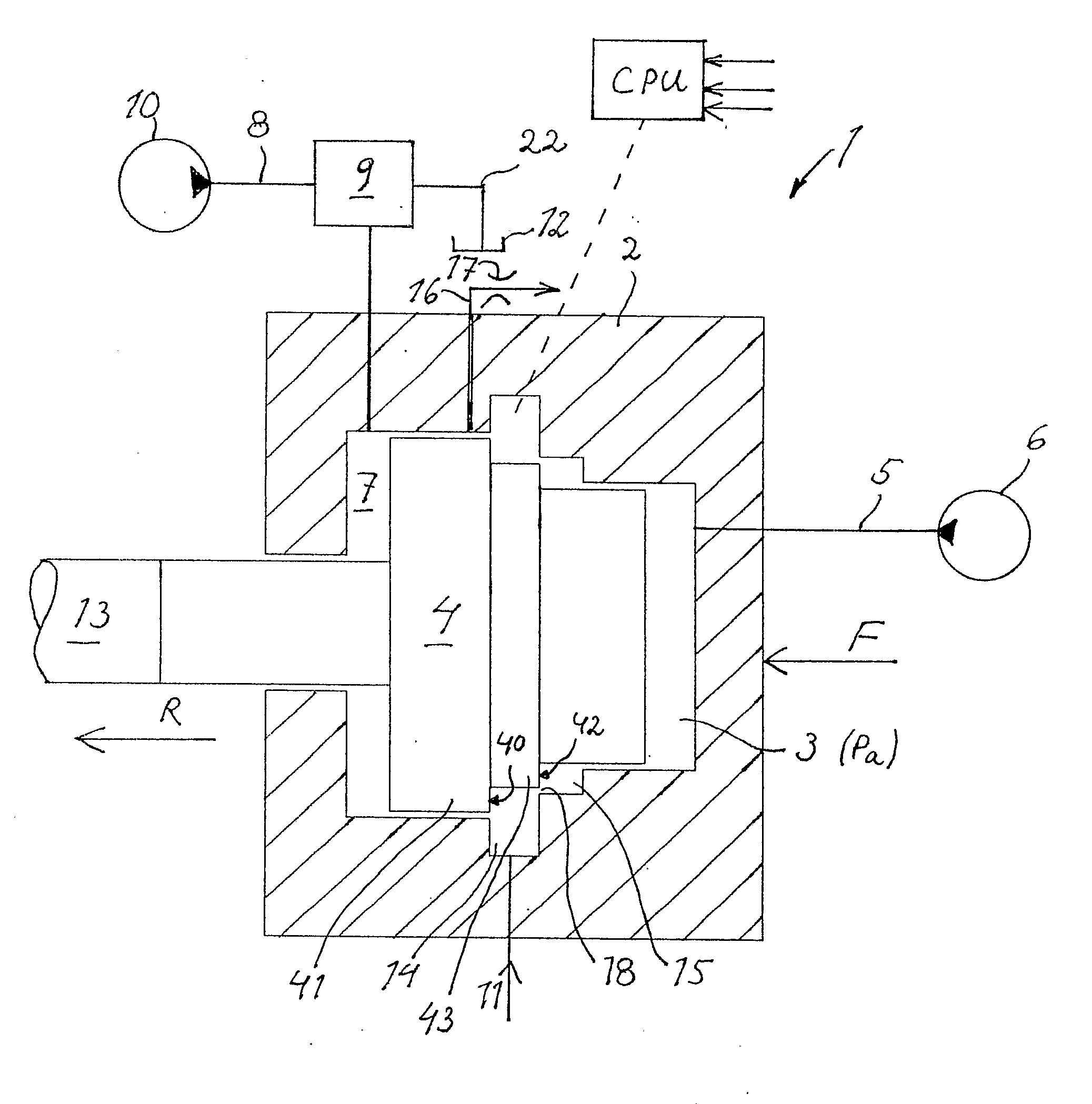

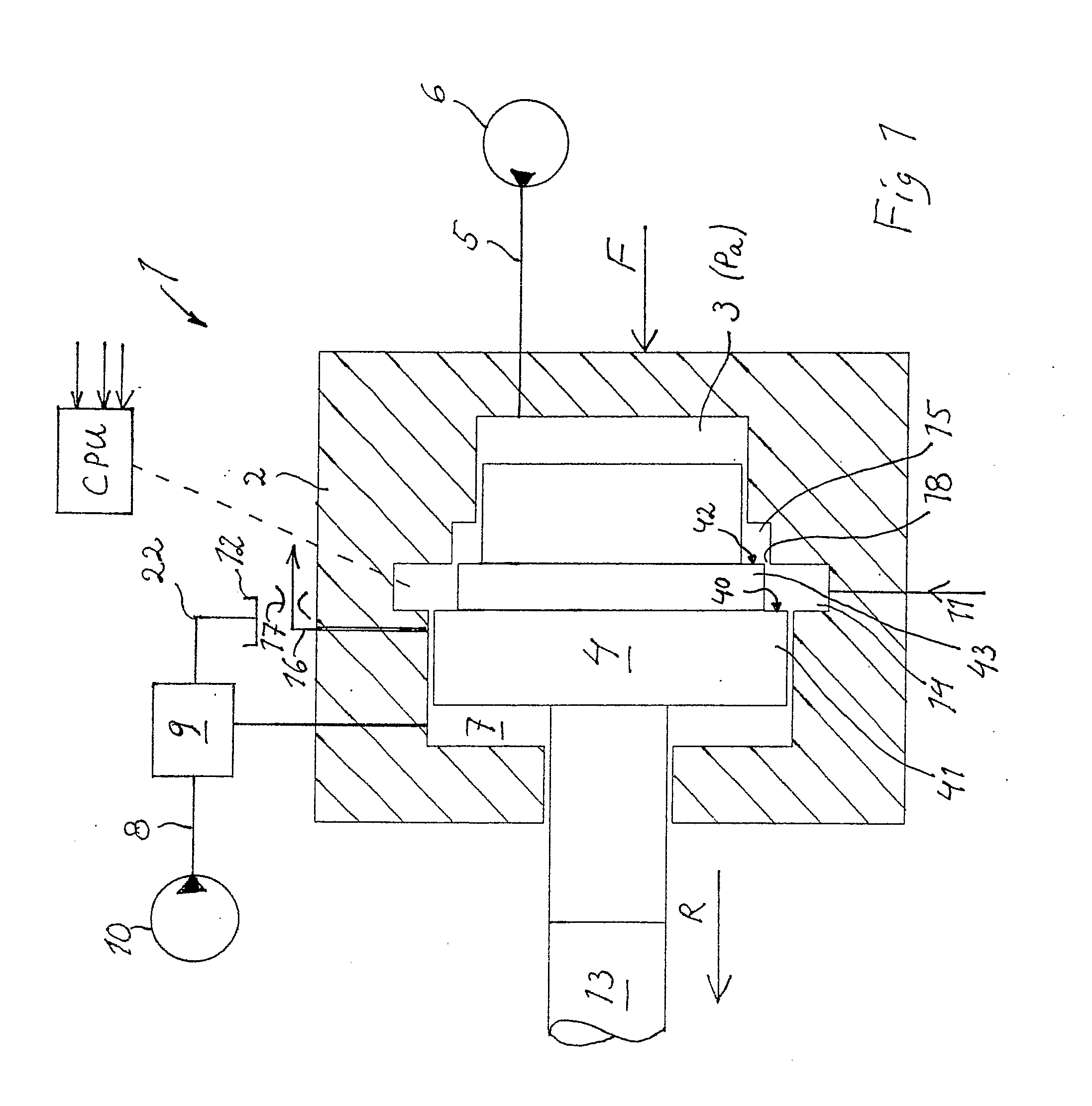

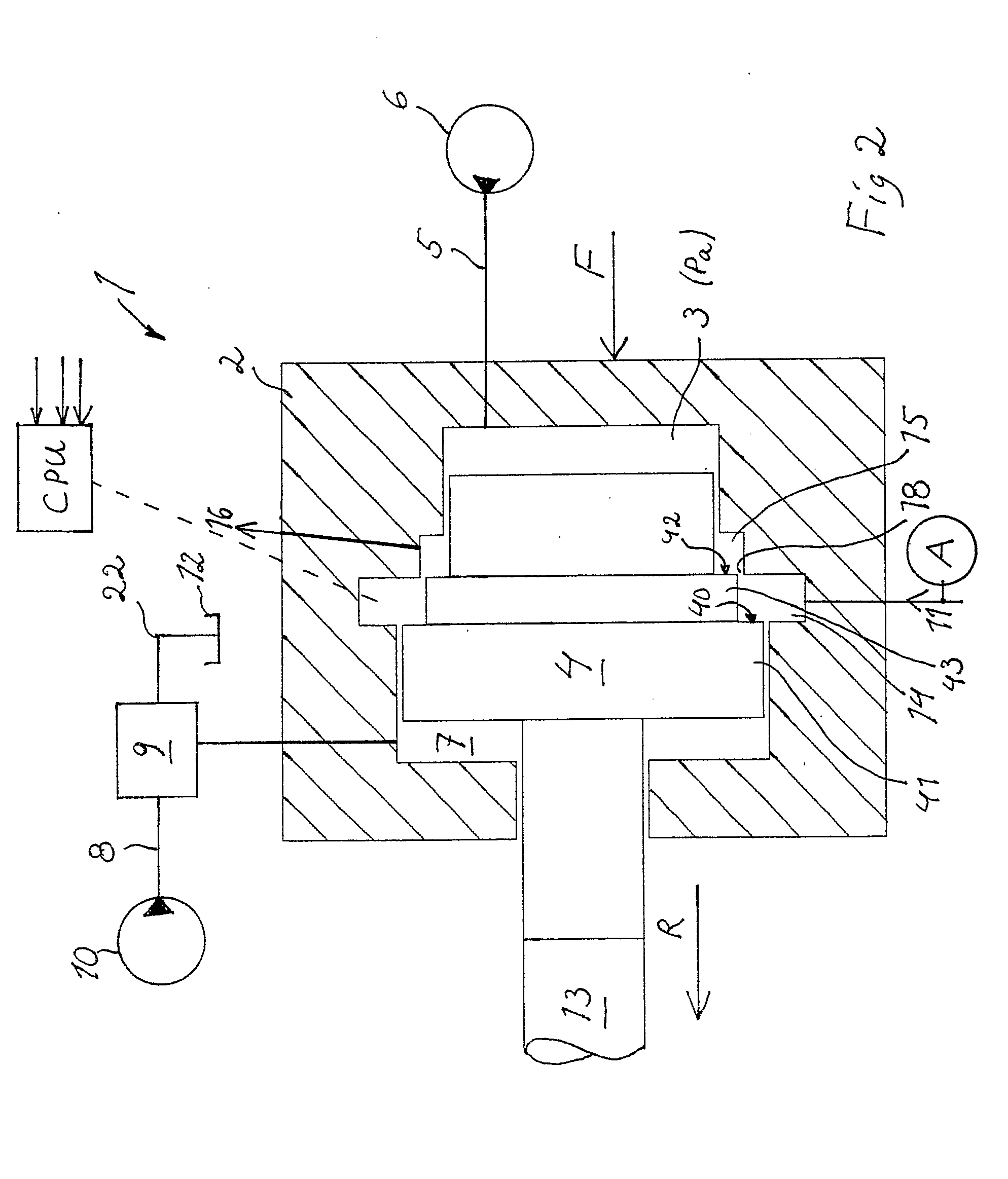

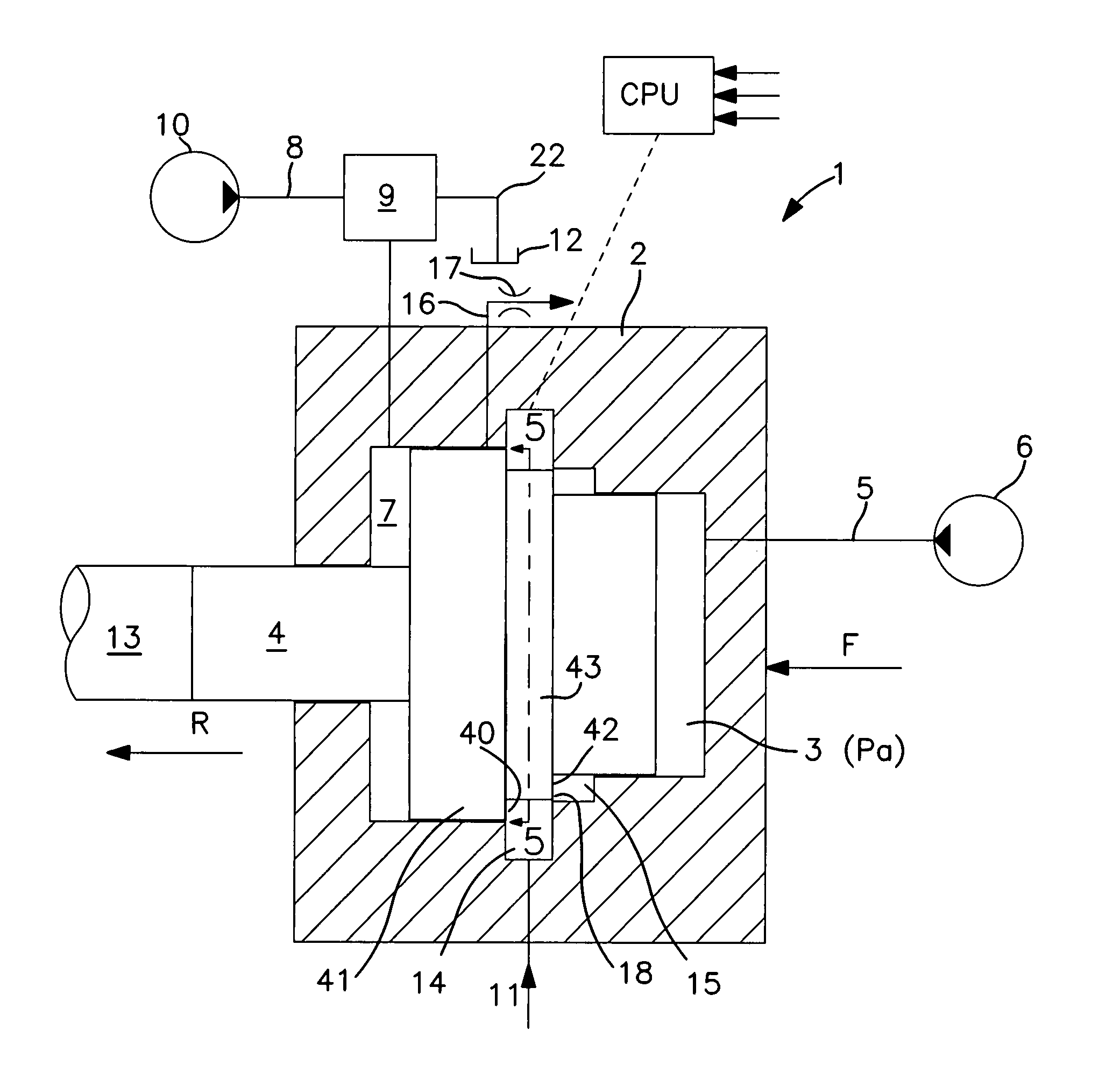

Rock drilling method and rock drilling machine

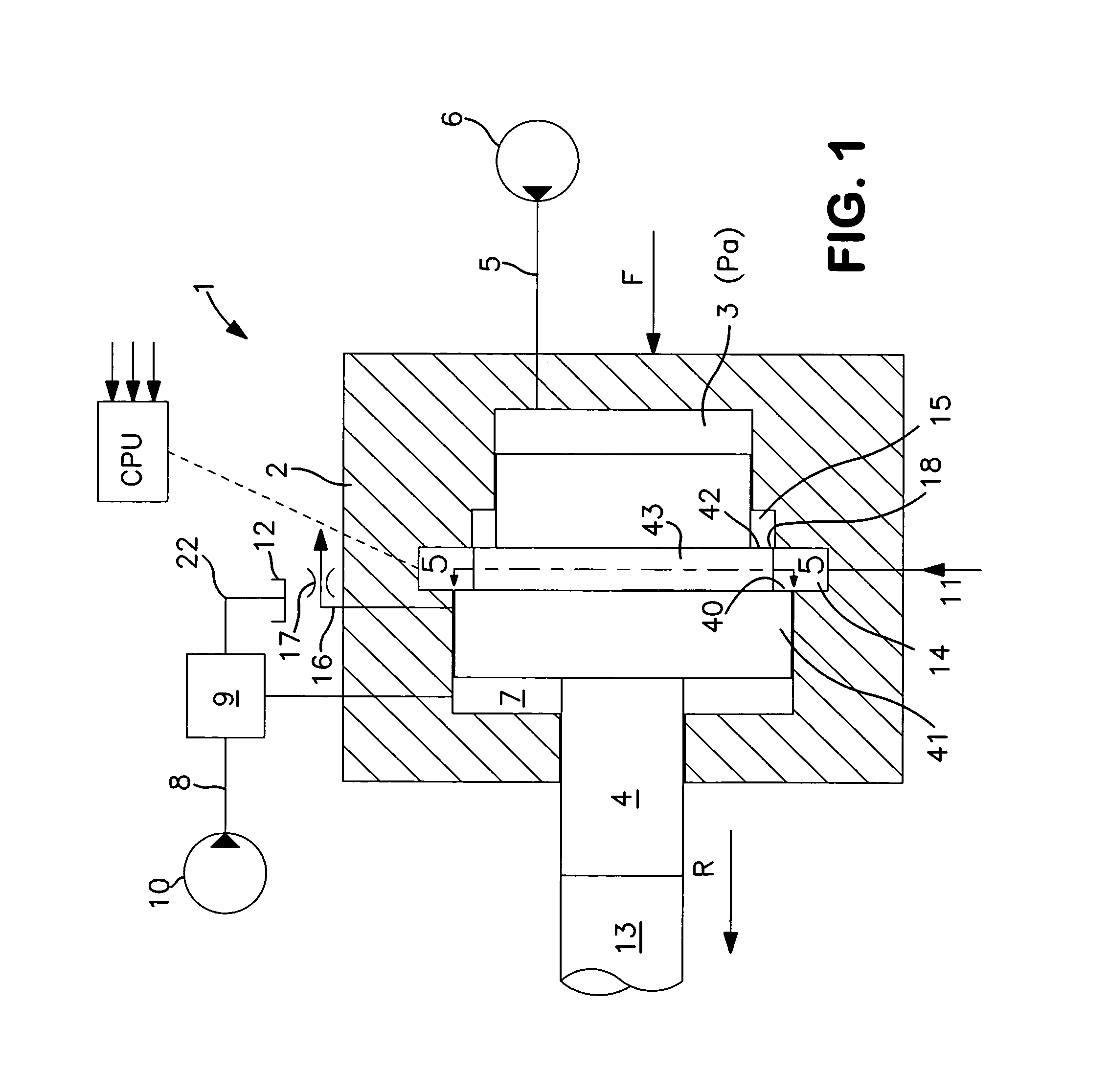

InactiveUS20100032177A1Extend working lifeImprove rock drilling efficiencyConstructionsReciprocating drilling machinesShock waveEngineering

A pulse drilling machine (1; 1′) for the generation of shock wave pulses in a tool direction (R) including a housing (2) wherein an impulse piston (4; 4) is arranged, and including means (9) for abrupt change of a fluid pressure influencing the impulse piston in order to achieve a force resultant on the impulse piston in the tool direction and thereby generate a shock wave pulse in a drill string (13; 13′) which is connected to the machine, wherein inside the housing there is arranged a first fluid chamber (14; 3′) inside which a pressure fluid in operation is arranged to exert a pressure in the tool direction on the impulse piston. The machine is distinguished by a fluid flow channel (11; 18; 19), which includes means for damping a fluid flow flowing from said first fluid chamber through the fluid flow channel obtained when influencing the impulse piston (4; 4′) in a direction opposite to the tool direction (R) by rock reflexes in the drill string during drilling.

