Hydraulic rock drill measuring and controlling system

A technology of hydraulic rock drill and measurement and control system, which is applied to the automatic control system of drilling, drilling equipment, earthwork drilling and production, etc. It can solve the complicated and difficult problems of the stability of the working state of hydraulic rock drill, and achieve the improvement of rock drilling efficiency and working parameters. maintain a stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below with reference to the accompanying drawings and examples.

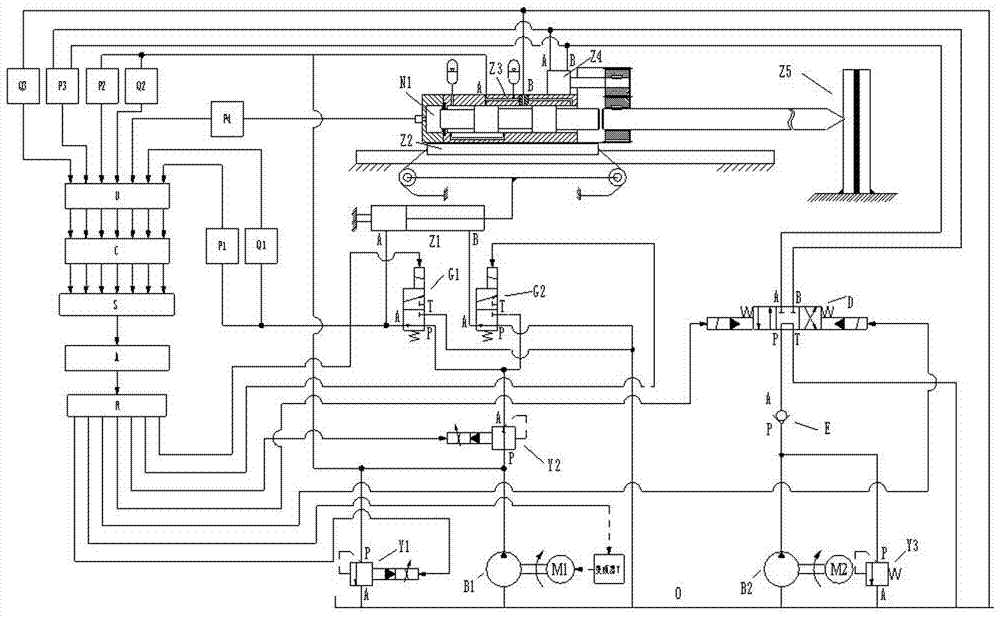

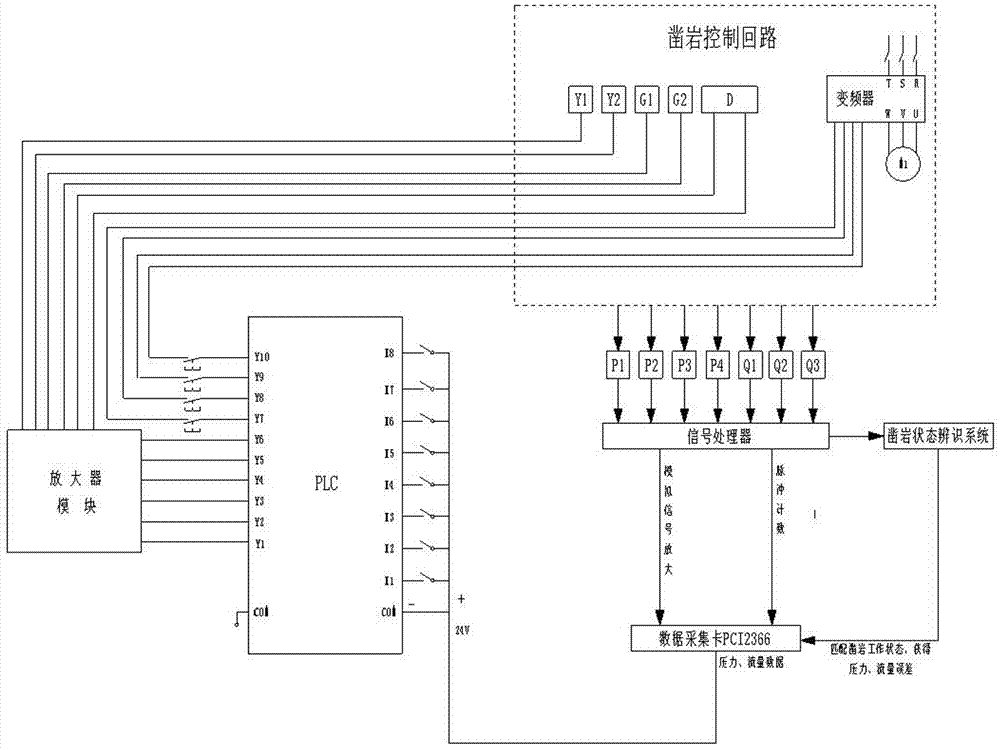

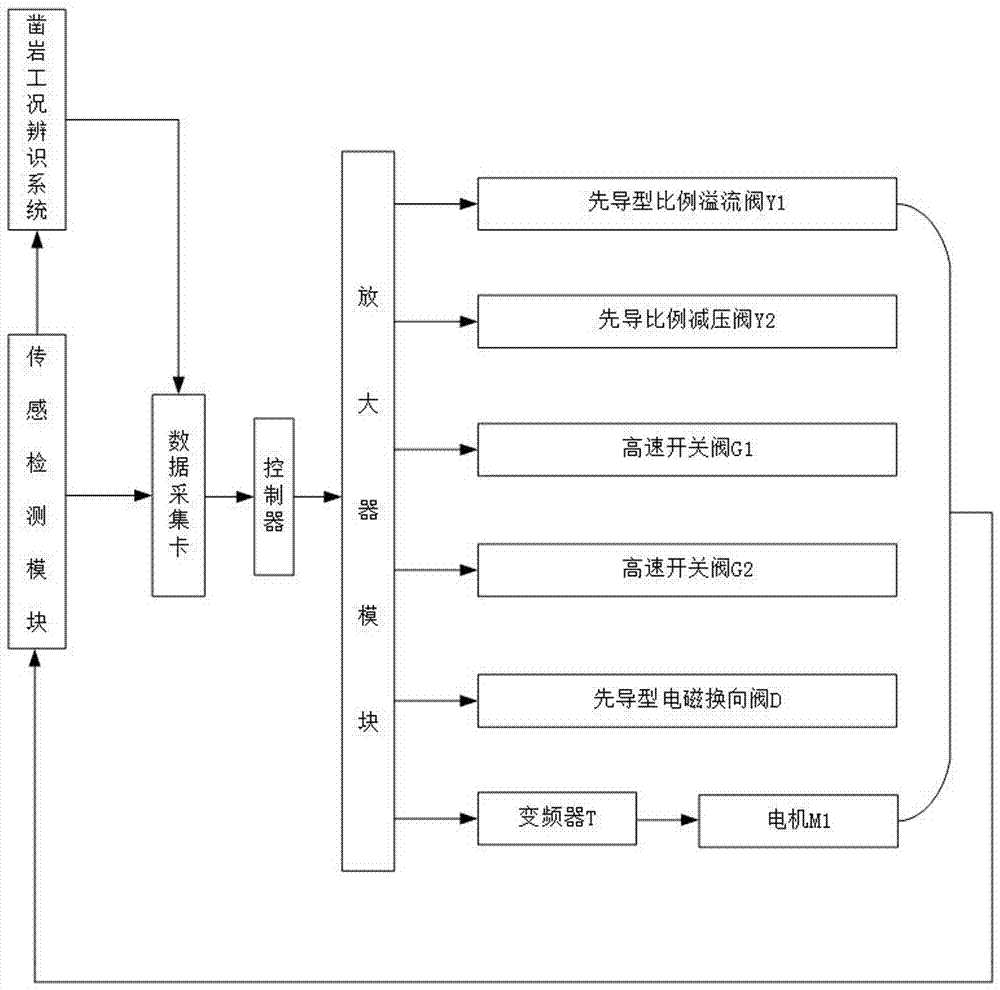

[0021] As shown in the accompanying drawing 1, a measurement and control system for identifying the working state of a hydraulic rock drill according to the present invention includes a power mechanism, an actuator, an overflow valve, a rock drilling control valve group, and a measurement and control system; wherein:

[0022] The power mechanism includes two one-way pumps B1 and B2. The one-way pump B1 is driven by a motor M1 equipped with a frequency converter T. Adjust the frequency converter T to change the speed of the motor M1, thereby changing the displacement of the pump B1 to change the speed of the load. The identification result of the working state of the measurement and control system makes R feedback to control the frequency converter T; the one-way pump B2 is driven by the motor M2 to provide the required pressure oil.

[0023] The executive ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com