Mining medium-length hole drilling and blasting method

A technology of deep holes and blastholes, which is applied in the field of deep hole rock drilling and blasting in mining, can solve the problems of high cost of rock drilling and blasting, and difficulty in adjusting the charge amount, so as to reduce the cost of rock drilling and blasting, reduce mining costs, Reduced the effect of blast shock waves and seismic waves

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

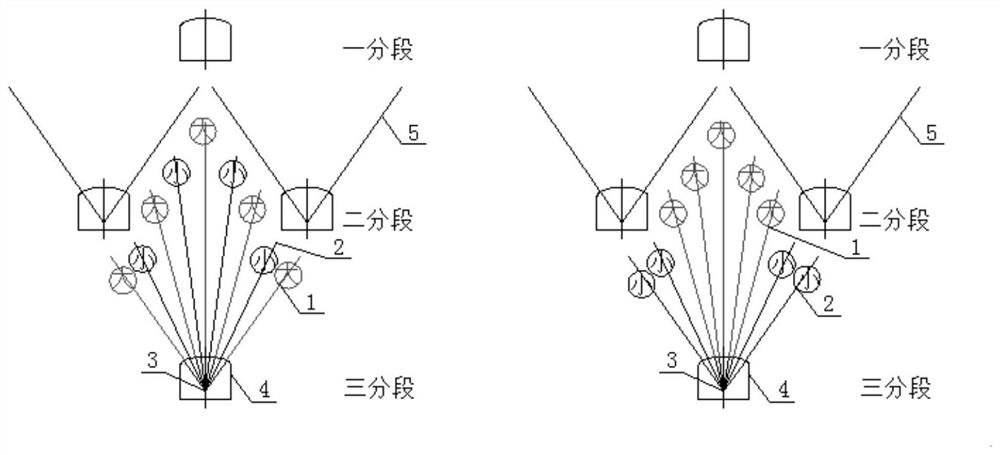

Embodiment 1

[0016] The northern ore body of Meishan Iron Mine is a branch of the main ore body. The ore body elevation is -89m. The mining method of ramp development and sub-column caving is adopted. The test block stope structure parameters at the end of the ore body are 16m×15m, the route section is 4.5m×3.8m, there are two kinds of parameters for mining medium and deep hole rock drilling blasting, among them: the blast hole diameter of the N6# and N7# recovery routes is φ78mm, the row spacing is 2.2m, the hole bottom The hole distance is 2.0~2.2m, the side hole angle is 55°, the blast hole diameter of N8# and N9# recovery approach is φ72mm, the row spacing is 2.0m, the hole bottom distance is 2.2~2.6m, and the side hole angle is 55°. The CTC-141 pneumatic rock drilling jumbo is equipped with the YG90 rock drill for mining medium and deep hole operations, and the BQF-100 chargeer is used for mining medium and deep hole charge operations.

[0017] According to the present invention, when...

Embodiment 2

[0019] Shilu Iron Mine is a large-scale open-pit-to-underground mine. It adopts the joint development of shafts and slopes, and the mining method of segmental caving without pillars. The stope structure parameters are 15m×18m, and the approach section is 4.5m×3.8m.- The parameters of deep hole rock drilling in 60m segmental mining are: blasthole diameter φ87mm, row spacing 2.2m, hole bottom distance 3.2~3.4m, side hole angle 50°, center of rotation (double center) height 1.85m , each row of 8 gun holes. The SimbaH1354 full-hydraulic rock drilling rig is used with the cop1838 rock drill for mining medium and deep hole operations, and the BQF-100 chargeer is used for mining medium and deep hole charge operations.

[0020] According to the invention, in the design of deep holes in mining, according to the requirements of the explosiveness of ore rock and the step distance of ore collapse, the blast hole diameters are φ87mm and φ78mm, and the blast hole row spacing=25~40×Blast hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com