Transition connection mining technique from outdoor mine to underground mine

A technology of converting from open-pit to underground and mining method, applied in the field of safe and efficient mining, can solve the problems of increasing ore loss and mining costs, reducing technical and economic indicators, etc., and achieve the effect of high rock drilling efficiency and large production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

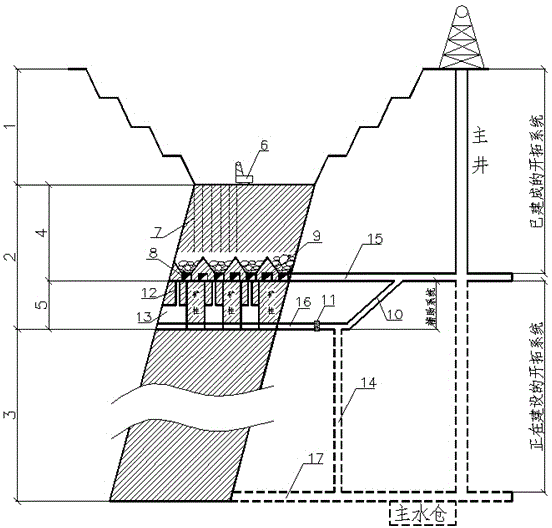

[0020] In order to further describe the present invention, a transition mining method of the present invention for transitioning from open-pit to underground mines will be further described in detail below in conjunction with the accompanying drawings.

[0021] Depend on figure 1 As can be seen from the schematic diagram of a transitional mining method for an open-pit to underground mine, the present invention divides the open-pit to underground mine into three stages: open-pit mining stage 1, open-pit to underground transition stage 2, and underground mining stage 3. In the transition stage from open-pit to underground, it is further divided into connecting production middle section 4 and emergency middle section 5. The height of the emergency middle section 4 is 40m, and the height of the connecting production middle section 4 is 60m~80m.

[0022] Before the open-pit mining stage 1 is closed, the construction of the underground mining system starts to connect the production...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com