Medium-length hole mining method in multiple blasting free faces of high dipping thin veins

A thin ore vein and steeply inclined technology, which is applied in the mining of inclined to steeply inclined thin ore bodies, and in the field of medium and deep hole mining methods with multiple blasting free faces of steeply inclined and thin ore veins, to achieve the effect of high operating safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

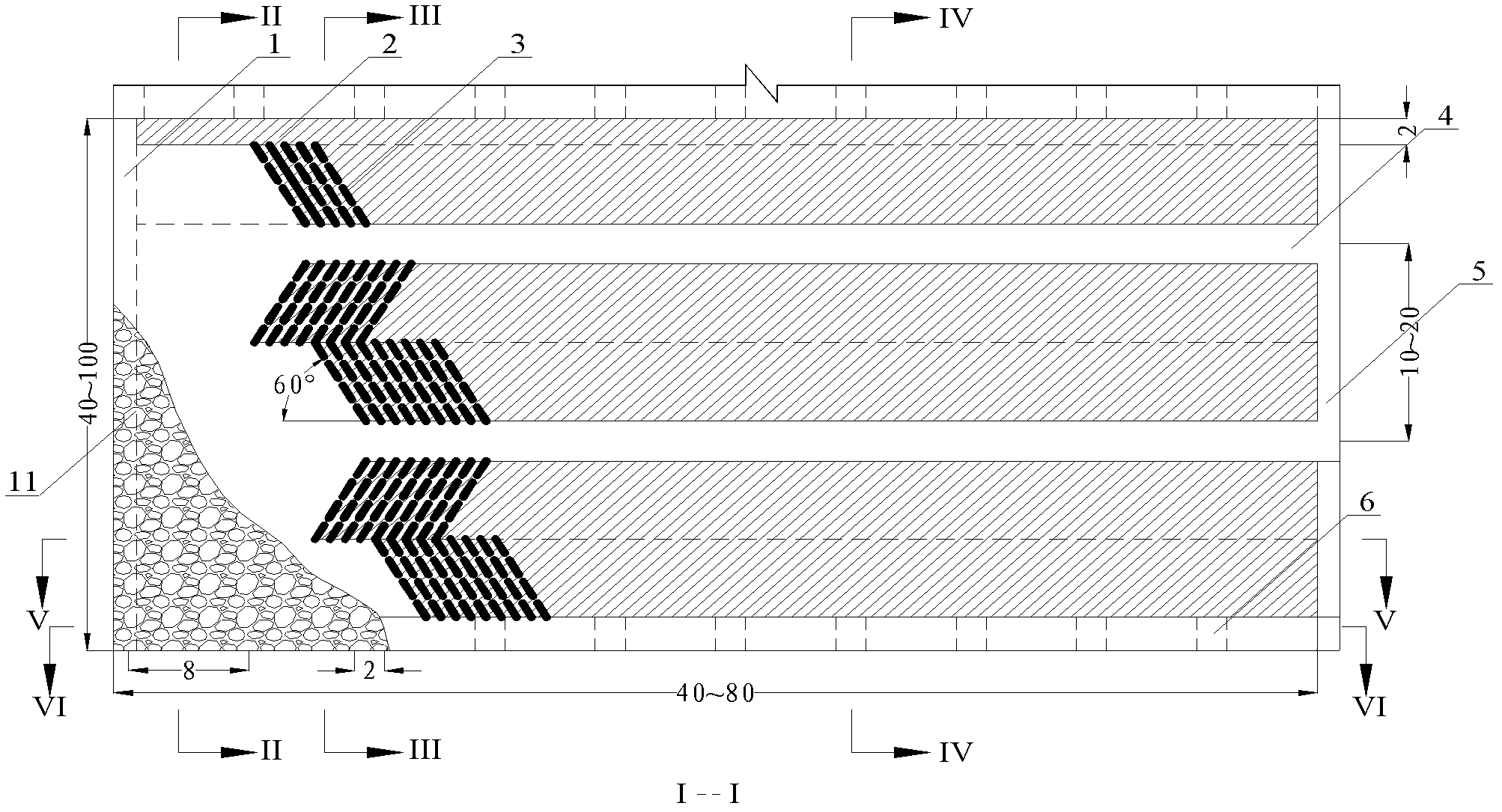

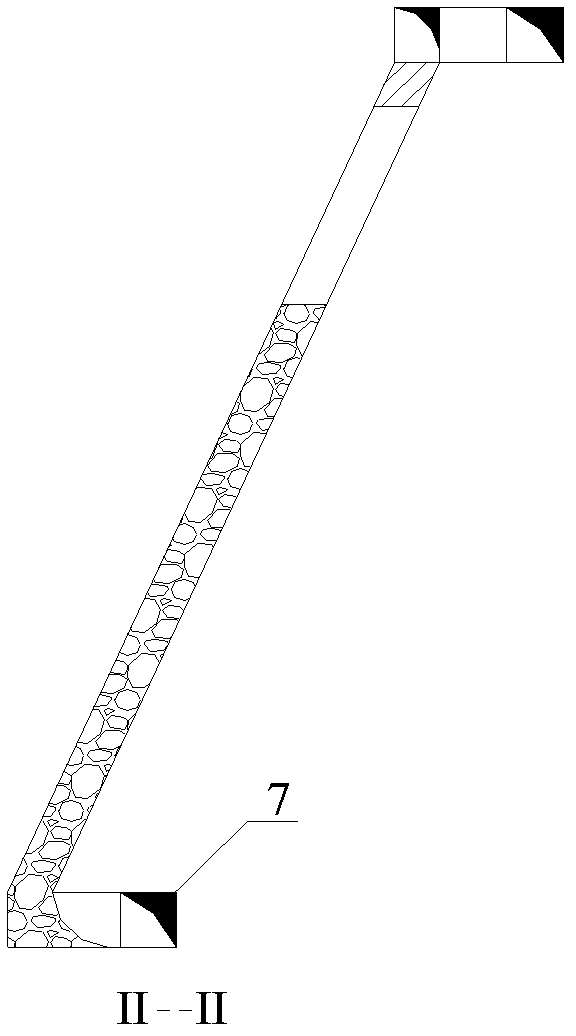

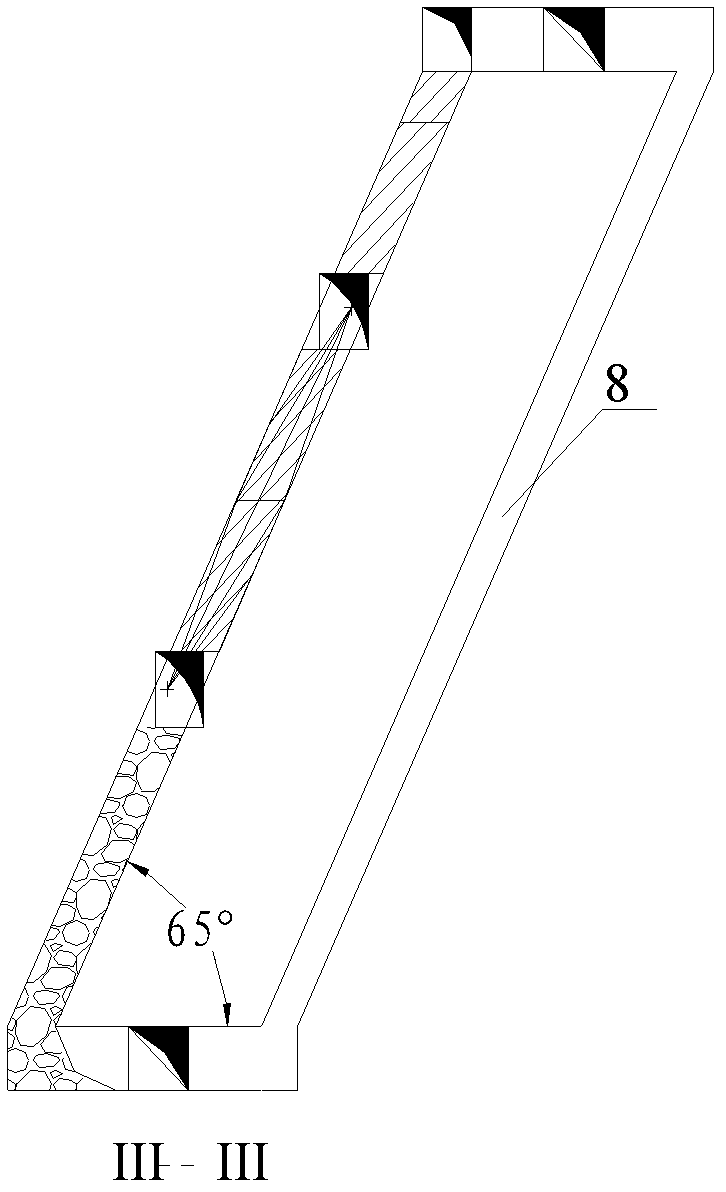

[0032] see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Figure 6 , the steps of the deep hole mining method in the steeply inclined thin vein multi-blasting free surface are as follows:

[0033] ①Arrange the ore blocks along the direction of the ore body 10, divide the ore body 10 into middle sections and sections in terms of vertical height, the ore blocks are 80m long and 50m high, and the ore blocks are divided into multiple sections with a section height of 18m. The design adopts a flat-bottomed structure, and the tunnel 7 is excavated from the middle section of the lower plate vein at the bottom of the ore block to the ore body 10, and the bottom rock-drilling tunnel 9 is dug inside the ore body 10, and a tunnel is arranged every 8m as the bottom of the mine house Out of mine side alley 6. The cutting patio 1 is arranged on one side of the mine house; the pedestrian equipment shaft 5 is arranged on the other side. The sectioned rock drilling level r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com