Automatic rollback control system and method for rock drill

A technology of retreat control and rock drilling machine, which is applied to the automatic control system of drilling, earthwork drilling, mechanical equipment, etc. It can solve the problems of damaging the drill pipe and bit of the rock drilling machine, increasing construction costs, and air drilling of the rock drilling machine, etc., so as to prolong the service life , Guarantee the construction period and reduce the effect of labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

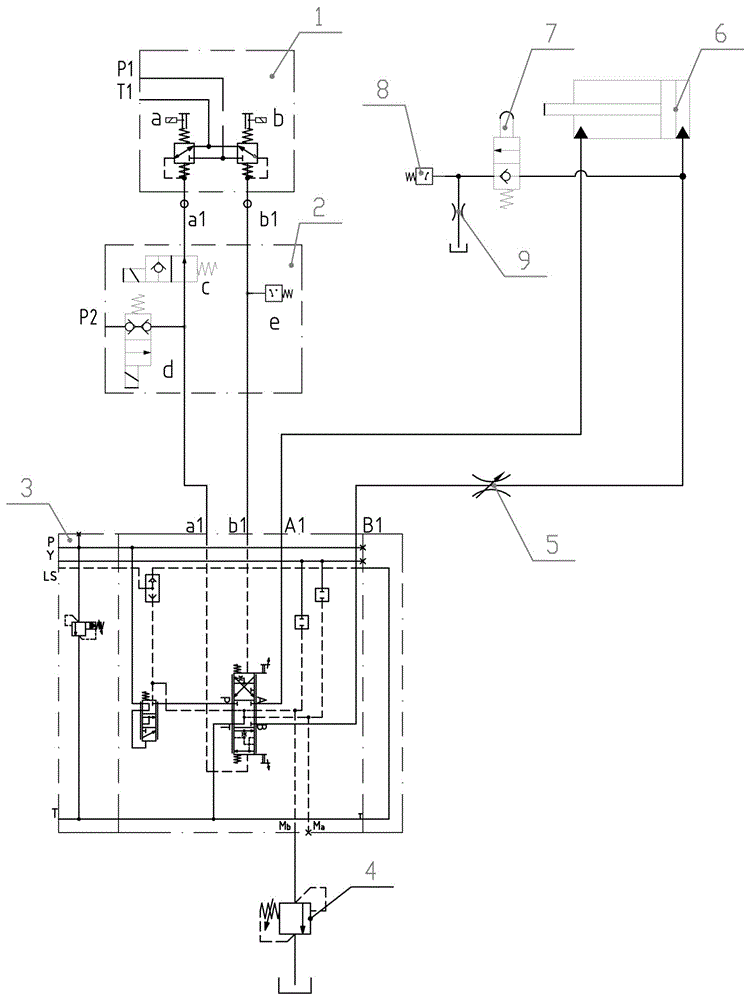

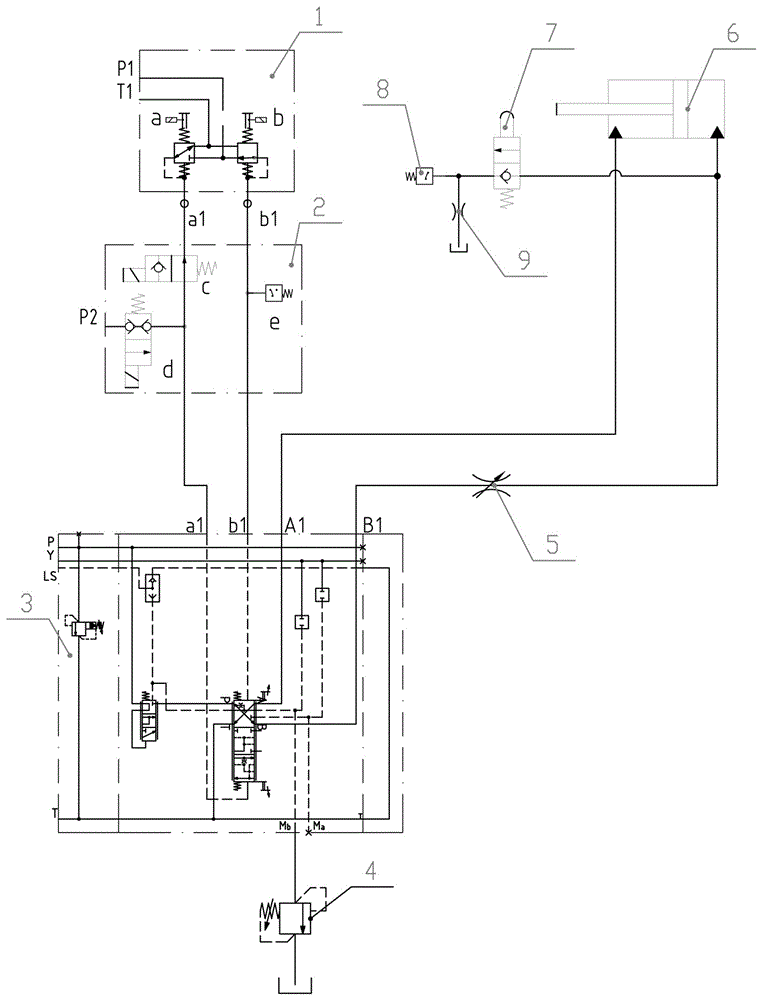

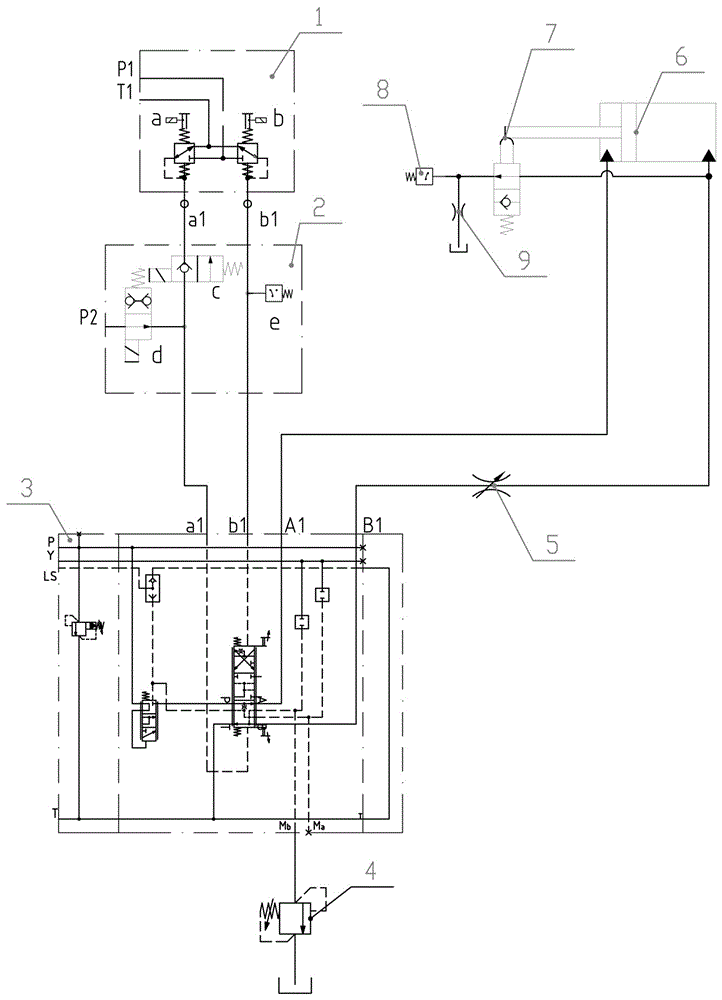

[0028] Embodiment one, see Figure 1~3 As shown, an automatic retreat control system for a rock drill includes an electrical system, a hydraulic control handle, a control valve block, a push cylinder, a pressure switch 1, an oil tank, and the control valve block and pressure switch 1 are respectively connected to the signal of the electrical system, and the control valve block It includes automatic retreat control valve group, hydraulic control proportional multi-way valve, relief valve, throttle valve and stroke control valve; the automatic retreat control valve group includes reversing solenoid valve group and pressure switch two; hydraulic control handle The oil circuit 1 of the hydraulic control handle is connected to the control oil circuit 1 of the hydraulic control proportional multi-way valve through the reversing solenoid valve group, and the oil circuit 2 of the hydraulic control handle is connected to the control oil circuit 2 of the hydraulic control proportional mu...

Embodiment 2

[0034] Embodiment 2, a rock drilling machine automatic retreat control method, implemented based on the rock drill automatic retreat control system described in Embodiment 1, the implementation process specifically includes the following content:

[0035] Step 1. Operate the hydraulic control handle, push the propulsion cylinder through the hydraulic control proportional multi-way valve, and the rock drill advances to the top of the propulsion beam;

[0036] Step 2. When the rock drill travels to the top of the propulsion beam, trigger the stroke control valve to change direction;

[0037] Step 3. Obtain a pressure signal from the pressure switch and compare it with the preset pressure until the preset pressure is met, control the hydraulic control handle to return to the neutral state, and trigger the reversing solenoid valve group to be energized to make it change direction. The oil cylinder controls the rock drill to enter the automatic retreat state;

[0038] Step 4. Dete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com