Gently inclined medium-thick-thick large ore body remaining ore stopping method

A technology of gently inclined medium-thick, thick and large ore bodies, which is applied in ground mining, mining equipment, earthwork drilling, etc., can solve the problems of difficult mining and poor safety of mining operations, and achieve the effect of guaranteeing ore recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

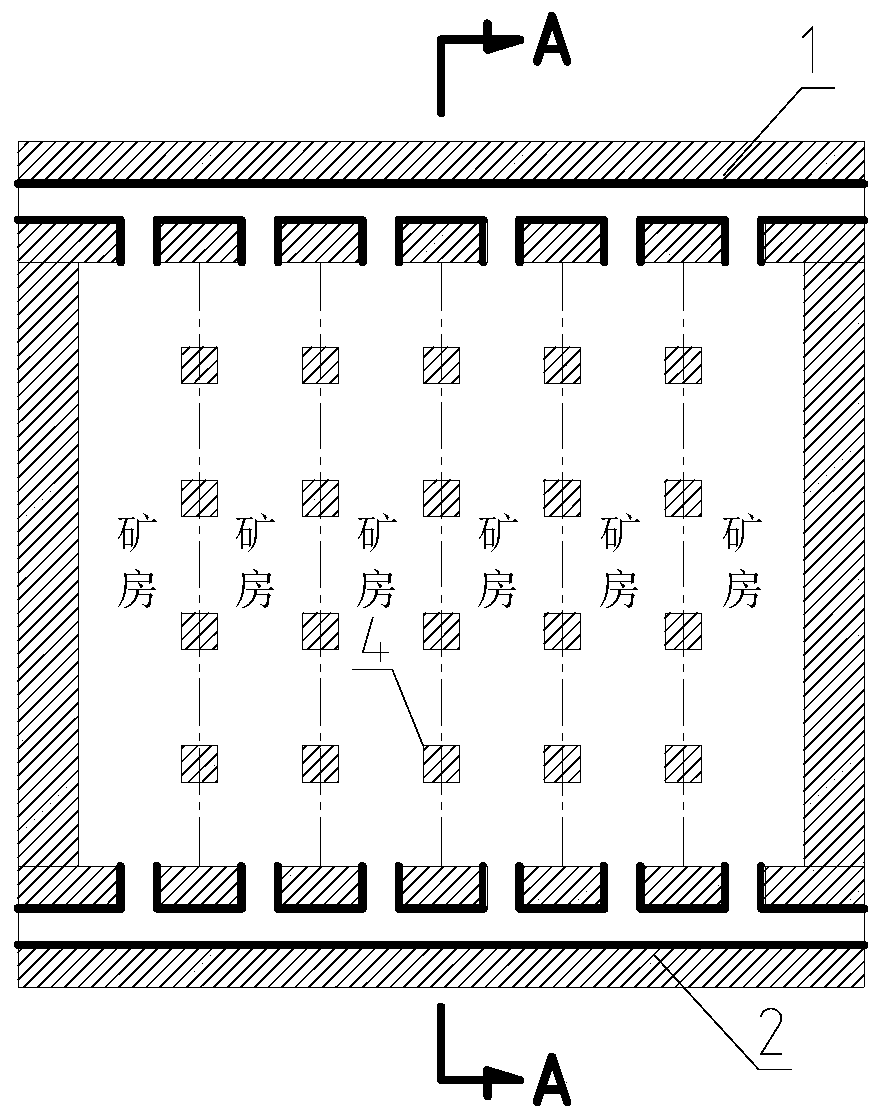

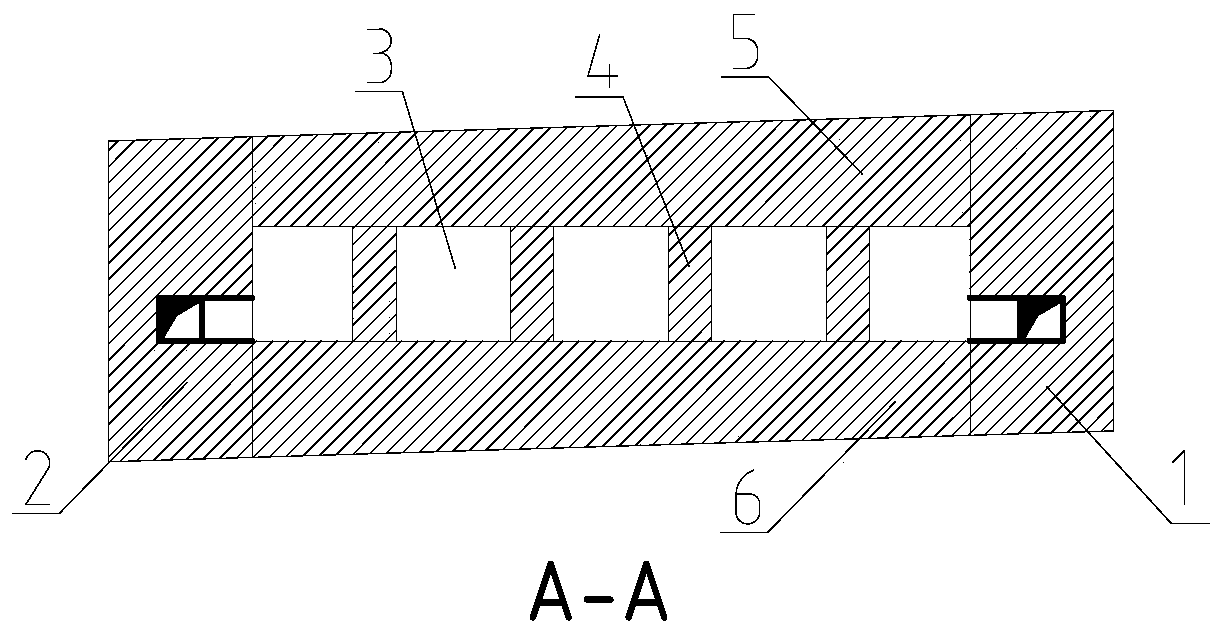

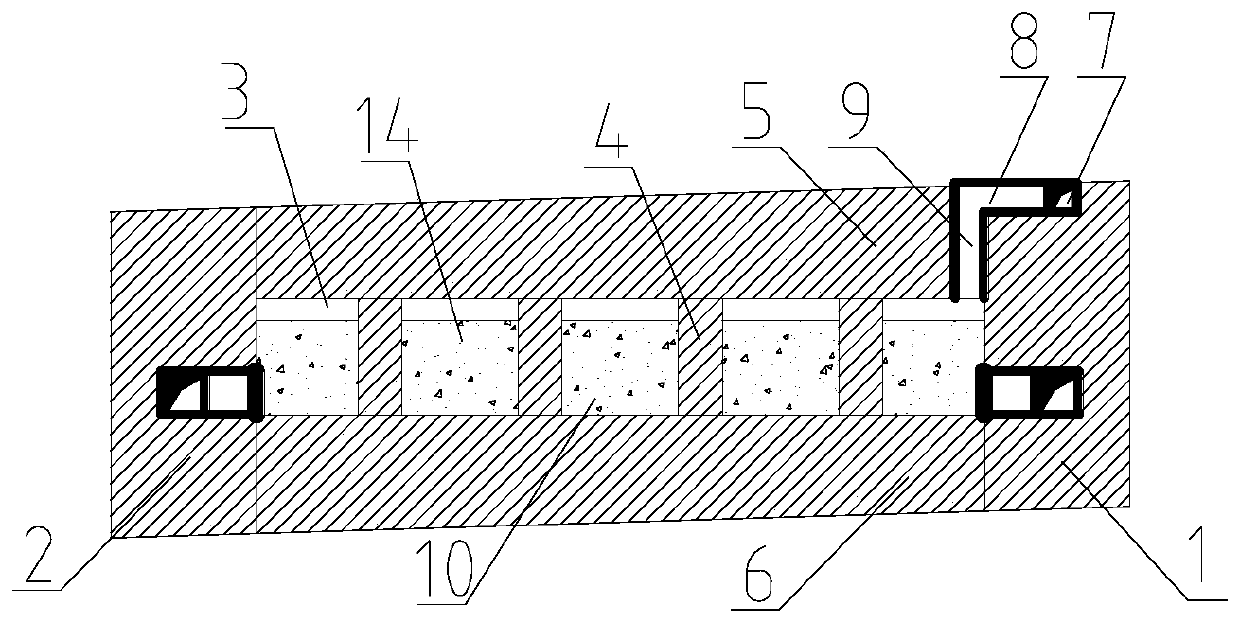

[0032] A method for recovering residual ore of a gently inclined medium-thick-thick ore body provided by the invention comprises the following steps:

[0033] (Step 1), filling the return airway 7 from the upper wall of the top column 1 in the upper middle section, the size of the section of the filling return airway 7 is 3m × 3m, and adopting the filling connection roadway 8, filling the return air shaft 9 and the recovery of the original room and pillar method The old empty area 3 is connected, the connecting roadway 8 and the return air shaft 9 are filled with a section size of 2m×2m, and the old empty area 3 is filled with high-strength cemented filling body 10. The 60-day uniaxial resistance of the high-strength cemented filling body 10 is The pressure should be greater than or equal to 3MPa, and it is not required to be connected to the top when filling, and the old empty space 3 at the top 1.5 is reserved as the free surface and compensation space for the mining and blas...

Embodiment 2

[0039] A method for recovering residual ore of a gently inclined medium-thick-thick ore body provided by the invention comprises the following steps:

[0040] (Step 1), filling the return airway 7 from the upper wall of the top column 11 in the upper middle section, the section size of the filling return airway 7 is 3m × 3m, and adopting the filling connection roadway 8, filling the return air shaft 9 and the recovery of the original room and pillar method The old empty area 3 is connected, the connecting roadway 8 and the return air shaft 9 are filled with a section size of 2m×2m, and the old empty area 3 is filled with high-strength cemented filling body 10. The 60-day uniaxial resistance of the high-strength cemented filling body 10 is The pressure should be greater than or equal to 3MPa, and it is not required to be connected to the top when filling, and the old empty space 3 at the top 1.5 is reserved as the free surface and compensation space for the mining and blasting o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com