Owner:ATLAS COPCO ROCK DRILLS

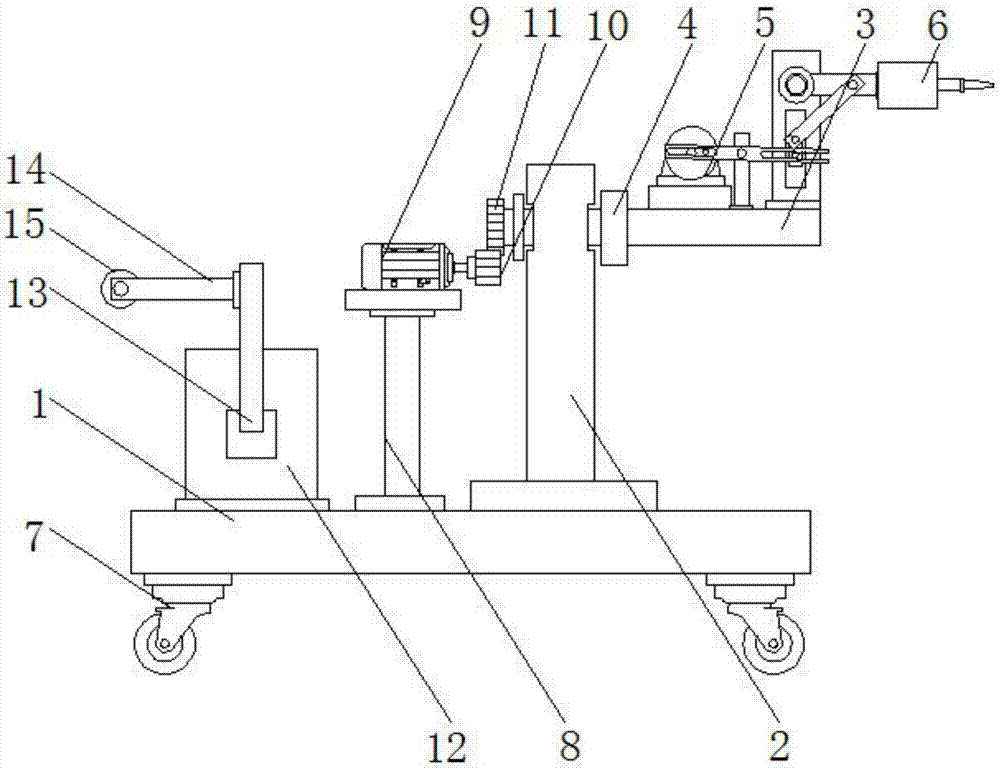

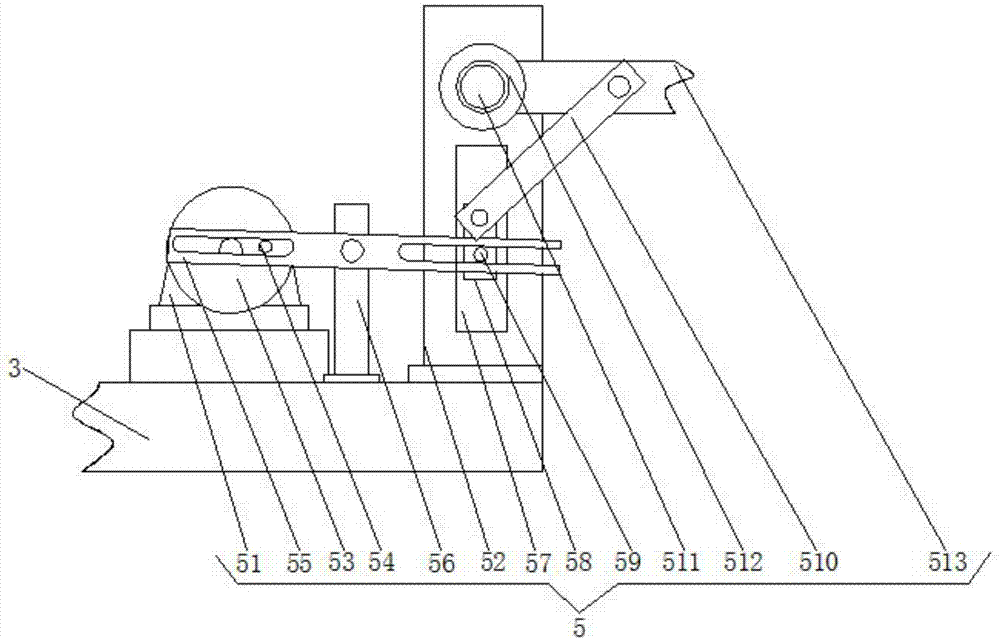

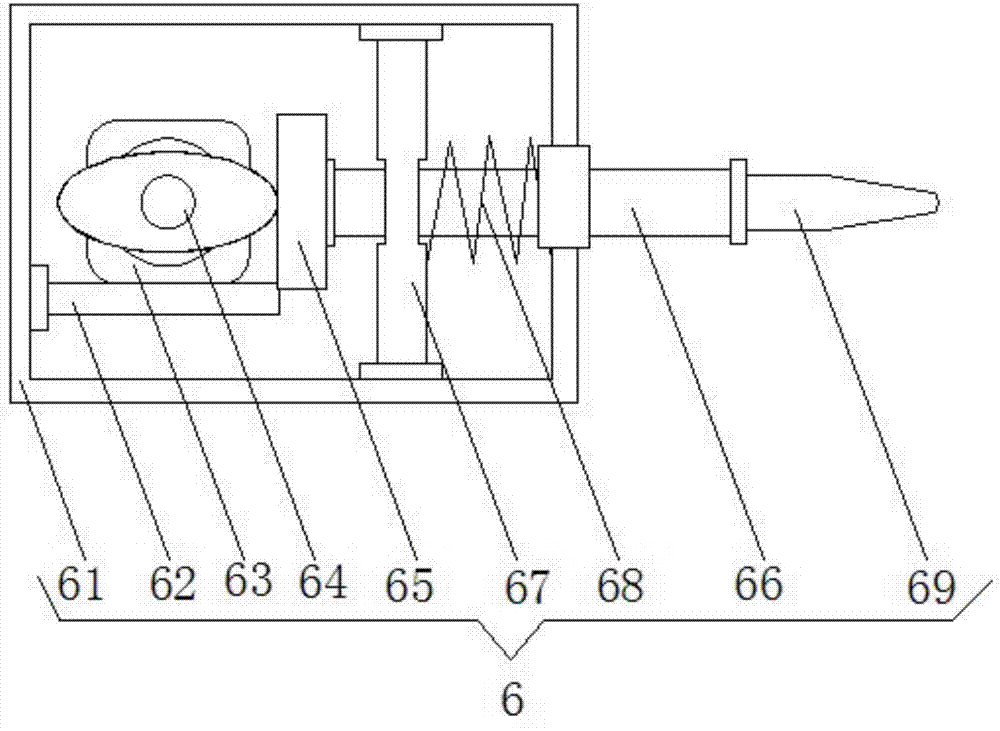

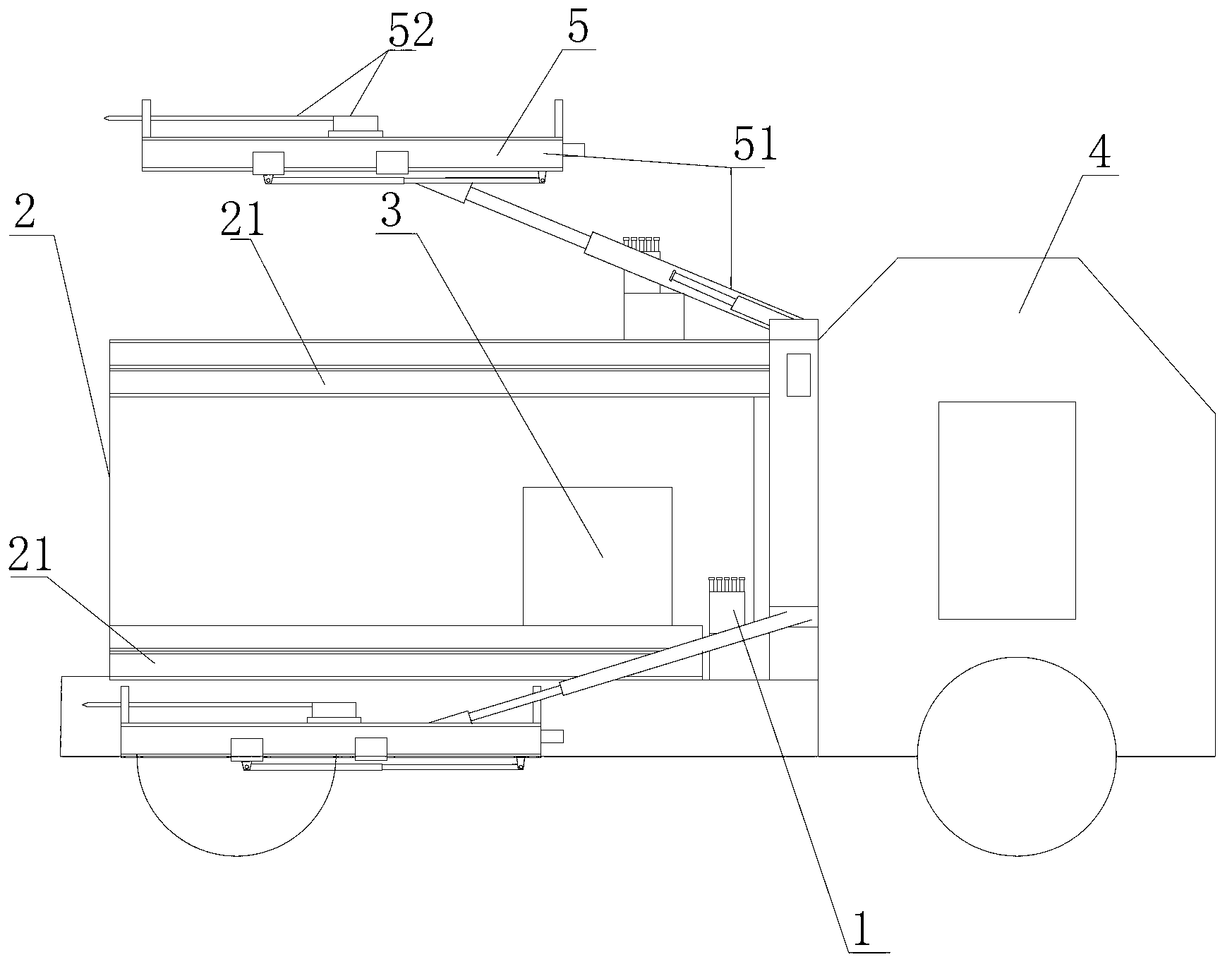

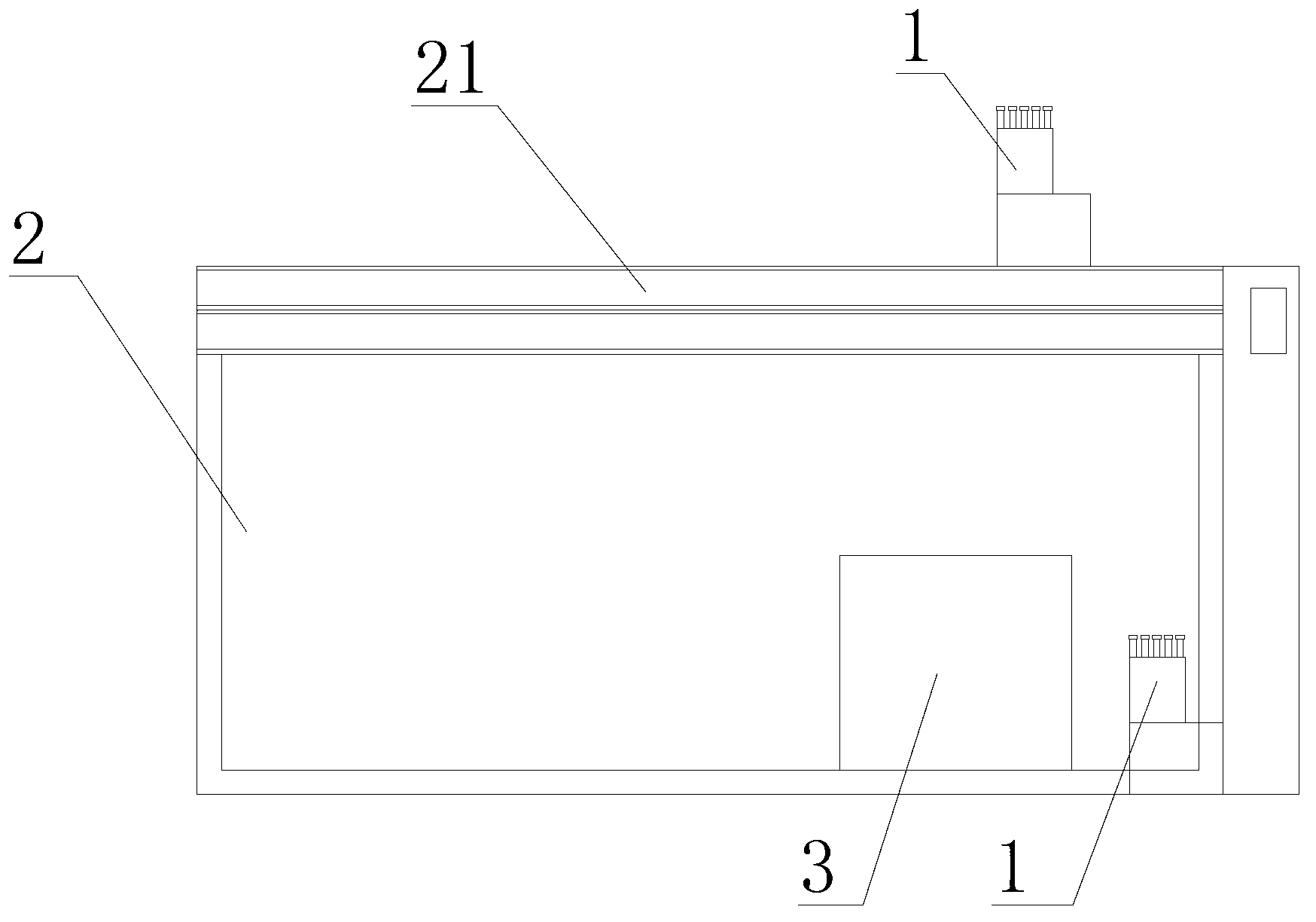

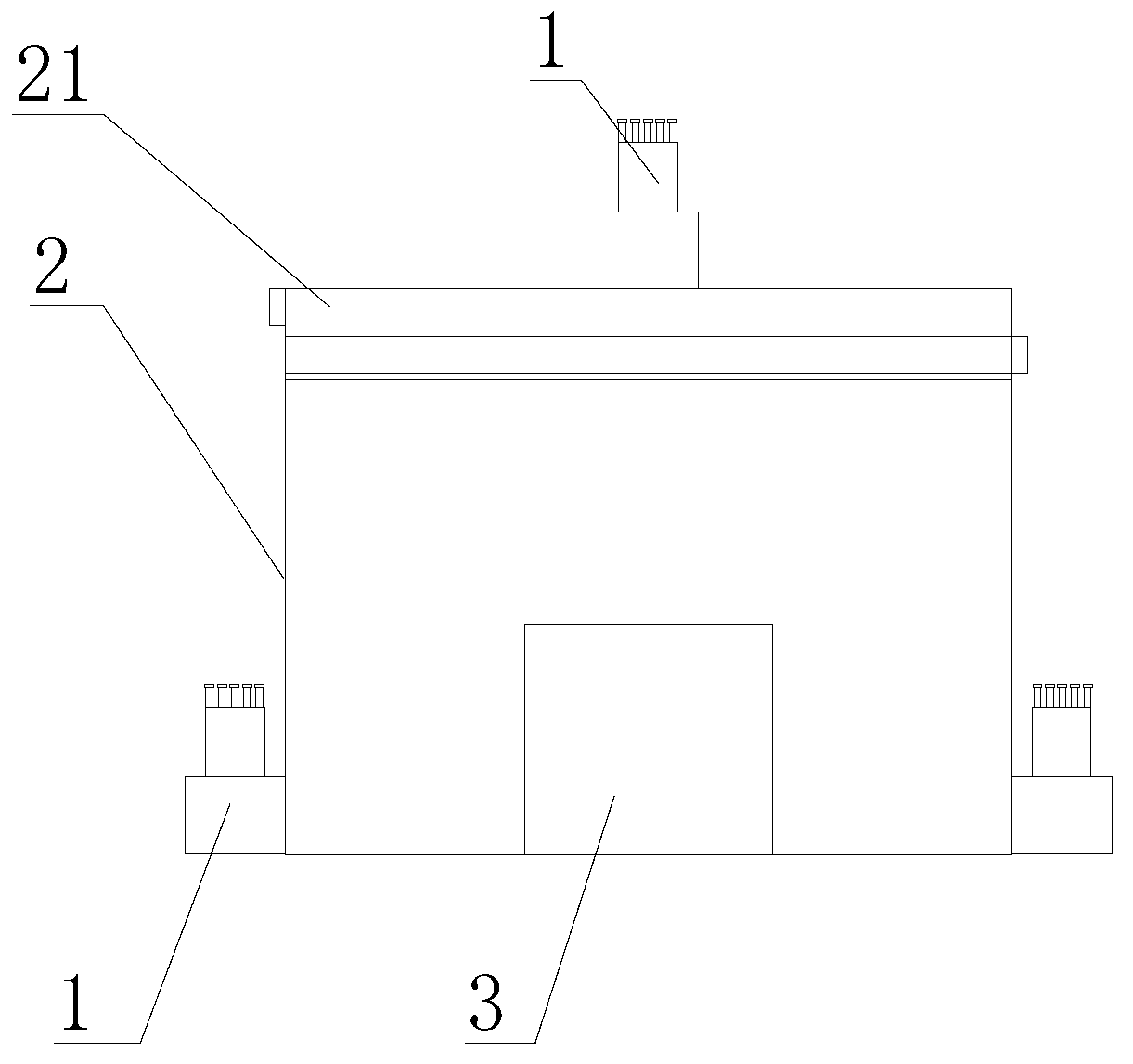

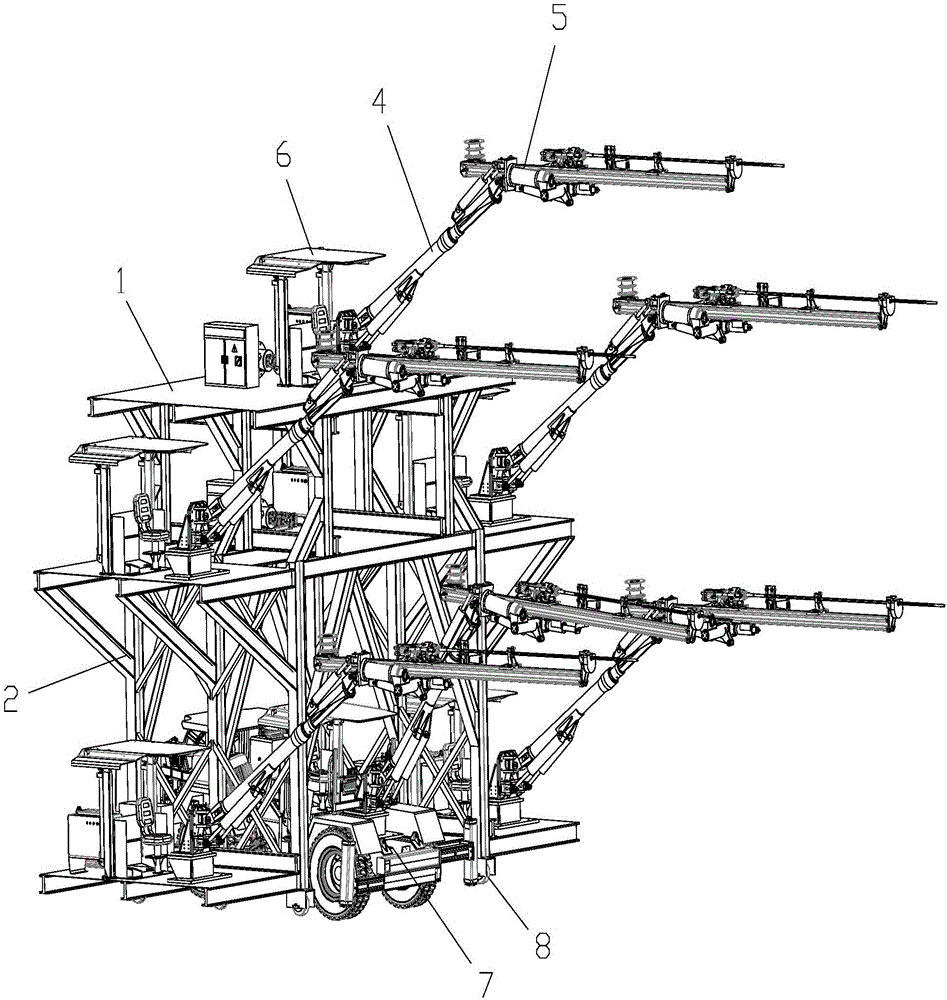

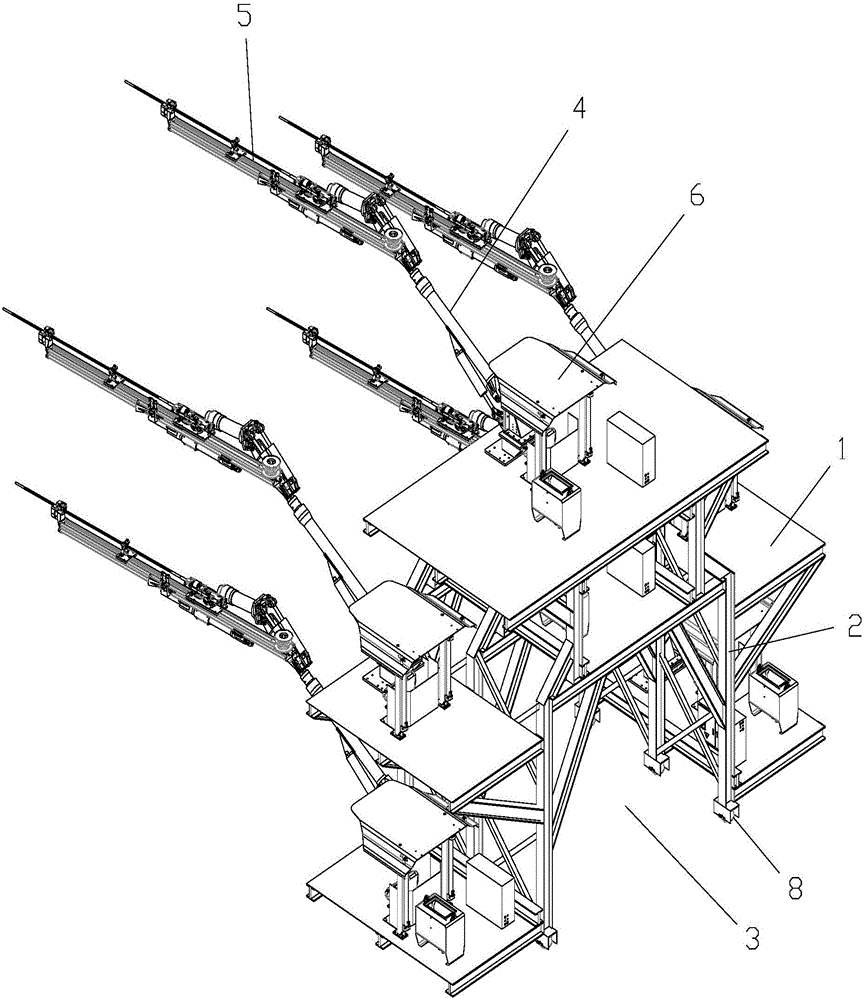

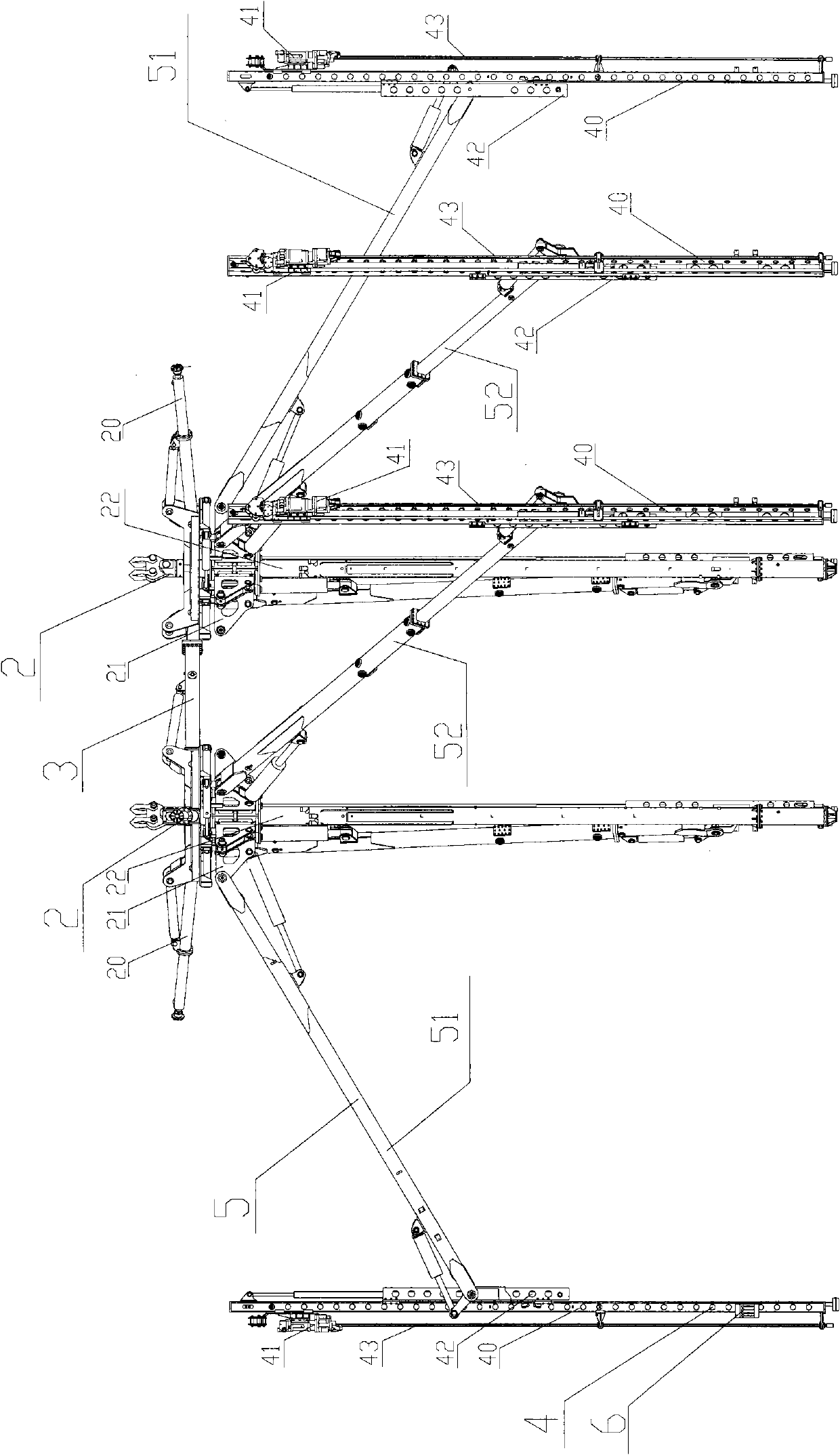

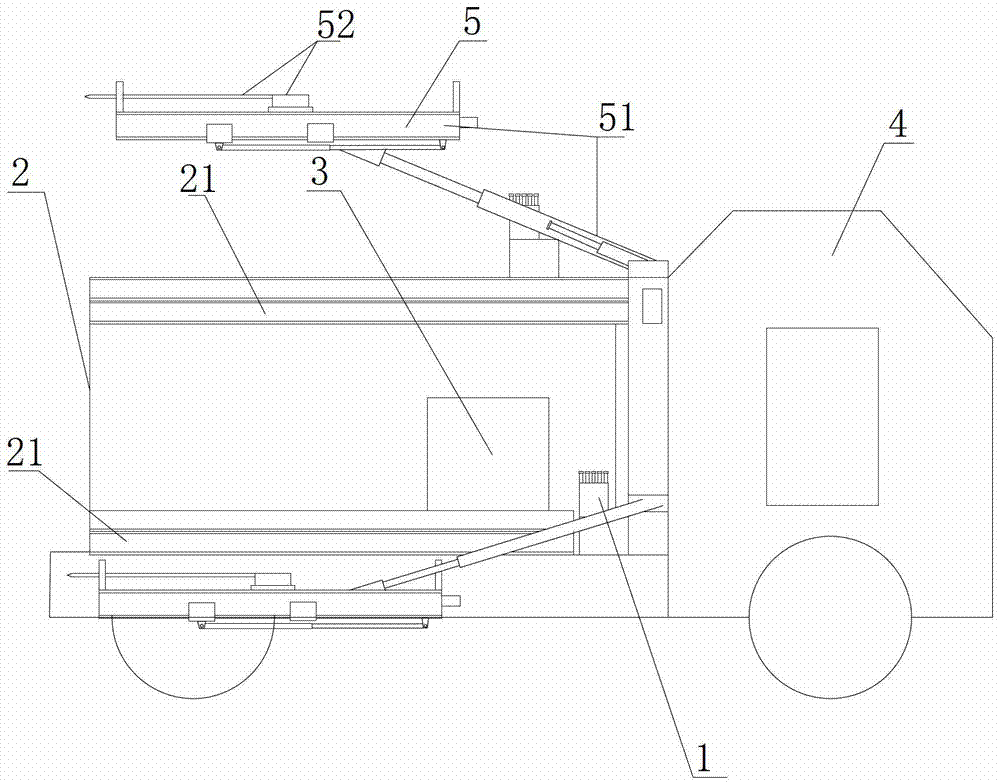

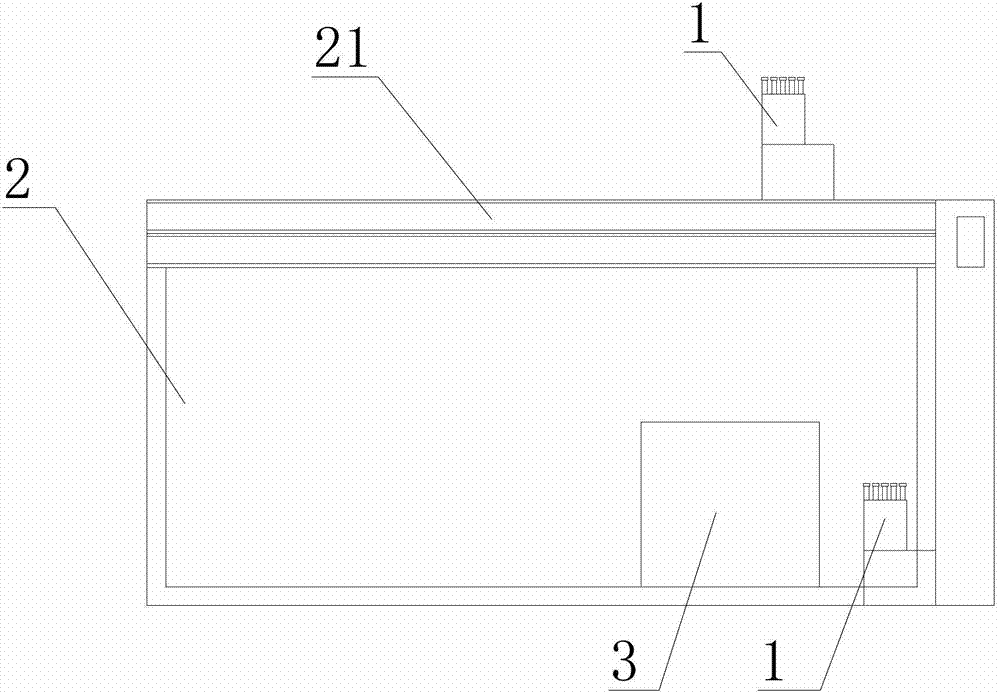

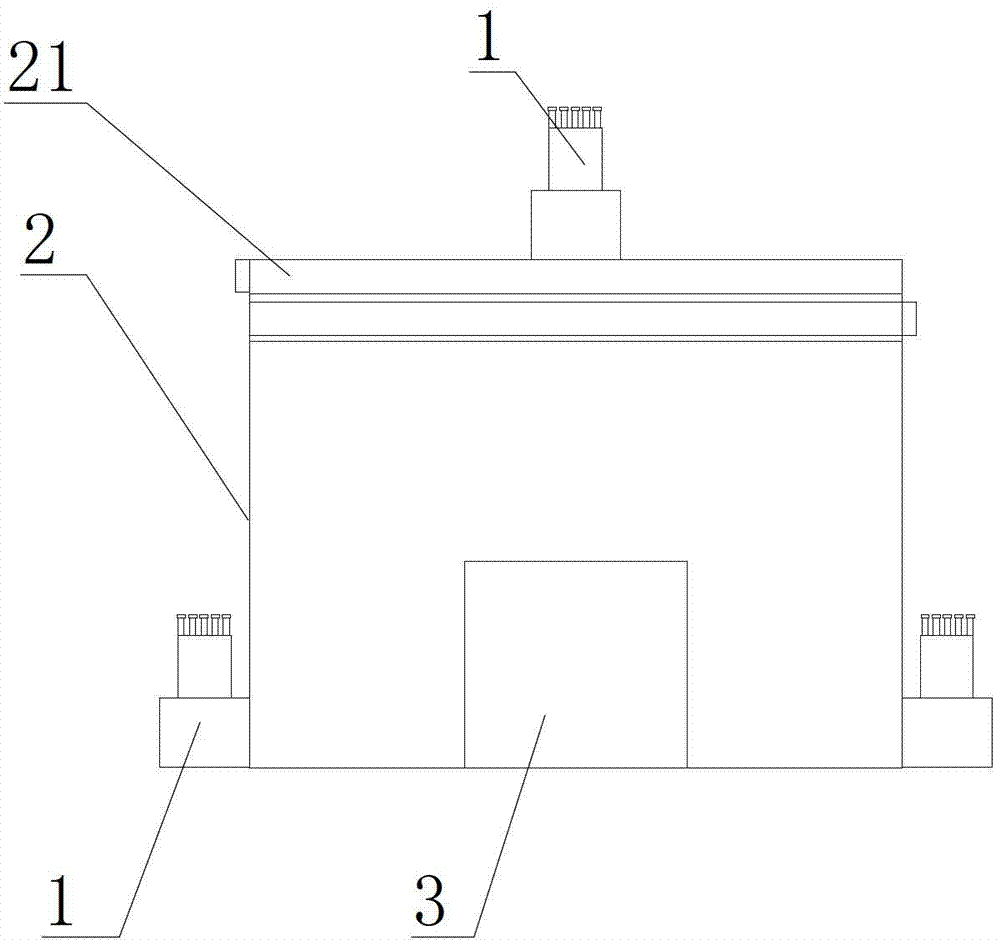

Automatic rock drilling device special for tunnel excavation

The invention relates to an automatic rock drilling device special for tunnel excavation, which has high rock drilling efficiency, is safe for using and contributes to saving time and construction cost. The automatic rock drilling device comprises a control stand, a support frame, a power device, a movable carrier and rock drilling equipment, wherein the support frame is arranged on the carrier; the power device, the control stand and the rock drilling equipment are arranged on the support frame; the power device is connected with the rock drilling equipment through a lead; the control stand is connected with the power device and the rock drilling equipment through leads respectively; the support frame is a square frame body; the support frame body is provided with at least one group of platforms capable of extending and contracting towards both sides; the rock drilling equipment comprises one or more groups of mechanical arms and drill bits arranged on the mechanical arms; one end of each mechanical arm is connected to the frame body; and the other end of each mechanical arm is provided with a drill bit. The automatic rock drilling device has the advantages of high rock drilling efficiency, use safety, saving in time and construction cost, and the like.

