Method for forming covering layer by stope caving method

A technology for caving mining and overburden, applied in the field of underground mine mining, can solve the problems of high cost and low technical efficiency, and achieve the effects of large blasting block, reducing dilution loss and improving rock drilling efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

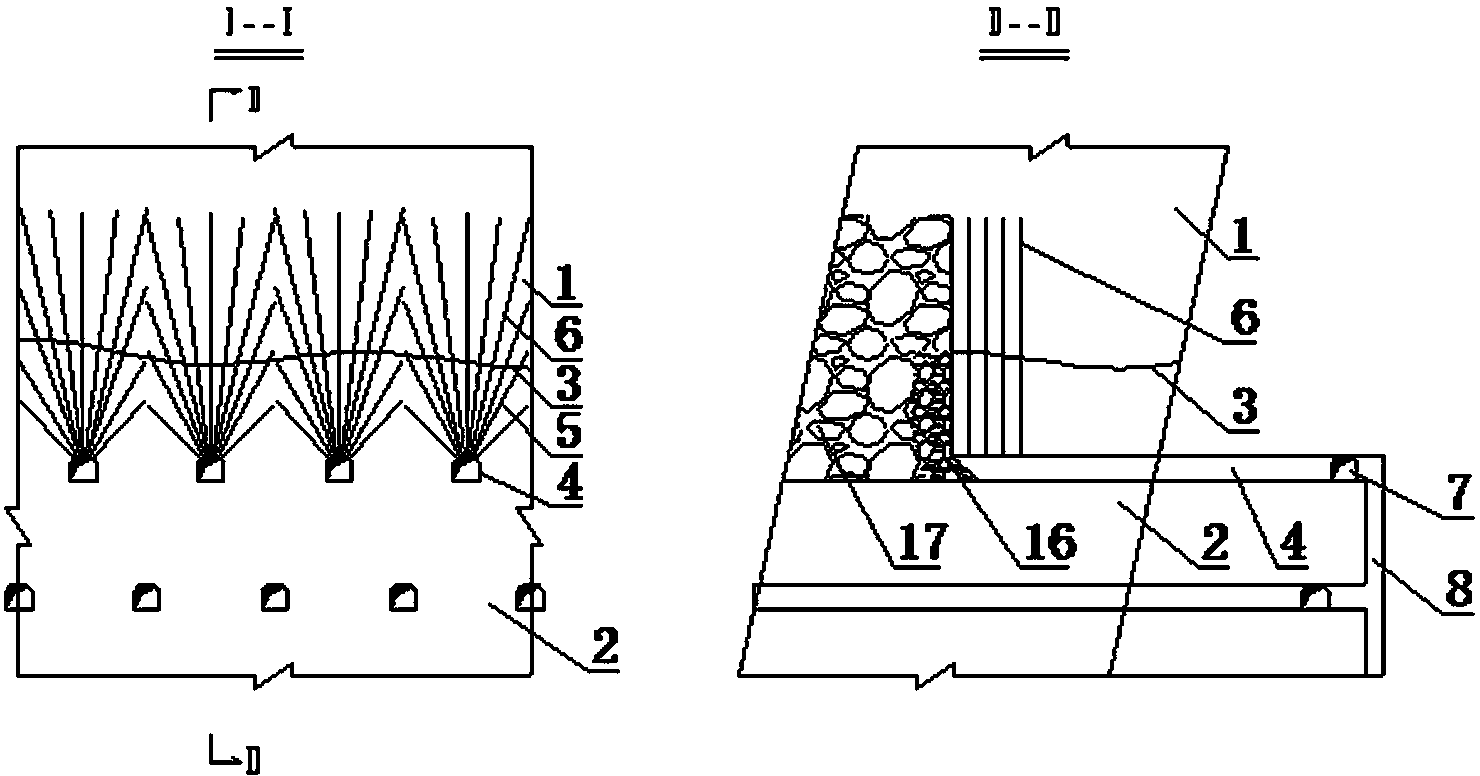

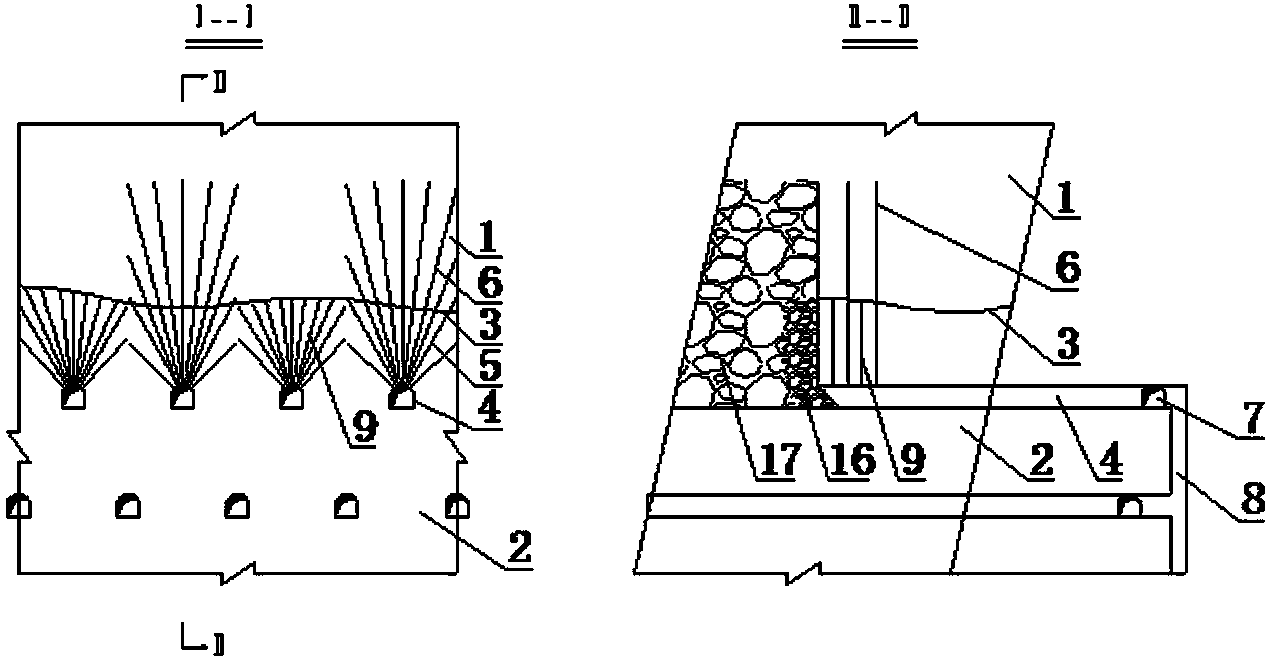

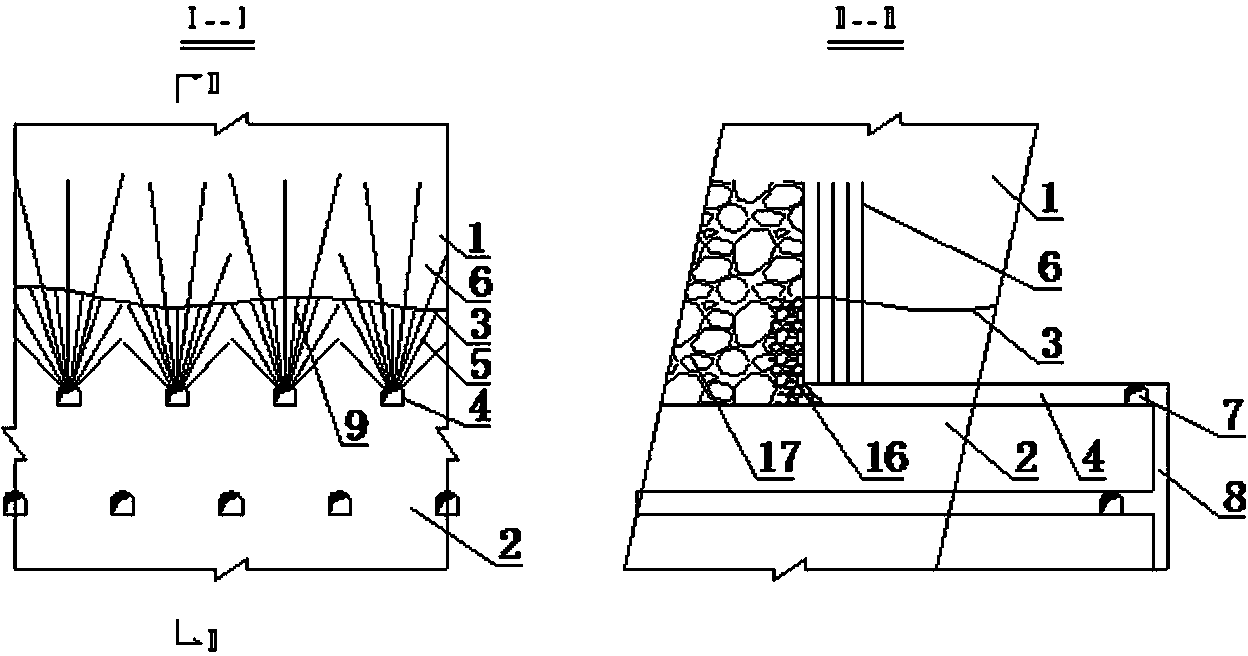

[0024] The following is a detailed description by taking the sub-level caving mining method without pillars as an example. Such as Figure 1~3 As shown, when the caving method is used for mining, the upper part is the top wall surrounding rock 1, and the lower part is the ore body 2, and the two are separated by the ore-rock boundary line 3. The mining roadway is arranged in the ore body, and its section height can be consistent with other section heights. Adopting the method for forming the covering layer of the present invention directly utilizes the rock drilling roadway required for mining in the first section to drill upward fan-shaped middle-deep holes, super-deep on the basis of mining blast holes, and blasts simultaneously with the mining in the first section.

[0025] The specific method is: drill upward fan-shaped blastholes 5 in the rock drilling roadway 4 of the first section, and part of the blastholes extend to the surrounding rock of the roof and exceed the bou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com