Anti-borer-clamping hydraulic control system and rock drilling equipment

A hydraulic control system and a technology for sticking drills, which are applied in the directions of fluid pressure actuating system components, mechanical equipment, fluid pressure actuating devices, etc., can solve the problems such as the inability to continuously control the propulsion pressure and impact power, and the inability to cope with the stuck drills in the karst cave. Achieve the effect of improving rock drilling efficiency and self-adaptive control stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

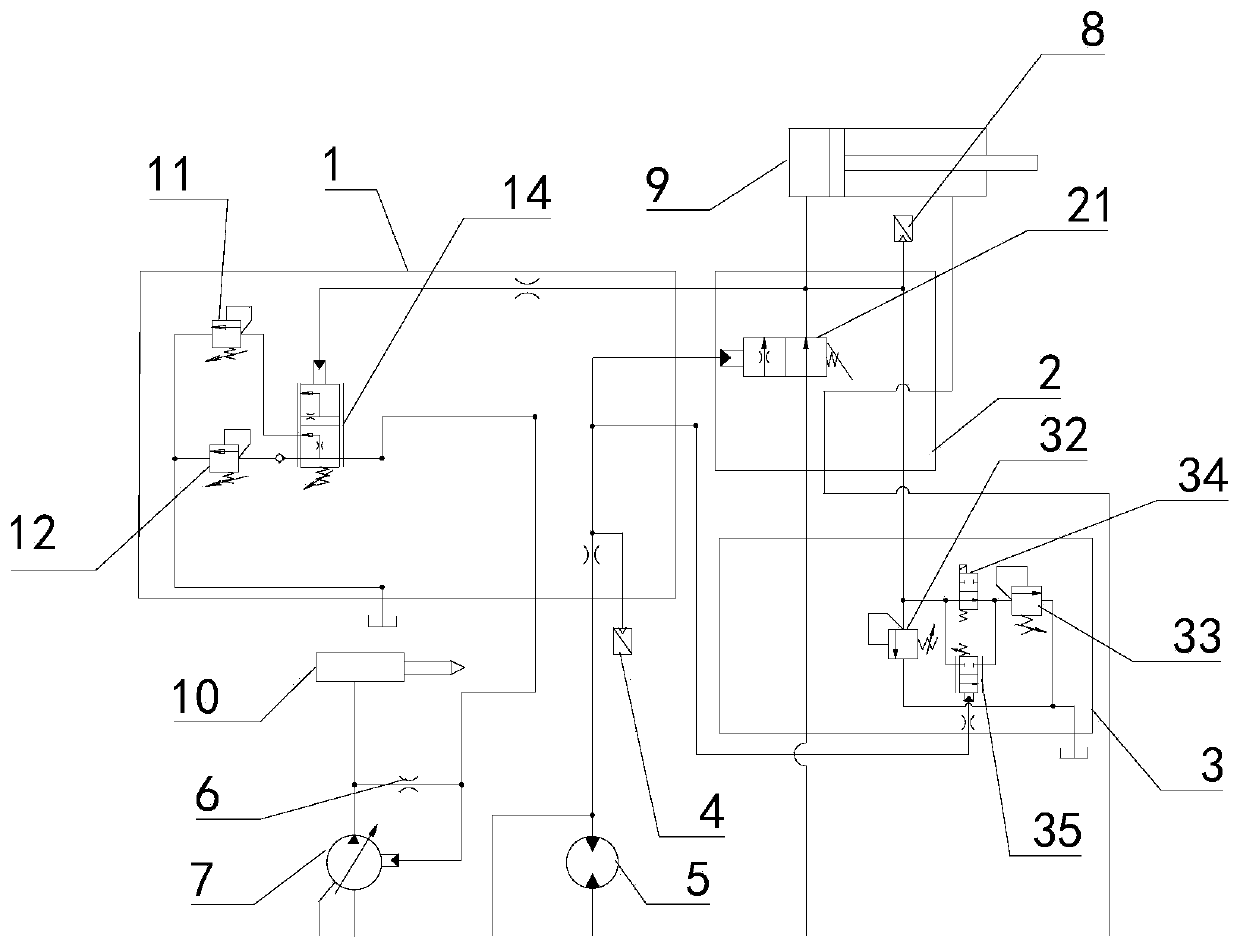

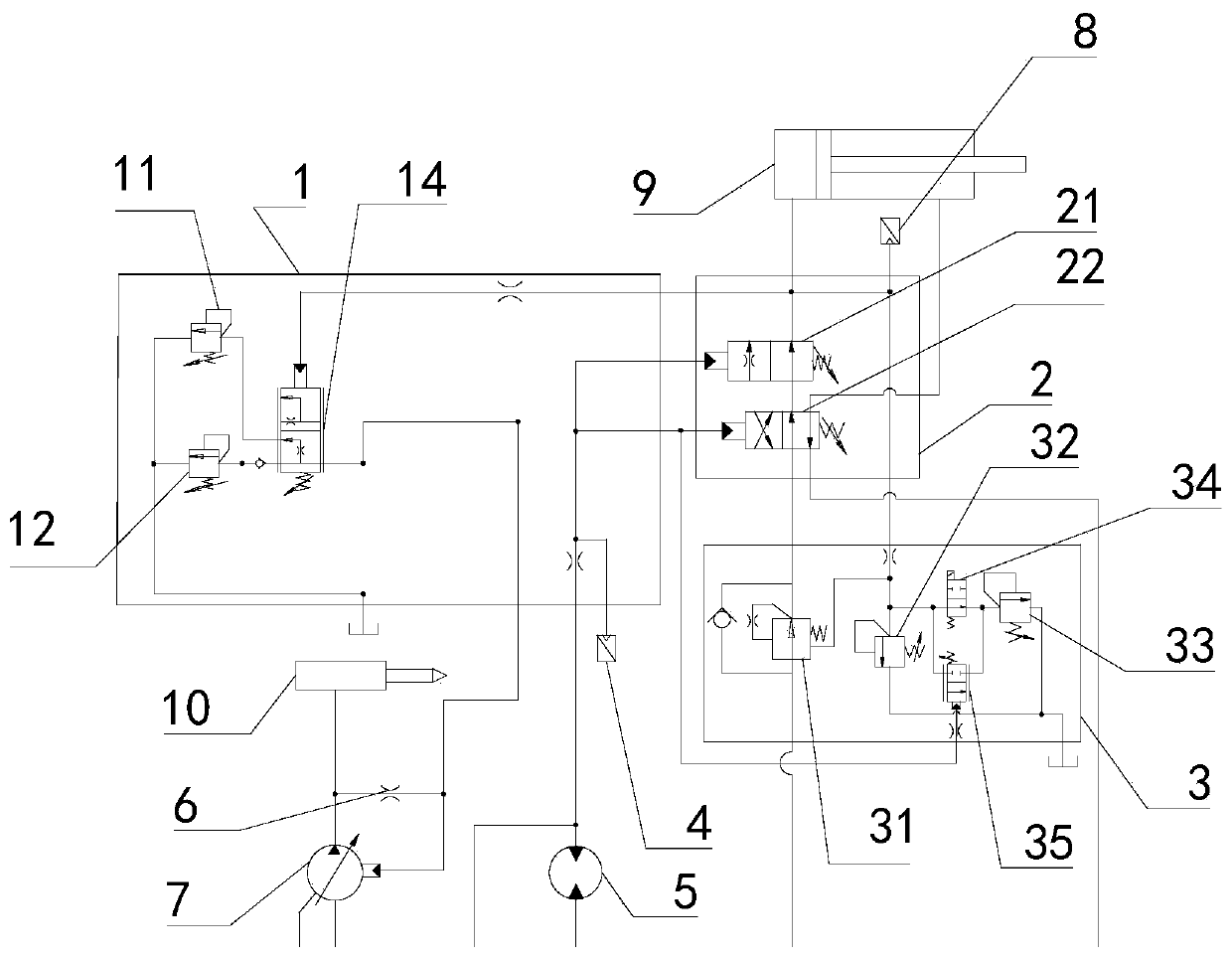

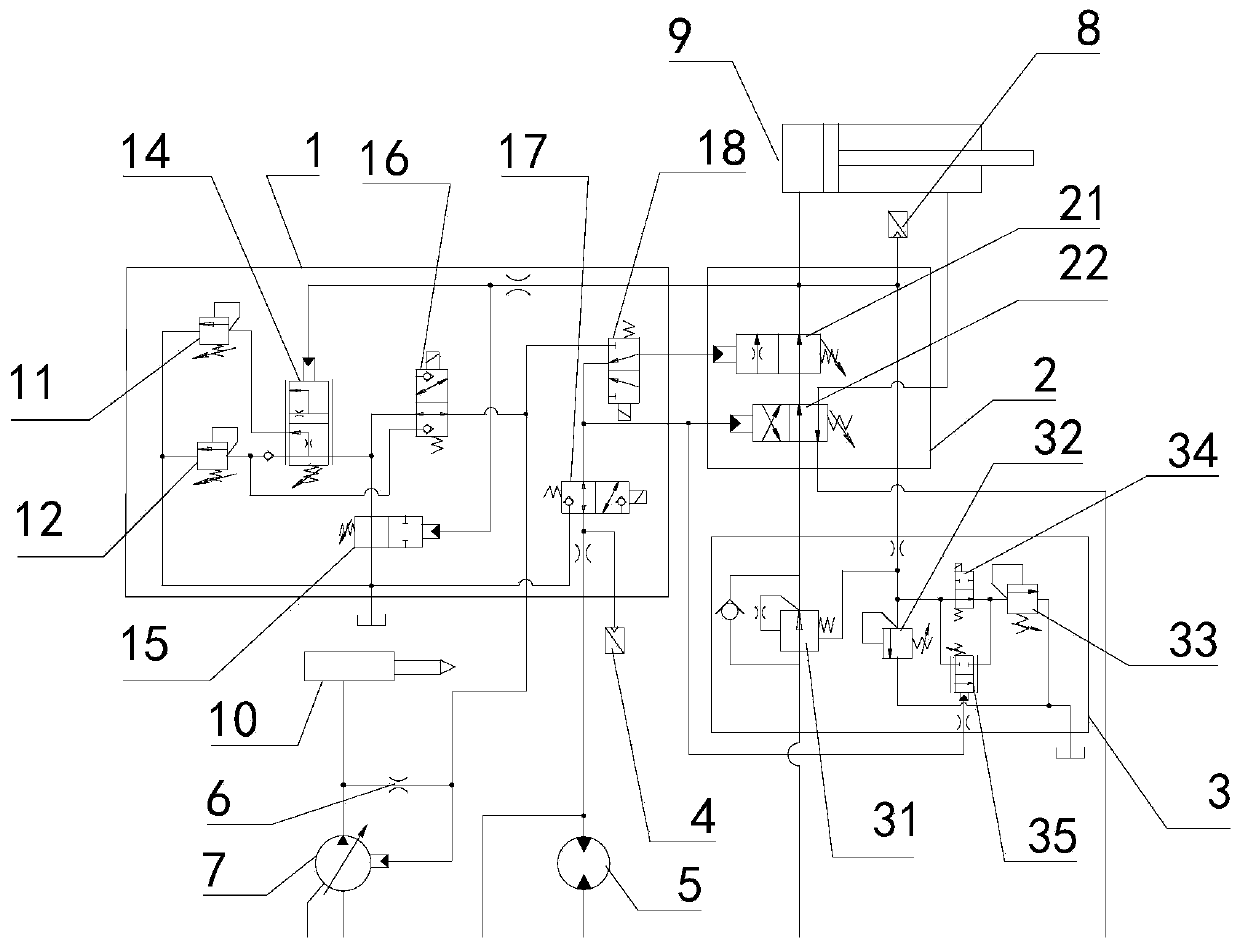

[0043] see Figure 1 to Figure 3 As shown, this embodiment provides an anti-jamming hydraulic control system; figure 1 The first structural schematic diagram of the anti-jamming hydraulic control system provided in this embodiment; figure 2 The second structural schematic diagram of the anti-jamming hydraulic control system provided in this embodiment; image 3 The third structural schematic diagram of the anti-jamming hydraulic control system provided in this embodiment.

[0044] The anti-jamming hydraulic equipment provided in this embodiment is used for rock drilling equipment.

[0045] see Figure 1 to Figure 3 As shown, the anti-jamming hydraulic control system includes an impact control module 1, a propulsion pressure control module 3, a propulsion speed control module 2, a variable pump 7, a rotary motor 5 and a propulsion cylinder 9; wherein the variable pump 7 is used to drive a rock drill 10 To impact the rock, the rotary motor 5 is used to drive the drill bit o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com