Owner:游天义

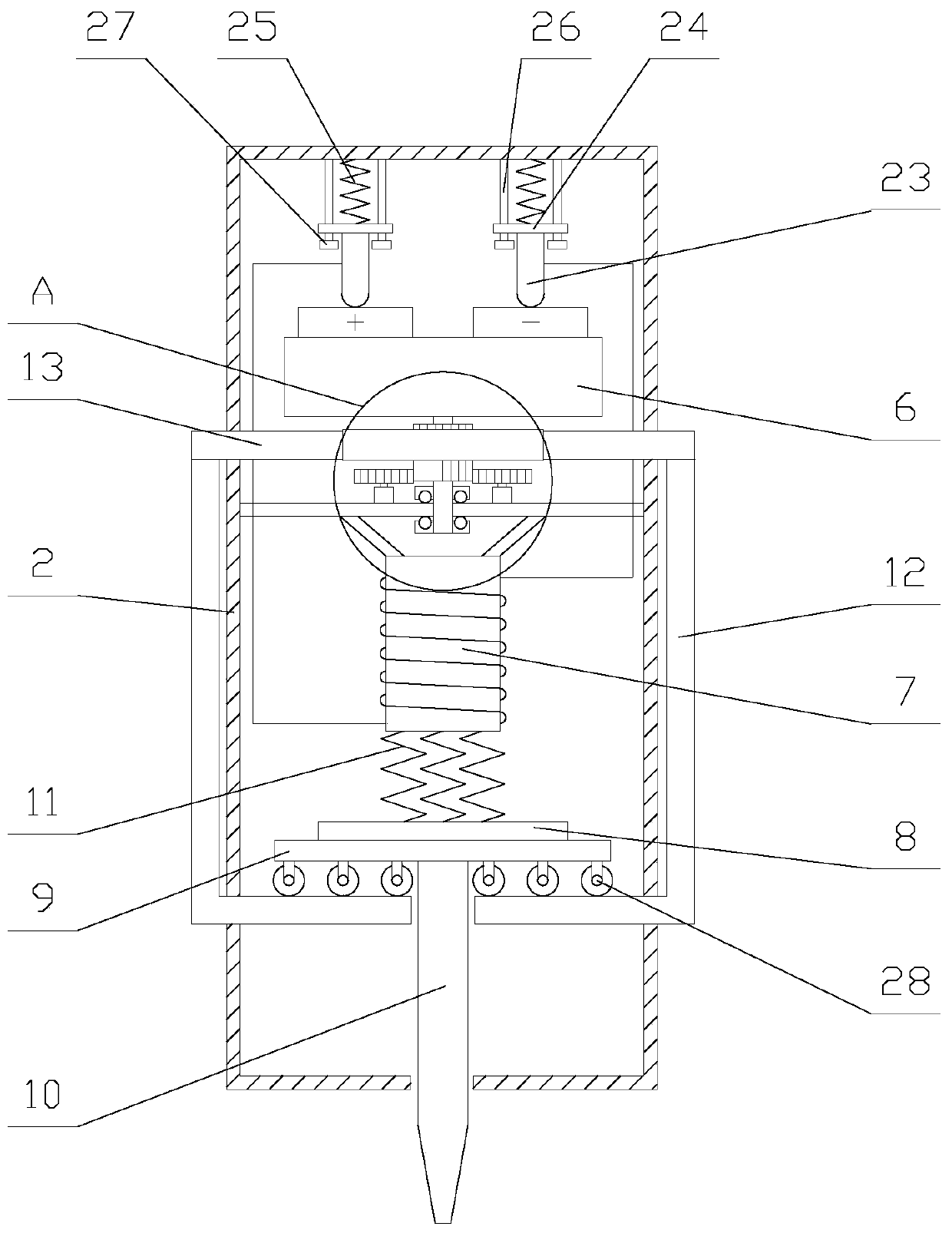

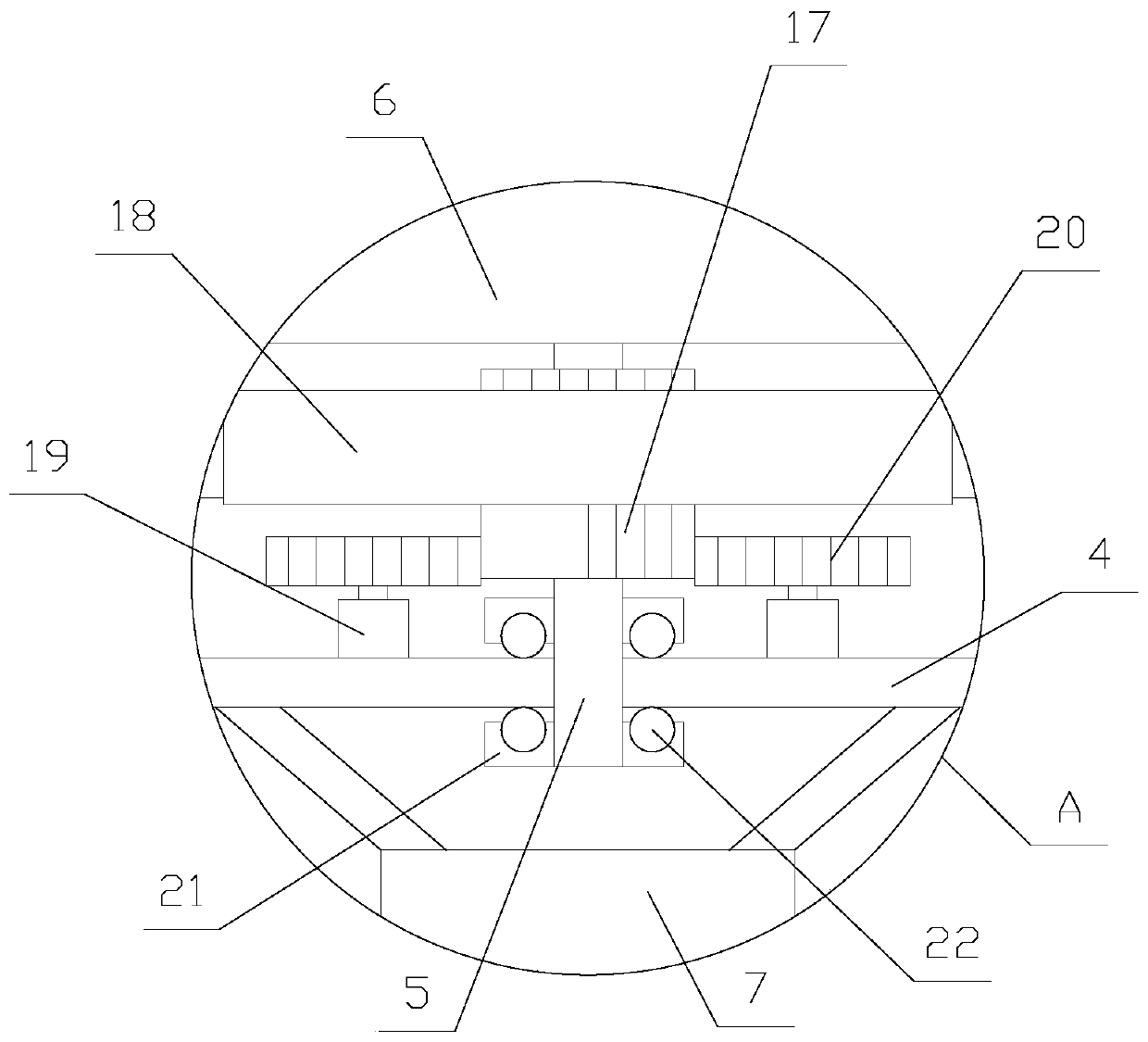

Electric percussion jackdrill

ActiveCN111088952AAdjust the speedIncrease speedDrill bitsDerricks/mastsElectric machineRock cutting

The invention discloses an electric percussion jackdrill. The electric percussion jackdrill comprises an outer box. The front and rear walls of the outer box are fixedly provided with short shafts infront-back symmetry. Fixing devices used for turning the direction of the outer box and fixing the outer box are rotatably connected to the short shafts. The outer box is internally provided with an outer box cavity. An inner box slidably connected to the upper and lower walls of the outer box cavity and extending out of the outer box penetrates through the left wall of the outer box cavity. The angle of the electric percussion jackdrill can be freely adjusted. The electric percussion jackdrill is convenient to use and safer in use and does not need to be supported by hand. Compared with othertypes of jackdrill not requiring hand supporting, the electric percussion jackdrill provided by the invention is small in weight and convenient to carry, manage and repair. A variable frequency motoris adopted. When used for large rocks, the rotation speed of the motor can be adjusted, and the rock drilling efficiency is improved. The electric percussion jackdrill is low in usage noise, free ofexhaust emission, clean, free of pollution and relatively better in working environment.

