Directional impact rock hole construction equipment

A technology for construction equipment and rock drilling, applied in drilling equipment and methods, directional drilling, drilling equipment, etc., can solve problems such as low efficiency, and achieve the effect of high rock drilling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Further description will be made below in conjunction with specific embodiments.

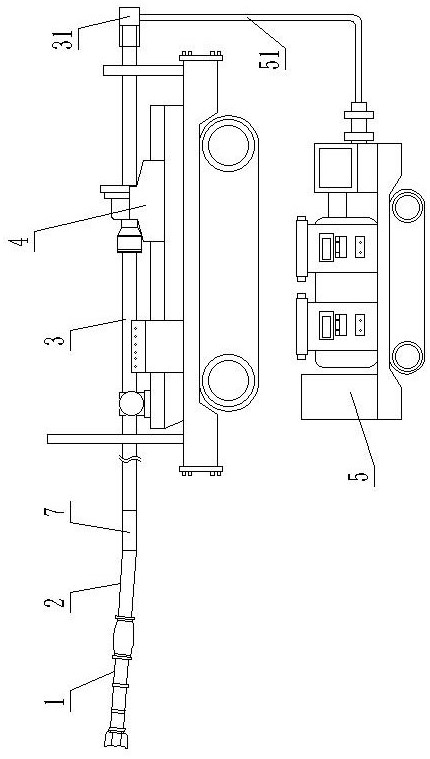

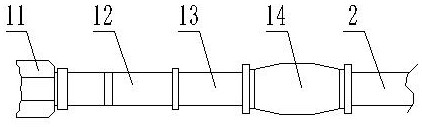

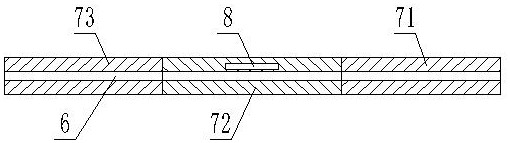

[0021] Such as figure 1 , figure 2 As shown, the directional impact rock hole construction equipment includes: an impact assembly 1, an angle drill pipe 2, an ordinary drill pipe 3, a directional drilling machine 4 and a mud pump truck 5, and the impact assembly 1 includes: a drill bit 11, a hydraulic impactor 12 , the rotary shaft 13 and the bottom hole pump 14, the rotary shaft 13 is connected with the bottom hole pump 14, the bottom hole pump 14 drives the rotary shaft 13 to rotate, and the bottom hole pump 14 drives the rotary shaft The working principle of 13 is similar to that of the hydraulic motor, one end of the hydraulic hammer 12 is connected to the rotary shaft 13, the other end of the hydraulic hammer 12 is provided with a drill bit 11, and the bottom hole pump 14 deviates from One end of the rotary shaft 13 is connected with the angle drill rod 2, and the angle drill rod ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com