Method for achieving fine blasting by replacing vertical deep hole with downward fan-shaped deep hole

A fan-shaped deep hole and vertical deep hole technology, applied in the field of prospecting, can solve the problems of low drilling efficiency and slow speed, and achieve the effects of reducing the unit consumption of explosives, accurate charge amount, and optimizing blasting parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0041] The method for finely blasting downward fan-shaped deep holes instead of vertical deep holes is characterized in that it includes the following steps,

[0042] Step 1, back mining rock drilling:

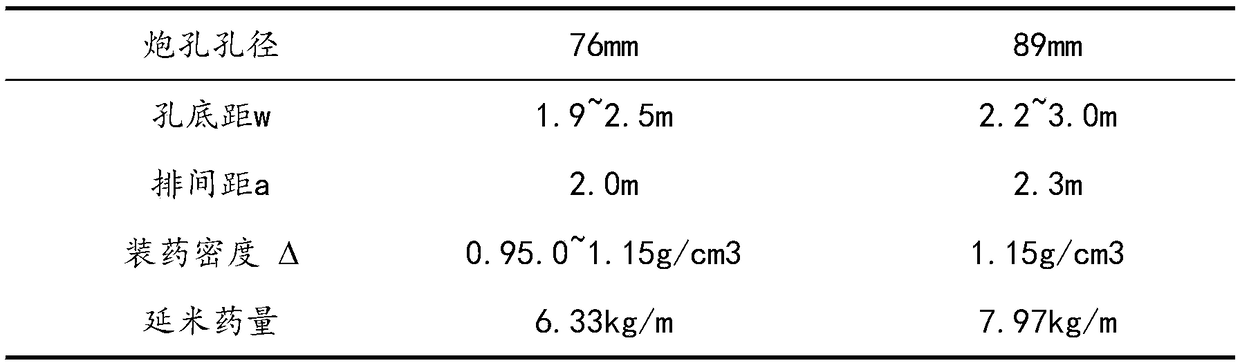

[0043] The mining method mainly adopts the mining method of large-diameter deep hole stage emptying and subsequent filling. The height of the mine room is 60m, the width is between 15-20m, and the length is the thickness of the ore body. Drill vertical deep holes downward in the rock drilling chamber of the stope. The diameter of the blast hole is Φ165mm, the depth of the blast hole is about 41m, the parameter of the hole network is 3m*3m, and the height of the bottom is 15m. 76mm, row distance 1.8-2m, hole bottom distance 2-2.5m;

[0044] Step 2, mining design optimization:

[0045] A rock-drilling roadway with a width*height of 5m*4m is designed at the horizontal boundary of the second-step mining house-390 as a rock-drilling chamber shared by the first-step mining and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com