Owner:核工业金华建设集团有限公司

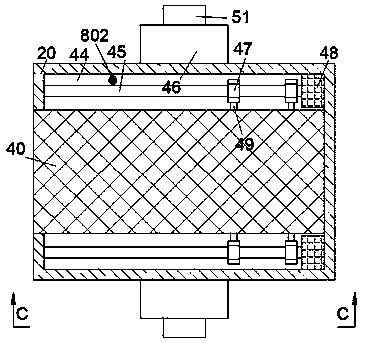

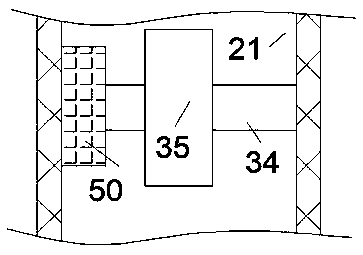

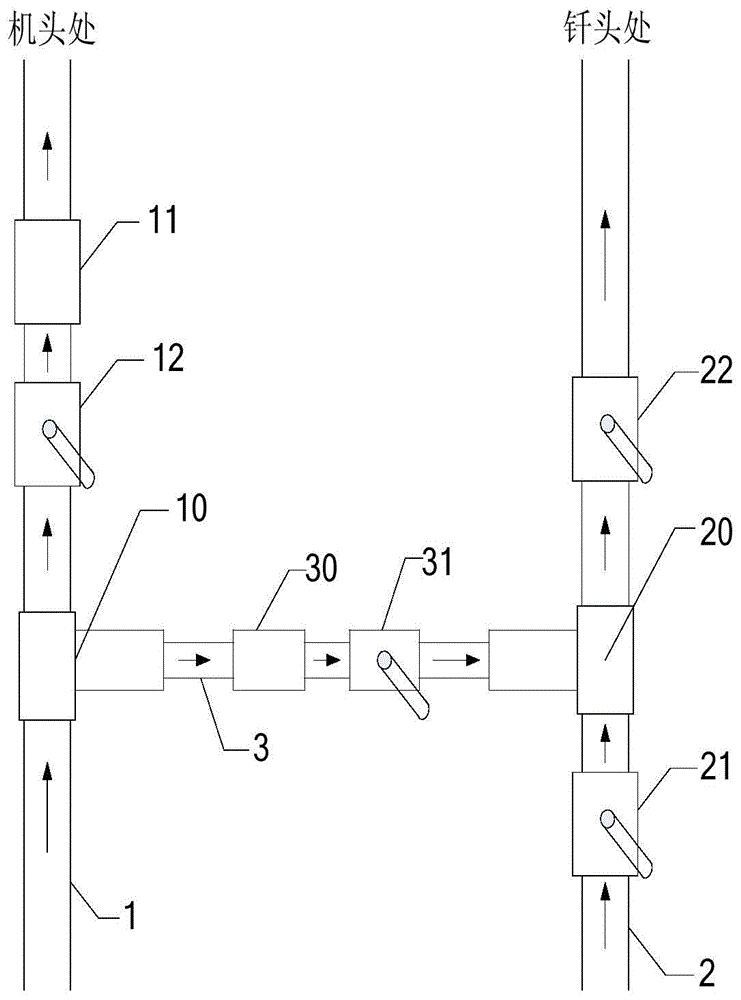

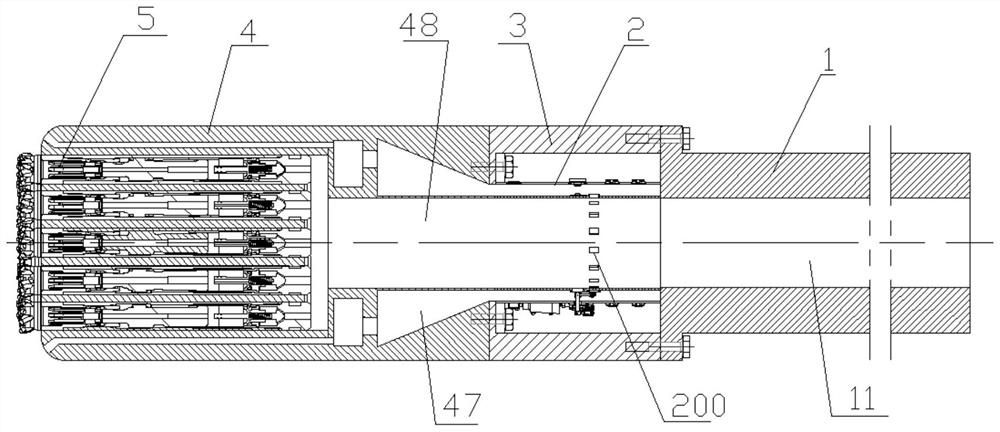

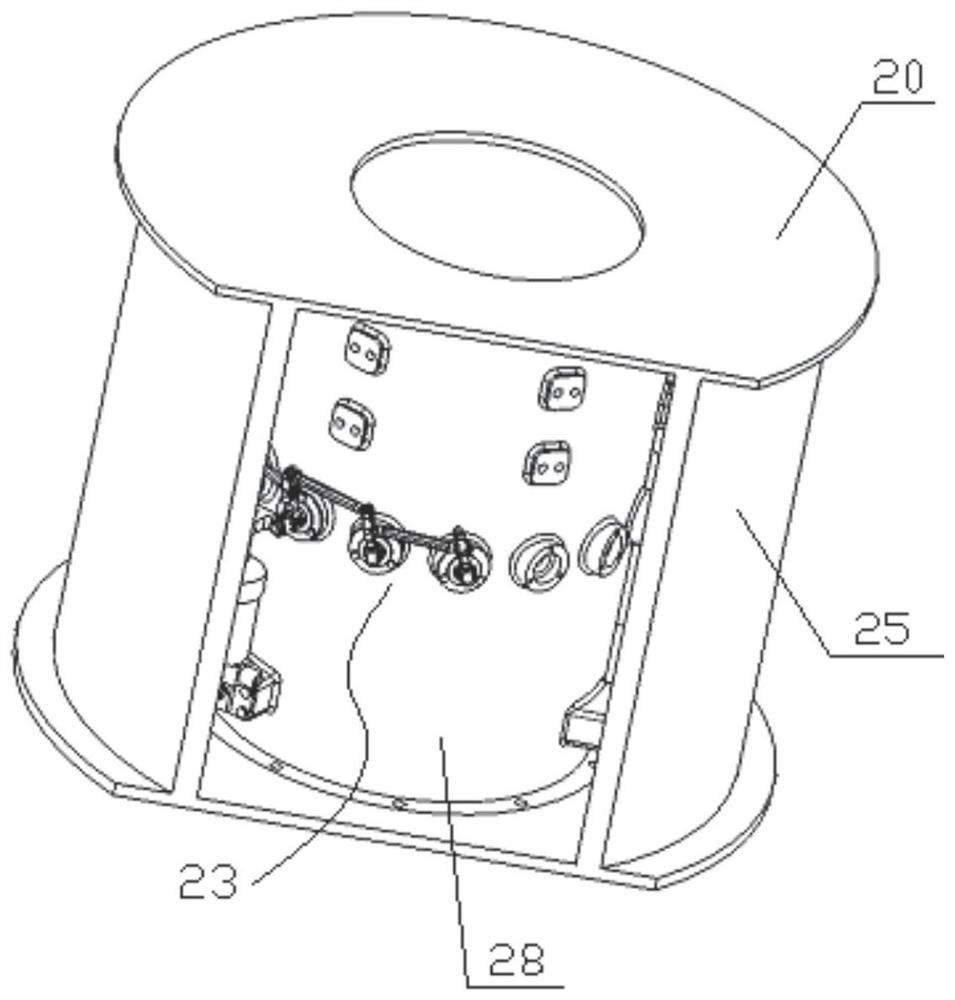

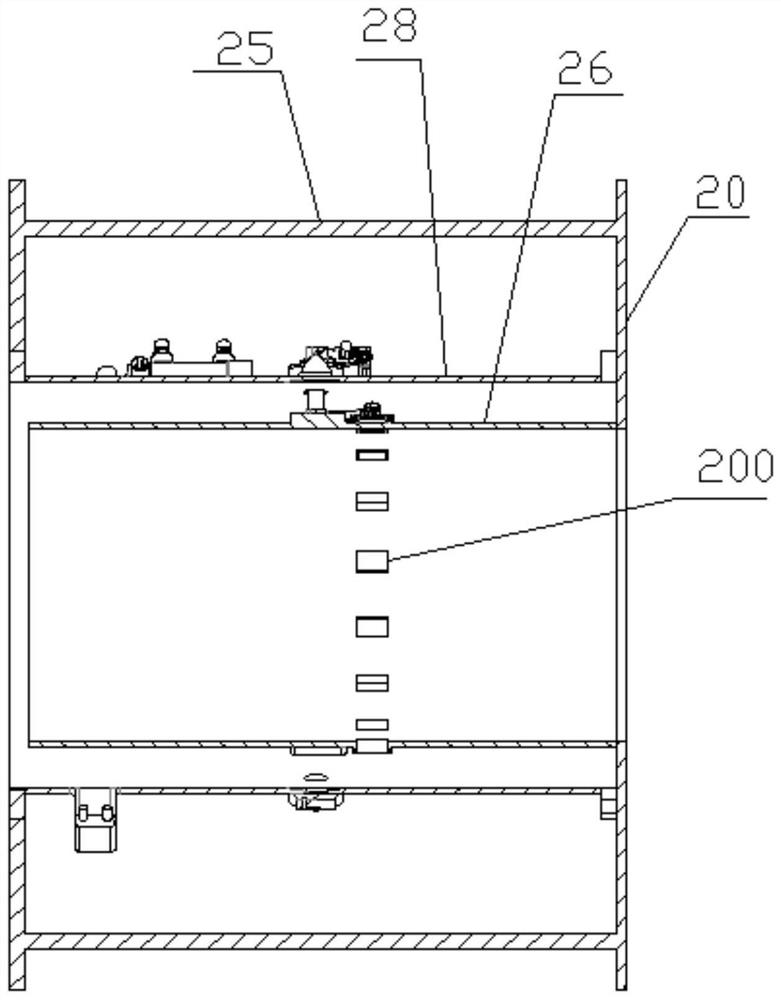

Modular full-hydraulic rock drilling system

InactiveCN106089224AReduce labor intensityImprove rock drilling efficiencyTunnelsModularityHigh pressure water

The invention discloses a modular full-hydraulic rock drilling system which comprises a rock drilling rack. The rock drilling rack comprises three layers of horizontal workbenches and supports for connecting the three layers of horizontal workbenches. The middle of the support for connecting the first layer of horizontal workbench and the second layer of horizontal workbench is provided with a portal channel. The system further comprises rock drilling devices arranged on the three layers of horizontal workbenches respectively, protective sheds arranged on the three layers of horizontal workbenches and used for protecting rock drill operators respectively, and a rock drilling carriage arranged in the portal channel. According to the modular full-hydraulic rock drilling system, the operation face can cover the whole tunnel section, the rock drilling efficiency is high, the labor intensity of the operators is low, the exhaust and noise pollution problems of a pneumatic rock drilling machine are eliminated, high-pressure water can be adopted in the rock drilling process of a hydraulic rock drilling machine for removing dust, the dust pollution problem can be avoided, meanwhile, the protective sheds are arranged on the rock drilling rack so as to protect the operators, and operation safety is high; in addition, the rock drilling system is modularly designed and is convenient to assemble.

Owner:重庆格德瑞重工智能装备研究院

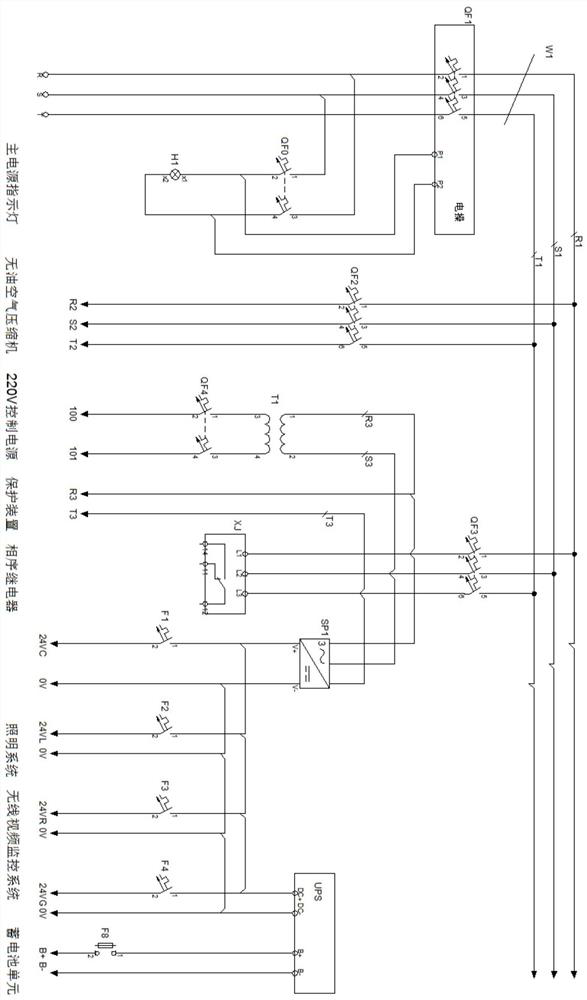

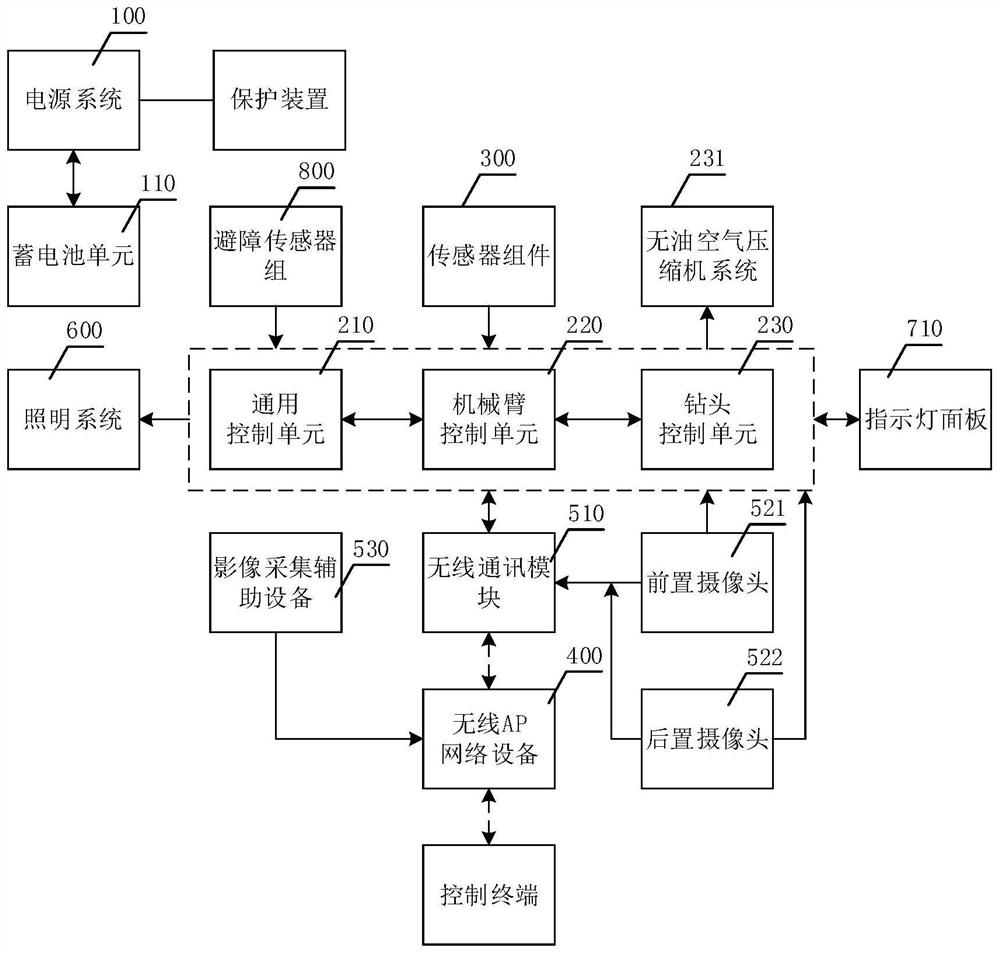

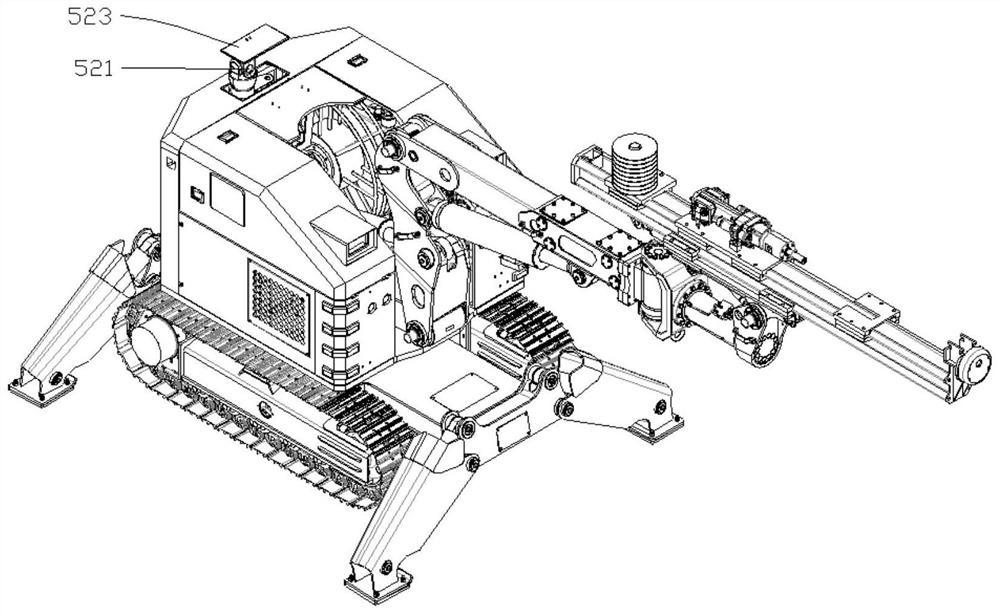

Electrical control system of rock drilling robot and rock drilling robot

PendingCN112392499AStable jobRealize automatic controlTunnelsSimultaneous control of multiple variablesControl cellRock cutting

The invention discloses an electrical control system of a rock drilling robot and the rock drilling robot. The rock drilling robot comprise a power supply system, a universal control unit, a drill bitcontrol unit, a sensor assembly, wireless AP network equipment, a wireless communication module and a plurality of image acquisition devices. The universal control unit is used for driving a rock drilling robot body to walk and rotate and controlling unfolding and folding of a cable. The drill bit control unit is used for adjusting the working state of a chisel bit. The mechanical arm control unit is used for adjusting the posture of a mechanical arm. The sensor assembly is used for detecting hydraulic oil state parameters, walking postures and mechanical arm postures of the rock drilling robot body. The wireless communication module is used for carrying out data interaction with a control terminal through the wireless AP network equipment. The image acquisition devices are used for assisting the drill bit in locating and obtaining environment information around the rock drilling robot. According to the electrical control system of the rock drilling robot and the rock drilling robot,the whole working area of the rock drilling robot can have stable wireless communication capability by erecting the wireless AP network equipment, remote control can be realized through a wireless video monitoring system, and meanwhile, the mechanical arm can be assisted to realize automatic searching of a rock drilling and blasting position.

Owner:湖南创远智能发展有限责任公司

Method for achieving fine blasting by replacing vertical deep hole with downward fan-shaped deep hole

The invention provides a method for achieving fine blasting by replacing a vertical deep hole with a downward fan-shaped deep hole, and relates to the technical field of exploration. The method is characterized by comprising the following steps of stoping and rock drilling, optimization of stoping design, design of a stoping process for the downward fan-shaped deep hole, determination of blastingparameters, priming circuit connection, perforating deviation correction, determination of explosive charging requirements, and explosive charging and blasting. The method is reasonable, the workloadcan be reduced, the equipment utilization rate can be increased, and the working pace is quickened.

Owner:安徽马钢张庄矿业有限责任公司

Mining medium-length hole drilling and blasting method

PendingCN113847033AImprove rock drilling efficiencyReduce chargeUnderground miningBlastingDetonatorMining engineering

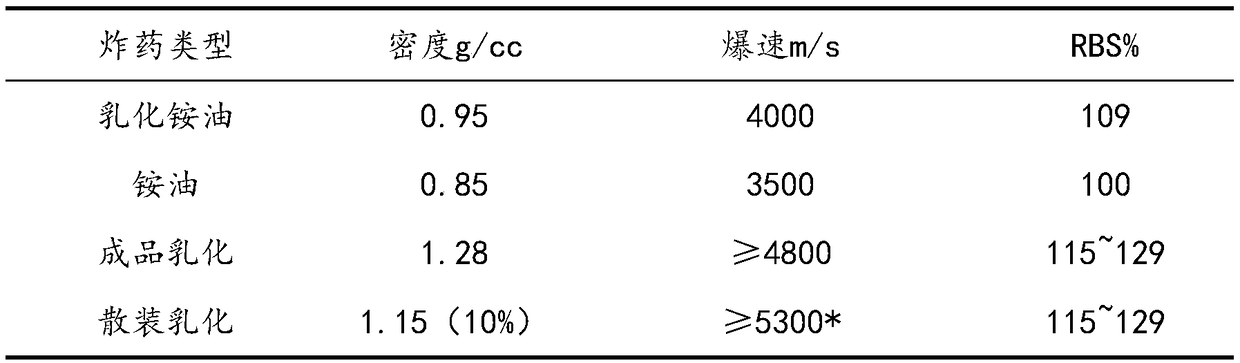

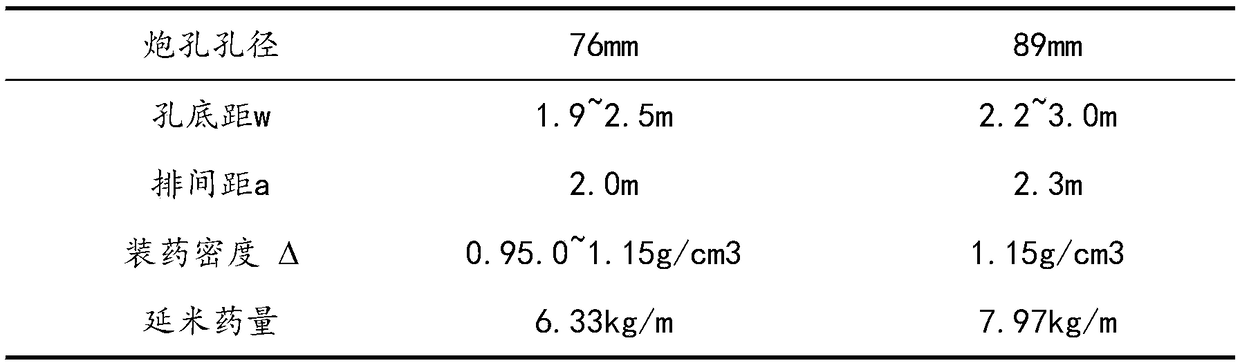

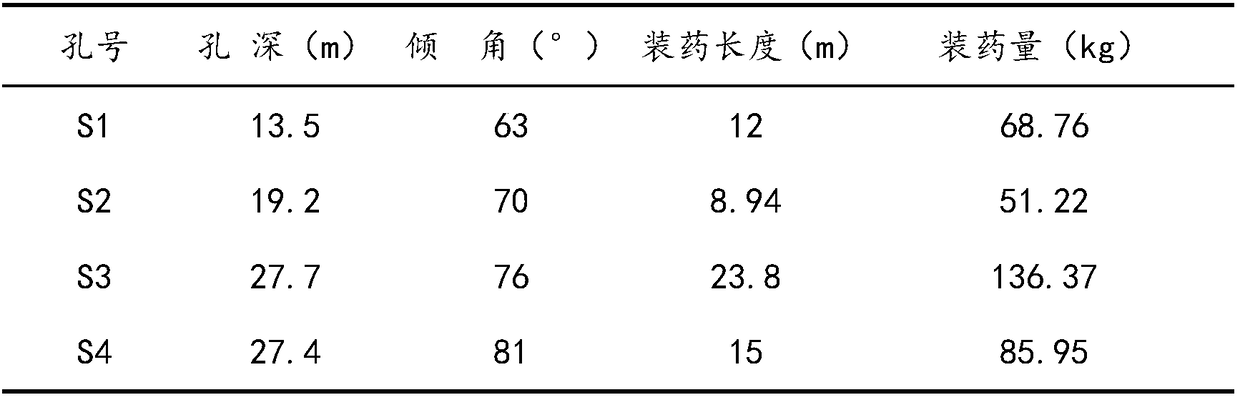

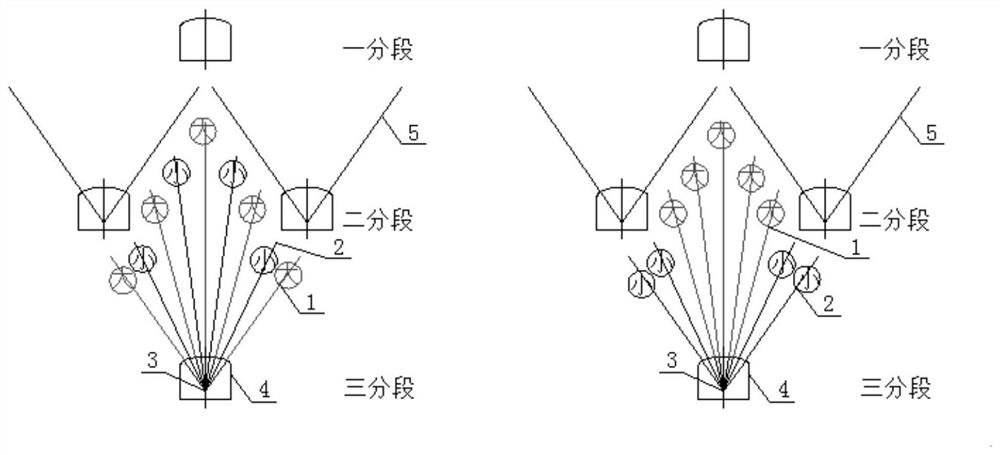

The invention discloses a mining medium-length hole drilling and blasting method, and relates to the technical field of underground mining. The mining medium-length hole drilling and blasting method comprises the steps that medium-length holes in mining are constructed by pneumatic or hydraulic drilling equipment in a subsection plane stoping route and then are charged and blasted, the whole medium-length holes in mining are arranged in a fan-shaped or parallel mode, and more than two different diameters are arranged in a staggered or bunchy mode; and charging blasting is carried out according to different arrangement forms, large-diameter blast holes are firstly detonated, and small-diameter blast holes are then detonated. The small-diameter blast holes are high in rock drilling efficiency, small in explosive loading amount and less in harmful gas generated by blasting, the rock drilling and blasting cost can be reduced under the condition that the blasting effect is not affected, so that the mining efficiency is improved, and the mining cost is reduced; and the blast holes with different diameters are detonated by different sections of detonators, the large-diameter blast holes play a main blasting role and are detonated firstly, and the small-diameter blast holes play an auxiliary blasting role and then are detonated, so that blasting shock waves and seismic waves are reduced.

