Modular full-hydraulic rock drilling system

A fully hydraulic and modular technology, applied in mining equipment, earthwork drilling, tunnels, etc., can solve problems such as poor safety, low operating efficiency, and high labor intensity, and achieve high operating safety, low labor intensity, and flexibility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

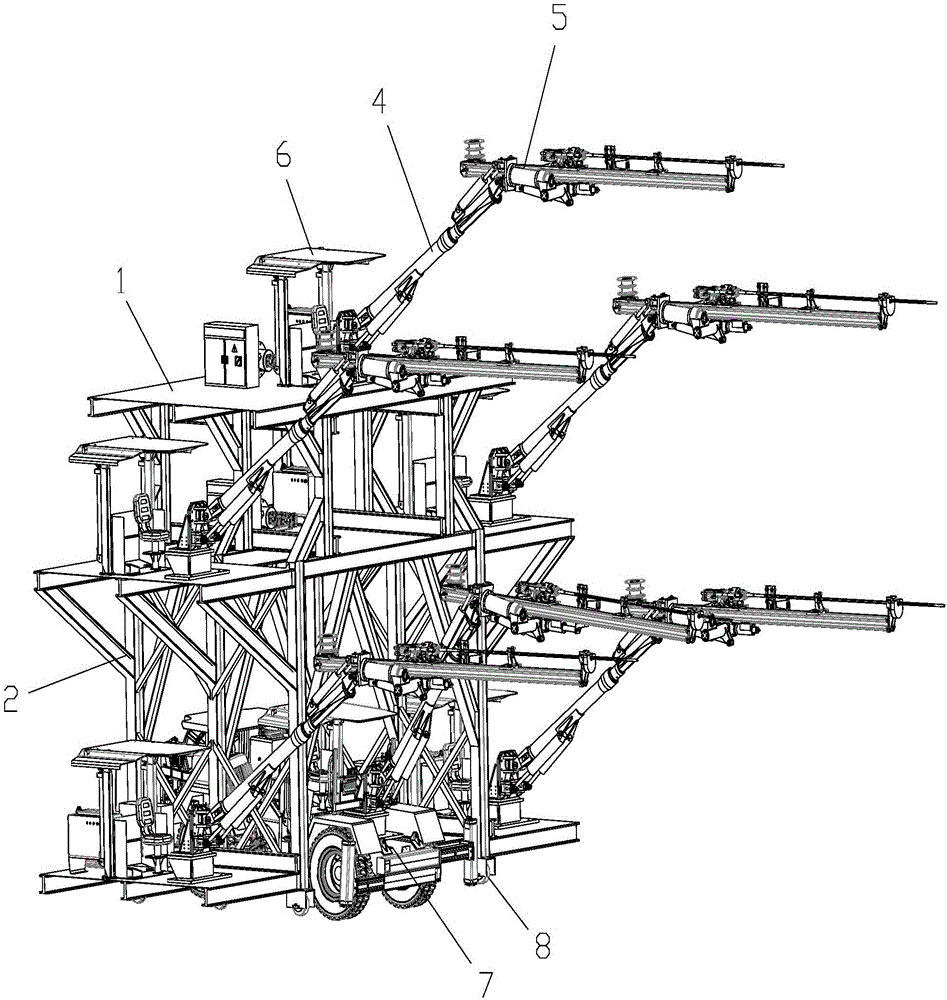

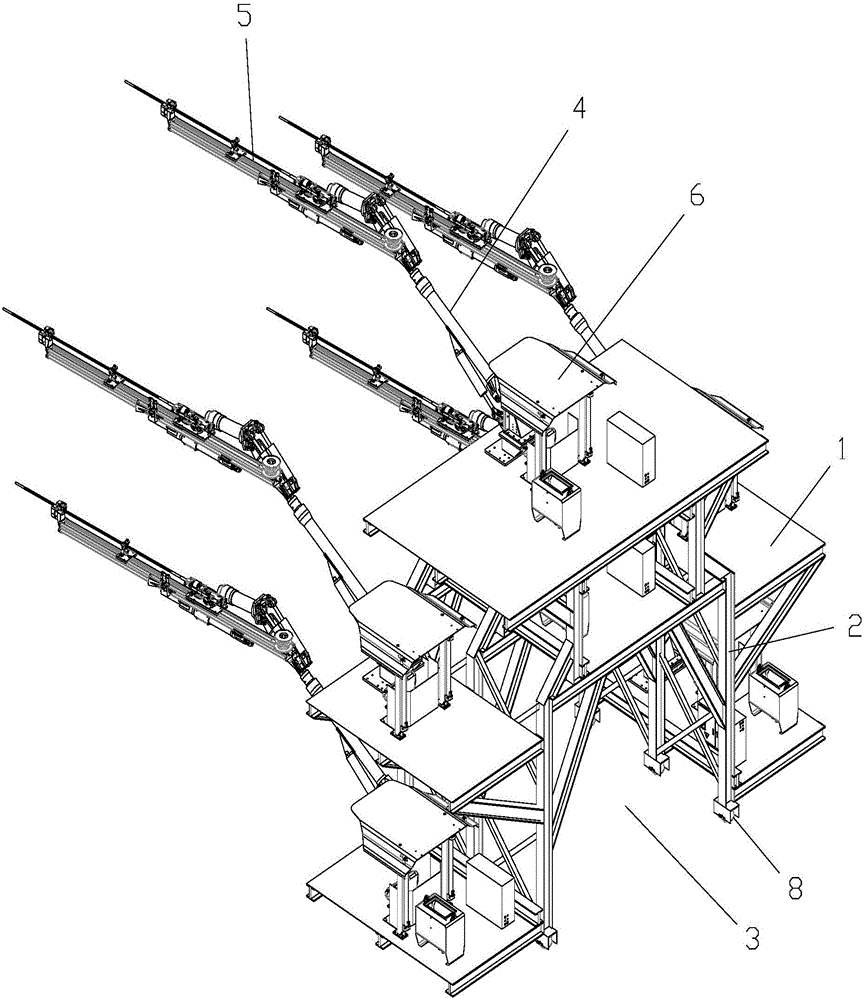

[0023] The modular full hydraulic rock drilling system of this embodiment includes a rock drilling platform, and the rock drilling platform includes a three-layer horizontal workbench 1 and a bracket 2 connecting the three-layer horizontal workbench, connecting the first layer of horizontal workbench and the second layer of horizontal workbench. The middle part of the support of the horizontal workbench on the second floor is provided with a door-shaped channel 3;

[0024] Also comprise the rock drilling device that is arranged on each layer of horizontal workbench, described rock drilling device comprises the rock drilling arm 4 that is connected on the horizontal workbench and the rock drilling machine 5 that is connected on the rock drilling arm;

[0025] It also includes a protective shed 6 arranged on each level of the horizontal workbench to prote...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com