Owner:海南矿业股份有限公司

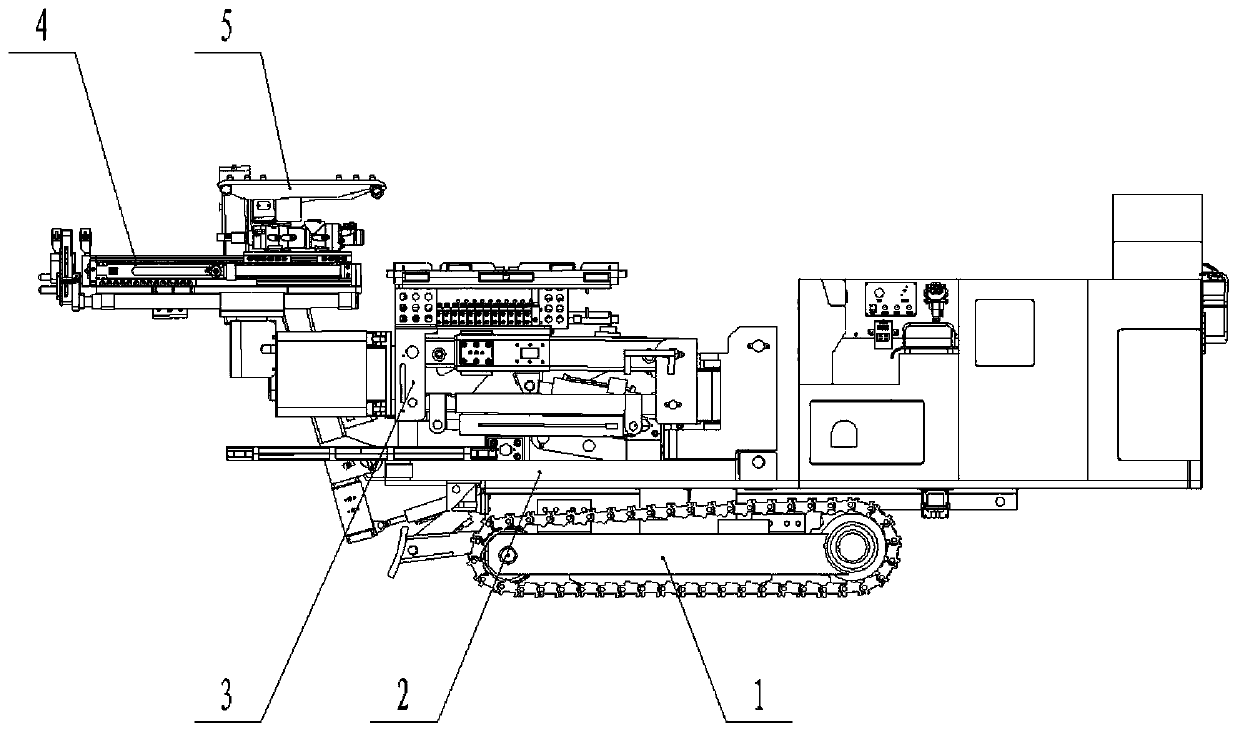

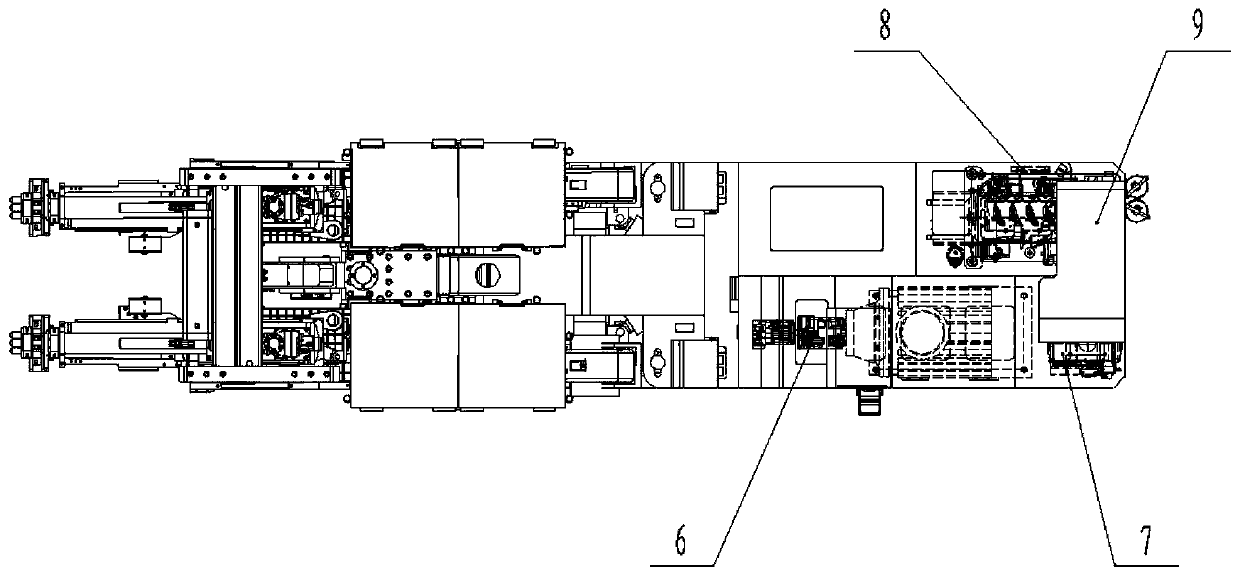

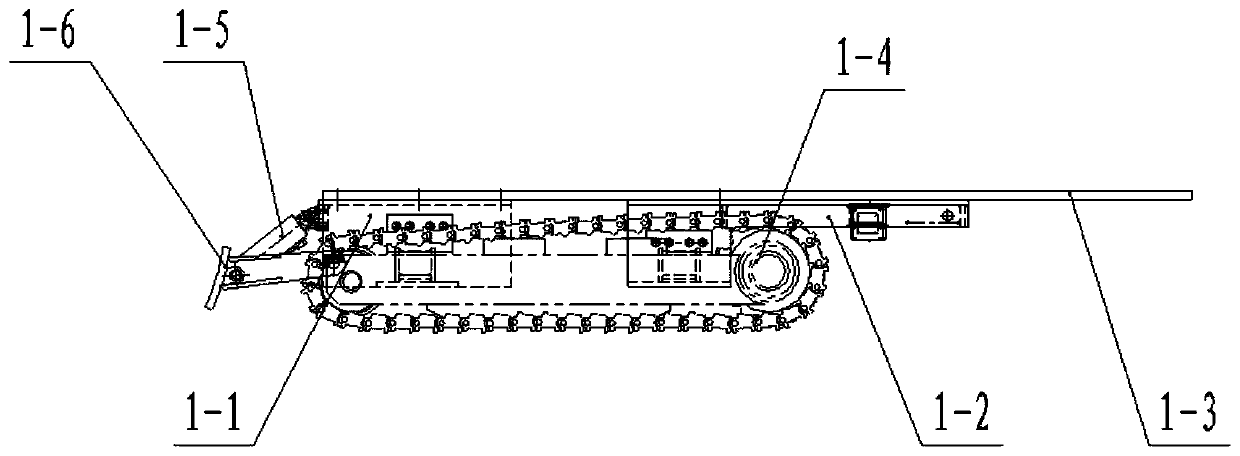

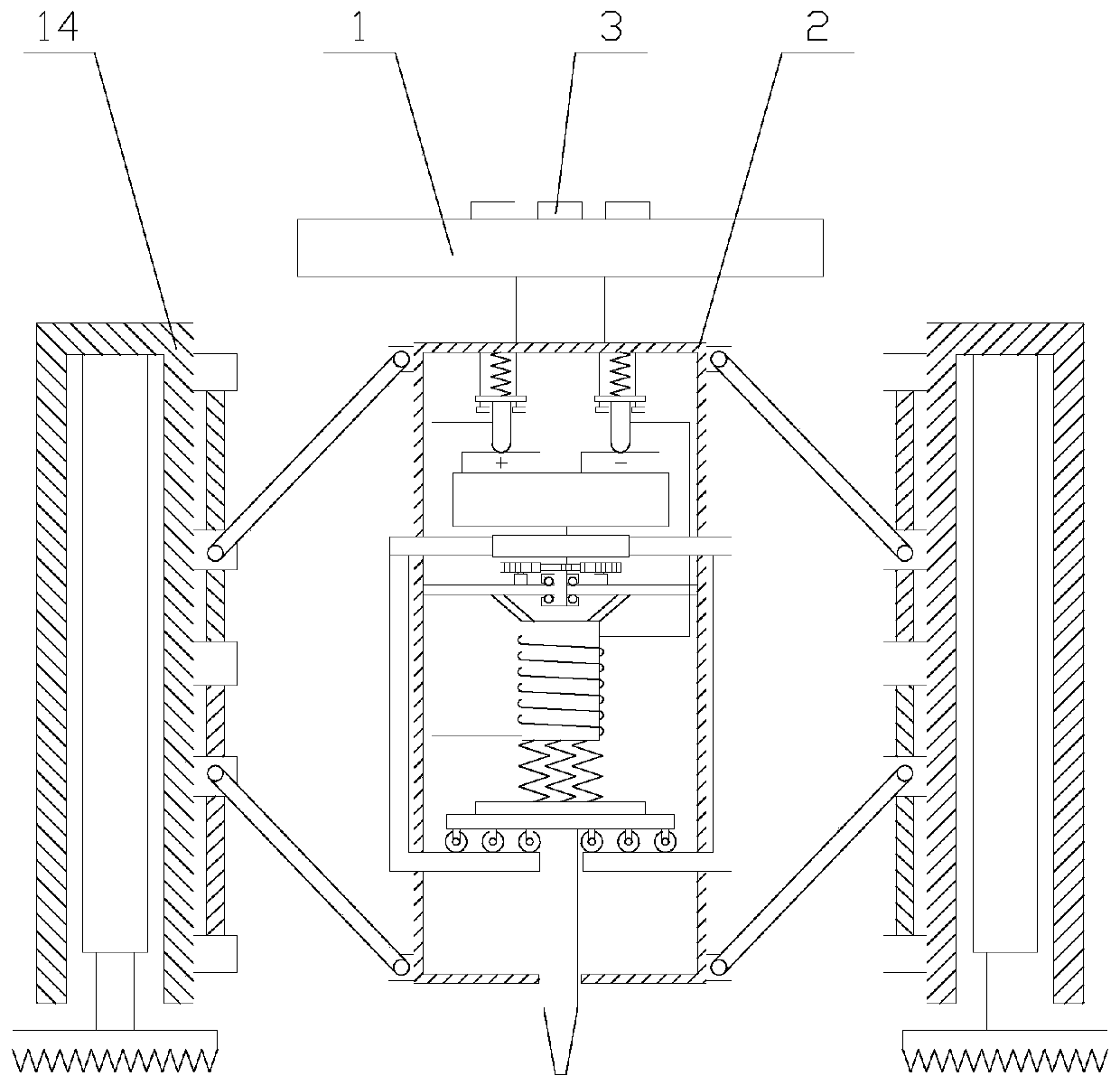

Oil-electricity hybrid dual-power multi-functional impacting rock-drilling drilling vehicle

PendingCN111425134ACompact structureSmall turning radiusDerricks/mastsDirectional drillingRock cuttingMachine

The invention belongs to the technical field of mine rock drilling machinery, and particularly relates to an oil-electricity hybrid dual-power multi-functional impacting rock-drilling drilling vehicle. According to the technical scheme, the oil-electricity hybrid dual-power multi-functional impacting rock-drilling drilling vehicle comprise a machine body part, a lifting part, two drilling arms, two on-machine drilling machines, a front support, a hydraulic system, an electrical system, a power system and a lubricating system. The lifting part is mounted in an intermediate position above the body part. The two drilling arms are symmetrically arranged on the left side and the right side of the lifting part. The rear end of the drilling arm is hinged to the rear end of the lifting part. The two on-machine drilling machines are symmetrically mounted at the front ends of the two drilling arms. The front support is mounted at the front end of the lifting part. The hydraulic system is mountedat the middle position on the left side of the machine body part. The electric system is mounted on the left rear side of the machine body part. The power system is mounted on the right rear side ofthe machine body part. The lubricating system is mounted on the electrical system and the power system. The oil-electricity hybrid dual-power multi-functional impacting rock-drilling drilling vehicleis high in rock drilling efficiency and good in rock drilling performance, is suitable for mine tunneling roadways, and is very suitable for rock roadway mining operation in China.

Owner:SHANXI TIAN JU HEAVY IND

Rock drilling method and rock drilling machine

InactiveUS8215414B2Extend working lifeImprove rock drilling efficiencyReciprocating drilling machinesConstructionsShock waveEngineering

A pulse drilling machine (1;1′) for the generating of shock wave pulses in a tool direction (R) has an impulse piston (4;4′) with a housing (2), and a device (8) for abruptly changing fluid pressure influencing the impulse piston to achieve a force resultant on the impulse piston in the tool direction to generate a shock wave pulse in a drill string (13; 13′) which is connected to the machine, a first fluid chamber (14;3′) inside the housing which in operation is arranged to exert a pressure in the tool direction on the impulse piston. The machine has a fluid flow channel (11; 18; 19), which includes a device for damping fluid flow flowing from the first fluid chamber through the fluid flow channel obtained when influencing the impulse piston (4; 4′) in a direction opposite to the tool direction (R) by rock reflexes in the drill string during drilling.

Owner:ATLAS COPCO ROCK DRILLS

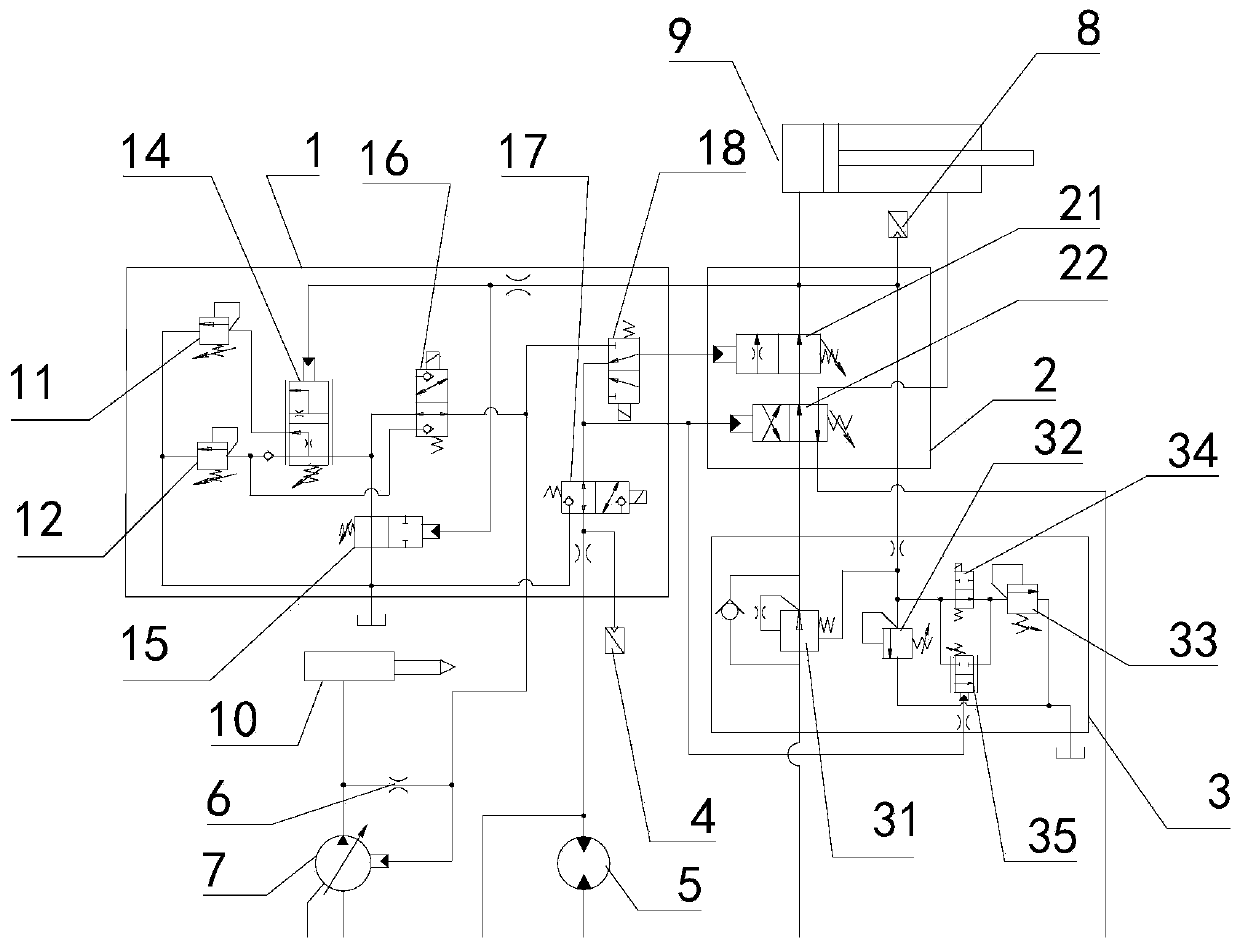

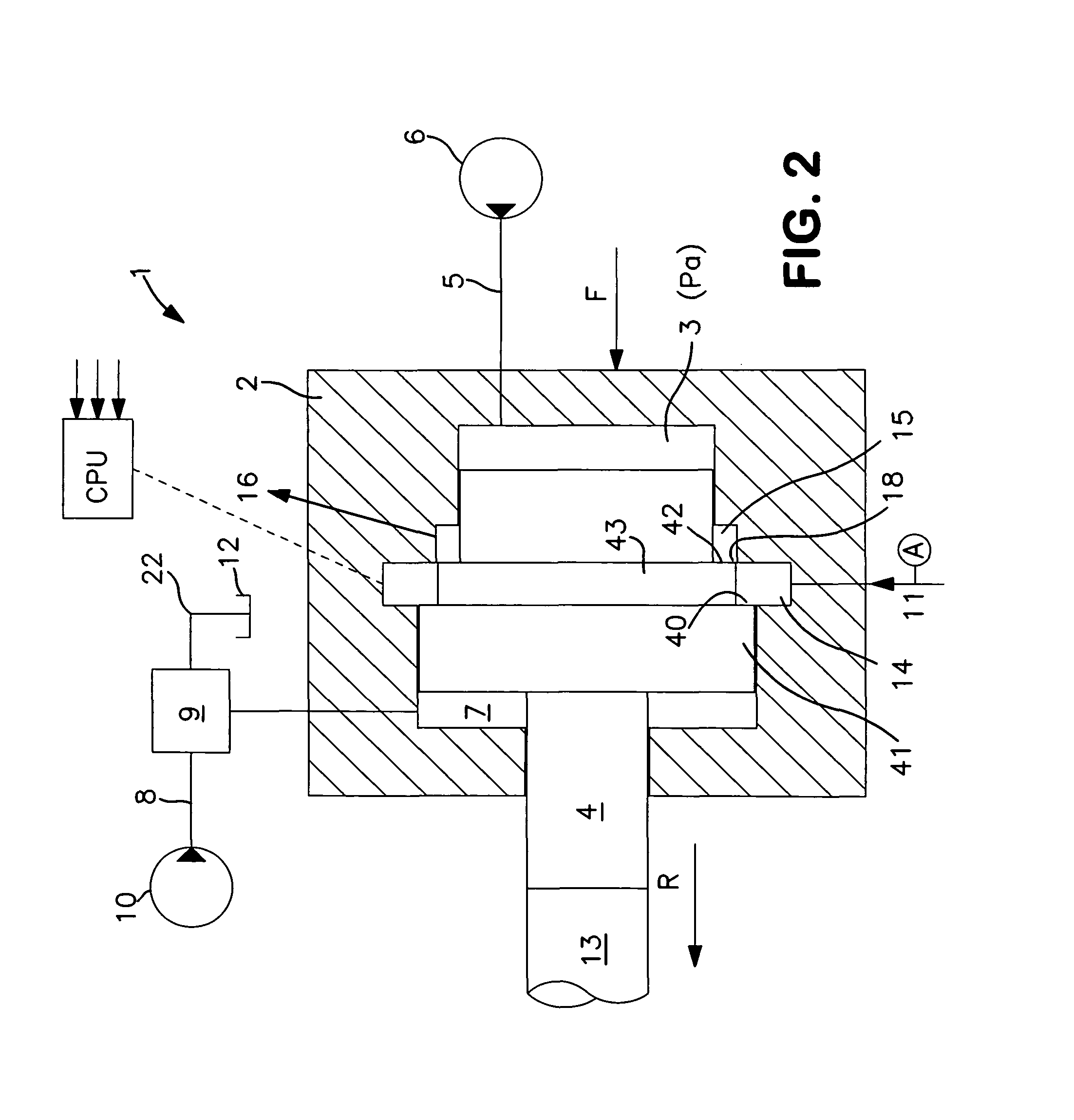

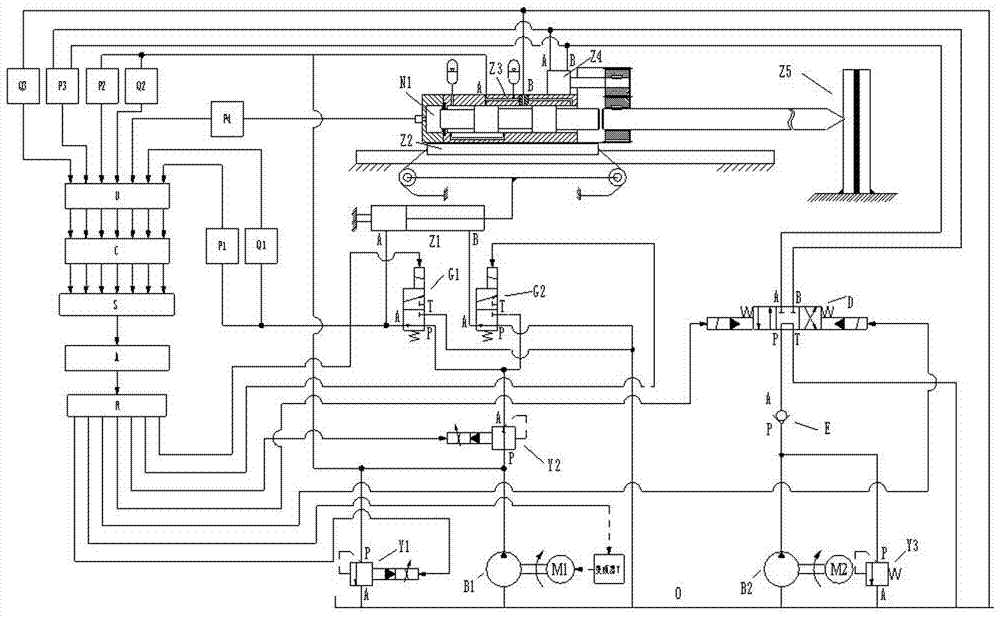

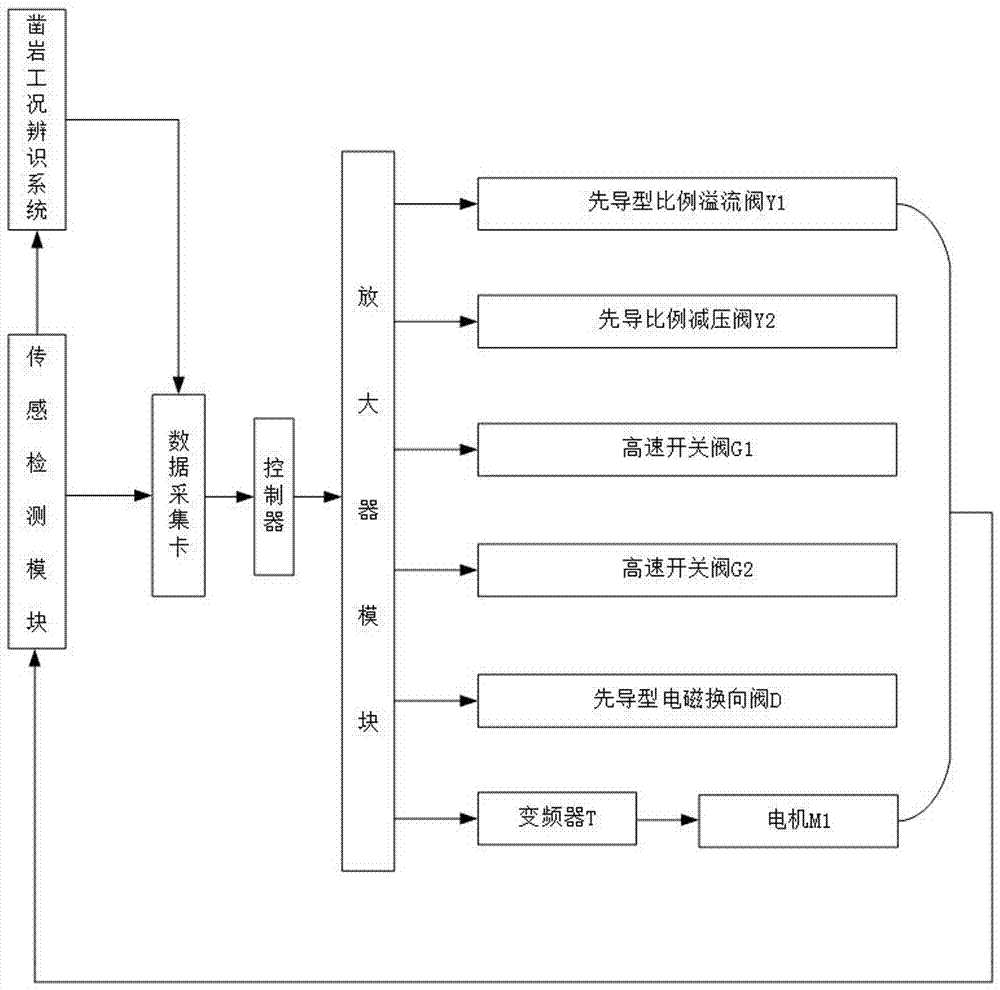

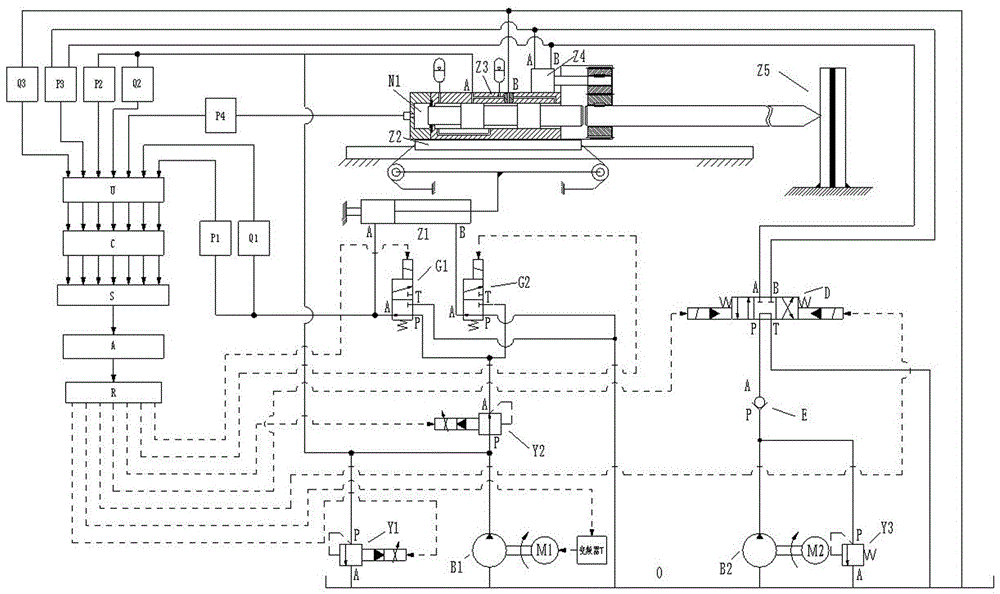

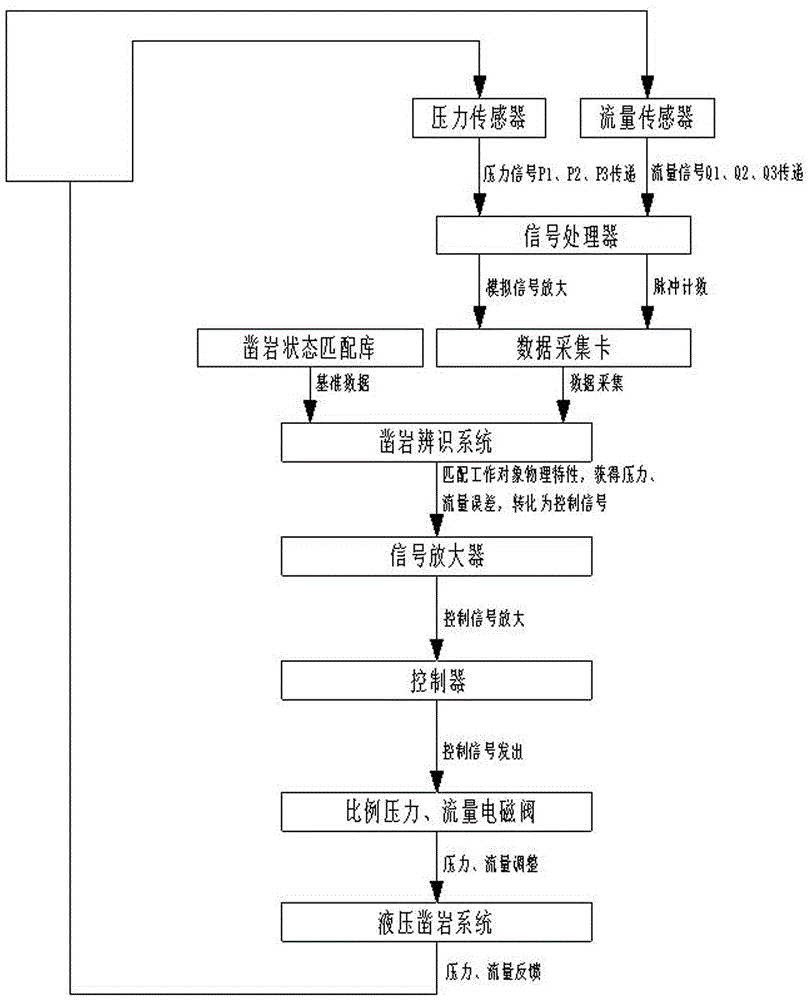

Hydraulic rock drill measuring and controlling system

InactiveCN107060727APressure real-time monitoringStable working parametersAutomatic control for drillingHydraulic cylinderAudio power amplifier

The invention discloses a hydraulic rock drill measuring and controlling system which comprises a power mechanism, an executing mechanism, an overflow valve, a rock drilling control valve and an electrical system. The power mechanism comprises a unidirectional pump for supplying oil to a hydraulic system. The executing mechanism comprises a propulsion hydraulic cylinder, a rock drilling machine and a rotary borer motor. The overflow valve comprises a guiding type proportional overflow valve body and an overflow valve body. The rock drilling machine control valve comprises a guiding type proportional pressure-reducing valve body, a high-speed on-off valve body, a guiding type solenoid directional valve body and a one-way valve body. The measuring and controlling system comprises four pressure sensors, three flow sensors, an amplifier, a datum acquisition machine card, a rock drilling state identification system and a controller. The working state of the hydraulic rock drilling machine is matched through the electrical system and compared with a corresponding normal rock-drilling state, and the errors of working parameters of the system are obtained and corrected. According to the hydraulic rock drill measuring and controlling system, real-time monitoring and control over the hydraulic rock drilling machine can be realized through the measuring and controlling system, so that the working state of the rock drilling machine is kept in the efficient rock drilling state in the process of rock-drilling propulsion.

Owner:GUILIN UNIV OF AEROSPACE TECH

Hydraulic-rock-drill measurement and control system

InactiveCN106150474APressure real-time monitoringStable working parametersAutomatic control for drillingData acquisitionEngineering

The invention discloses a hydraulic-rock-drill measurement and control system. The hydraulic-rock-drill measurement and control system comprises a power mechanism, an actuating mechanism, an overflow valve, a rock drilling control valve and an electrical system. The power mechanism comprises a one-way pump for supplying oil to a hydraulic system. The actuating mechanism comprises a boosting hydraulic cylinder, a rock drill and a rotation motor. The overflow valve comprises a pilot-type proportional overflow valve and an overflow valve body; a hydraulic-rock-drill control valve comprises a pilot proportional pressure reducing valve, a high-speed switch valve, a pilot-type electromagnetic directional valve and a one-way valve; the measurement and control system comprises four pressure sensors, three flow sensors, an amplifier, a data collection machine card, a rock-drilling-state identification system and a controller. The working state of a hydraulic rock drill is matched through the electrical system, and is compared with the corresponding normal rock drilling state, and the errors of working parameters of the system are obtained and corrected. According to the hydraulic-rock-drill measurement and control system, real-time monitoring and control of the hydraulic rock drill can be achieved through the measurement and control system, the working state of the rock drill is kept in the efficient rock drilling state in the rock drilling boosting process.

Owner:GUILIN UNIV OF AEROSPACE TECH

Dual shaft-well drill

InactiveCN101769127AReduce labor intensityShift quicklyDerricks/mastsDrilling machines and methodsWell drillingRock cutting

The invention relates to a dual shaft-well drill which comprises two drilling rigs, a connection mechanism for connecting the two drilling rigs, a rock drilling mechanism and a hydraulic and air supply system connected with each drilling rig. The drilling rig comprises an upright column, a swing frame movably mounted on the upright column, a movable arm with one end mounted on the swing frame and the other end mounted on the rock drilling mechanism, and a support arm with one end mounted on the upright column; the rock drilling mechanism comprises a sliding frame, a compensation frame mounted on the sliding frame, a rock driller mounted on the sliding frame, and a drilling tool mounted on the rock driller. During operation, the two drilling rigs are in rigid connection with each other, and then the support arm of each drilling rig extends out to support the shaft wall and ensures the drilling rigs to be stabilized in the well, the rock drilling mechanism moves to the drill pore position in translation manner along with the movable arms and is driven by the auxiliary hydraulic system and air supply to drill rock. The dual shaft-well drill has the advantages that: the construction demands of large diameter shaft well are met, the moving speed is high, the productivity is high and the work intensity is greatly reduced for workers.

Owner:ZHANGJIAKOU XUANHUA HUATAI MINING & METALLURGIC MACHINERY +1

Transition connection mining technique from outdoor mine to underground mine

ActiveCN103790589BImprove rock drilling efficiencyIncrease production capacityUnderground miningSurface miningTransition stagePunching

The invention discloses a transition connection mining technique from outdoor mine to underground mine. A transition stage(2) from outdoor mining to underground mining is divided into a connection production middle section (4) and an emergency middle section (5); in the emergency middle section (5), mine chambers (13) and mine columns are divided, and the mine chambers (13) are firstly recovered by utilizing an open-stope method; in the mine chambers (13), upward drainage ventilation holes (12) are dug to be communicated with the connection production middle section (4); an enclosed waterproof door (11) is installed in a development drift (16) in the emergency middle section; a VCR (vertical crater retreat) method is adopted for mining by drilling rocks through an outdoor punching device (6) and discharging ores through an underground bottom structure; a drainage well (14) is drilled between a blind oblique well (10) and the waterproof door (11) and is communicated with the middle section of a main water bin; water accumulated in the mine chambers (13) is pumped and exhausted to the ground surface by a water pump in the main water bin, and the mine columns are recovered; then the underground mining stage (3) is transited. According to the invention, the safe and stable transition from outdoor mining to underground mining is realized, and the problems of underground sudden inflow of water threat, great damage of the preserved mine columns and difficulty in recycling at the rear stage are solved.

Owner:SINOSTEEL MAANSHAN INST OF MINING RES

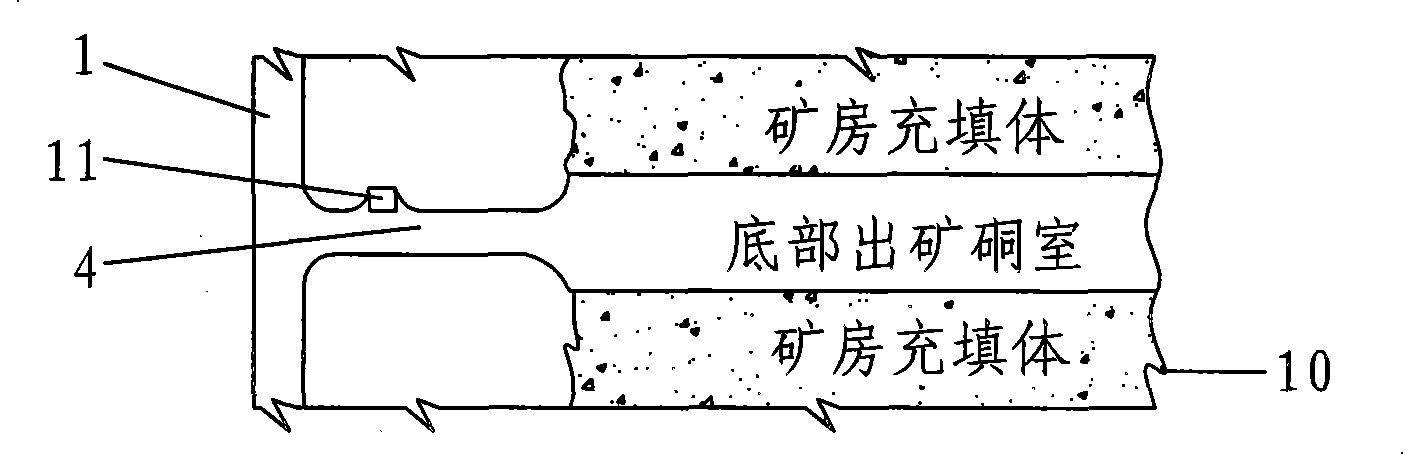

Non-bottom pillar deep hole falling-back type mining method

The invention relates to a non-pillar deep-hole backing-type mining method. The method is suitable for that: the digging height is between 10 and 50 m; the length of a stope is between 40 and 80 m; the width of the stope is between 7 and 9 m; the dip angle of an ore body is between 68 and 90 degrees; the height of a bottom ore removal chamber is between 2.5 and 3.5 m; the height of an upper part rock drilling chamber is between 3.4 and 3.8 m; meanwhile, an explosive charge structure, an explosion initiating sequence, stope side lacing and top plate control are determined according to the conditions of the stope, and a remote-control scraper and a remote-control crushing trolley are jointly used to treat large ore materials for ore removal. The mining method has the advantages of small mining-cutting engineering quantity, simple mining-cutting process, high rock drilling efficiency, good blasting effect, safe and efficient ore removal process, can effectively improve the wide-spacing stoping safety for underground metal mines nationwide, can upgrade the mining technical level for the underground metal mines in China, can promote the development of nationwide underground metal mine mining technology, and can reduce the dilution rate and loss rate of nationwide underground metal mine spacing stoping stopes, so as to promote the maximal recycling of metal resources.

Owner:深圳市中金岭南有色金属股份有限公司凡口铅锌矿

Novel pure-electric rock drill

InactiveCN105415293AEliminate dependenciesImprove rock drilling efficiencyPortable percussive toolsDrill bitGeotechnical engineering

The invention discloses a novel pure-electric rock drill. The novel pure-electric rock drill comprises a drill bit connection board, a storage battery case, a handle connection board and a drill body. The storage battery case is fixedly mounted on the top of the drill body. A storage battery is arranged in the storage battery case. The handle connection board is welded to the rear end of the drill body. Outward-stretching rods are fixed to the two sides of the drill body. A drill bit is mounted in a threaded groove in the front end of the drill bit connection board. Front buffer boards are welded to the two sides of the top of the drill body and fixedly provided with buffer springs respectively and correspondingly. The other ends of the buffer springs on the two sides are fixed to a spring connection board which is fixed to the top of the drill body. A socket is mounted at the rear end of the top of the drill body and connected with the storage battery case through a wire. Side boards are mounted on the outward-stretching rods on the two sides correspondingly. The other ends of the side boards are fixed to two ends of a handle. Rubber covers are mounted on the two sides of the handle. The novel pure-electric rock drill has the beneficial effects that by means of the storage battery type pure-electric rock drill, dependence on a transformer case is eliminated, and the rock drilling efficiency is improved in cooperation with a series of buffering and damping mechanisms.

Owner:CHONGQING YONGZHONG HEAVY IND

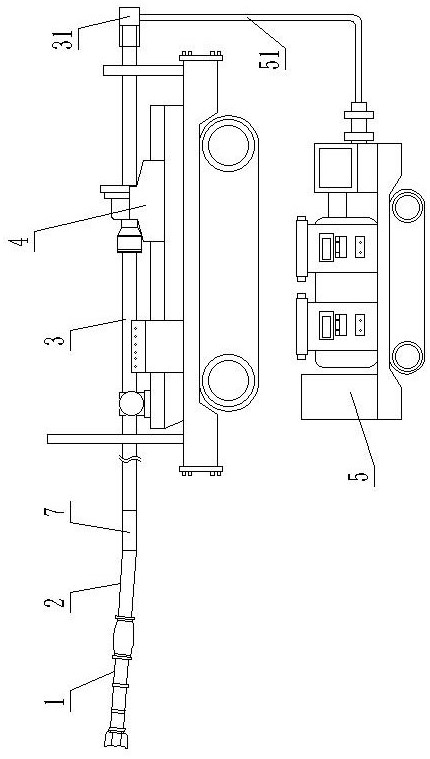

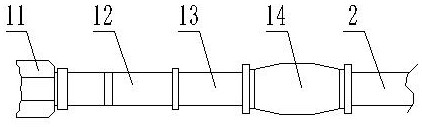

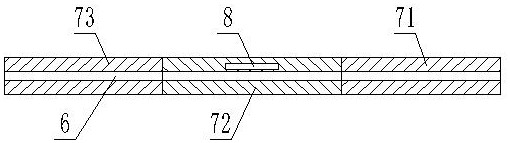

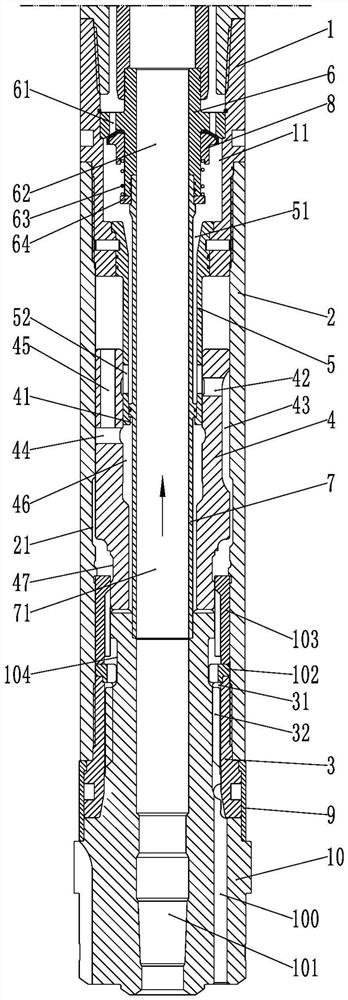

Directional impact rock hole construction equipment

PendingCN114382406AImprove rock drilling efficiencyTimely detection of deviationsSurveyDirectional drillingLine tubingRock cutting

The invention belongs to the technical field of rock hole construction, and particularly relates to directional impact rock hole construction equipment which comprises an impact assembly, an angle drill rod, a common drill rod, a directional drilling machine and a slurry pump truck, the impact assembly comprises a drill bit, a hydraulic impactor, a rotating shaft and a hole bottom pump, the rotating shaft is connected with the hole bottom pump, and the hole bottom pump drives the rotating shaft to rotate; one end of the hydraulic impactor is connected with the rotating shaft, the other end of the hydraulic impactor is provided with a drill bit, the end, away from the rotating shaft, of the hole bottom pump is connected with the angle drill rod, the angle drill rod is connected with the directional drilling machine through the common drill rod, the tail end of the common drill rod is provided with the water feeder, and the slurry pump truck is connected with the water feeder through a high-pressure pipeline. The impact assembly is arranged, and compared with the prior art that a rock drilling machine only has a drilling mode, the hydraulic impactor adopts the rock drilling machine in an impact mode, the drill bit arranged at the end of the hydraulic impactor adopts the rock drilling machine in the impact mode, and the rock drilling efficiency is higher.

Owner:SHANXI KAIYUAN YITONG MINING EQUIP MFG CO LTD

Novel down-the-hole sampling coring pneumatic percussion drilling tool

PendingCN112177520AImprove economyReduce consumptionBorehole drivesCore removalInlet channelRock cutting

The invention discloses a novel down-the-hole sampling coring pneumatic percussion drilling tool. The novel down-the-hole sampling coring pneumatic percussion drilling tool comprises a connector connected with one end of an outer cylinder, the other end of the outer cylinder is connected with a drive chuck, the tail end of a center drill bit is slidably connected into the drive chuck, a drill bitvent hole and a drill bit center hole are formed in the center drill bit, a limiting mechanism is arranged at the sliding connection position between the drive chuck and the tail end of the center drill bit and moves by a step pitch, a piston center hole, a piston first radial through hole, a piston large-diameter tangential section, a piston second radial through hole, a piston axial through holeand a piston inner circumferential annular groove are formed in a piston, the tail end of a gas distribution pipe is in communication with the connector, a gas distribution pipe radial through hole is formed in the head end of the gas distribution pipe, a gas distribution seat gas inlet channel and a gas distribution seat center hole are formed in a gas distribution seat in a penetrating manner,reciprocating switching impact is realized through selective connection of the holes, and the head end of a collecting pipe is inserted into the tail end of the drill bit center hole for coring. The drilling tool can meet the requirements for efficient rock drilling and convenient coring, and the integration level is high.

Owner:HUNAN XINJINGANG MACHINERY EQUIP

Automatic rollback control system and method for rock drill

ActiveCN106761660ATroubleshoot damage, etc.Avoid damageServomotor componentsAutomatic control for drillingAutomatic train controlSolenoid valve

The invention relates to an automatic rollback control system and method for a rock drill. The system comprises an electrical system, a hydraulic control handle, a control valve block, a pushing oil cylinder, a first pressure switch and an oil tank, and the control valve block comprises an automatic rollback control valve group, a hydraulic-control proportional multiway valve, an overflow valve, a throttle valve and a travel control valve; the automatic rollback control valve group comprises a reversing solenoid valve group and a second pressure switch; when the rock drill moves to the top end of a push beam, a stroke valve is touched, the pressure switches act and send out signals, the rock drill stops drilling automatically and retreats to a specified location, and in the retreating process, if the rock drill needs to move forwards, a person only needs to operate the handle again. Accordingly, the phenomena that when the rock drill drills into the top end of the push beam, the push beam is damaged, and the rock drill idles can be avoided, it can be guaranteed that the rock drill is in a controllable state in the automatic retreating process, operation is convenient, use is safe and reliable, and the efficiency is high.

Owner:CHINA RAILWAY ENGINEERING EQUIPMENT GROUP CO LTD

Automatic rock drilling device special for tunnel excavation

The invention relates to an automatic rock drilling device special for tunnel excavation, which has high rock drilling efficiency, is safe for using and contributes to saving time and construction cost. The automatic rock drilling device comprises a control stand, a support frame, a power device, a movable carrier and rock drilling equipment, wherein the support frame is arranged on the carrier; the power device, the control stand and the rock drilling equipment are arranged on the support frame; the power device is connected with the rock drilling equipment through a lead; the control stand is connected with the power device and the rock drilling equipment through leads respectively; the support frame is a square frame body; the support frame body is provided with at least one group of platforms capable of extending and contracting towards both sides; the rock drilling equipment comprises one or more groups of mechanical arms and drill bits arranged on the mechanical arms; one end of each mechanical arm is connected to the frame body; and the other end of each mechanical arm is provided with a drill bit. The automatic rock drilling device has the advantages of high rock drilling efficiency, use safety, saving in time and construction cost, and the like.

Owner:游天义

A wind-water linkage device for a hydraulic rock drill

The invention relates to a wind-water linkage device for a hydraulic rock drill, which includes an air pipe, a water pipe, and a communication pipe; the air pipe and the water pipe are connected through the communication pipe, and a check valve is provided at the end of the communication pipe close to the air pipe. One end close to the water pipe is provided with a first ball valve; the outlet of the air pipe is connected with the head of the hydraulic rock drill, and the outlet of the water pipe is connected with the drill bit of the hydraulic rock drill; Improve the structure of the wind pipe and water pipe to connect the air and water, use the combined effect of wind and water to clean the drill pipe in time, remove rock dust, improve rock drilling efficiency, and at the same time greatly reduce the wear of drill rods and drill bits , improve equipment utilization efficiency, and ultimately ensure construction efficiency.

Owner:JCHX MINING MANAGEMENT

Cluster type down-the-hole hammer

PendingCN113431485AImprove rock drilling efficiencyReduce energy consumptionBorehole drivesWell/borehole valve arrangementsInlet channelRock cutting

The invention discloses a cluster type down-the-hole hammer. The cluster type down-the-hole hammer comprises a drill rod and a down-the-hole hammer connected with the drill rod, a main air inlet channel is formed in the drill rod, a high-pressure air chamber communicated with the main air inlet channel is arranged on the down-the-hole hammer, an airflow adjusting valve with a valve block and an airflow adjusting hole is arranged between the drill rod and the down-the-hole hammer, and the airflow adjusting hole is closed by the valve block. An air inlet of the airflow adjusting valve communicates with the main air inlet channel, an air outlet of the airflow adjusting valve communicates with the high-pressure air chamber, a flow dividing air chamber is arranged on the down-the-hole hammer, and the opening degree of the valve block on the airflow adjusting hole is adjusted, so that high-pressure air in the main air inlet channel is divided into the flow dividing air chamber. According to the cluster type down-the-hole hammer, when the cluster down-the-hole hammer performs drilling and rock drilling operation in different stratums, air flow can be adjusted in time, so that the rock drilling efficiency is improved, and energy consumption is reduced. The whole linkage structure in the airflow adjusting valve is convenient to assemble and disassemble, a corresponding exhaust channel is arranged only by means of the structure of a down-the-hole hammer shell, no part needs to be additionally arranged, and structural design is reasonable and compact.

Owner:NANJING VOCATIONAL UNIV OF IND TECH +1

Efficient type rock drilling equipment used for ore extraction

InactiveCN111236832AIncrease impactEasy to chisel outReciprocating drilling machinesConstructionsMining engineeringRock cutting

The invention relates to efficient type rock drilling equipment used for ore extraction. The efficient type rock drilling equipment comprises a handle, a housing, a rock drilling mechanism and a plurality of fastening mechanisms, wherein the rock drilling mechanism comprises a fixed plate, a rotary assembly, a rotary shaft, a power supply, an electromagnet, an extrusion board, a magnetic board, abore bit, a plurality of first springs, two conductive assemblies and two connecting assemblies, each fastening mechanism comprises a fastening tube, a telescopic assembly and a fastening assembly, the fastening assembly comprises an elastic pushing rod and a fastening board. According to the efficient type rock drilling equipment used for ore extraction disclosed by the invention, the equipment is conveniently fixed through the fastening mechanisms, so that rock drilling efficiency is prevented from being affected by deviation during rock drilling; moreover, the first springs and the electromagnet of the rock drilling mechanism are utilized to generate downward acting force on the magnetic plate, so that impact force, on a rock layer, of the bore bit is strengthened, drilling marks are conveniently drilled on a hard rock layer, and rock drilling efficiency is improved, and therefore, practicability of the equipment is improved.

Owner:SHENZHEN LVYUAN HUIZHI TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com