Method of combining gas replacement with vibration field for extracting natural gas hydrate reservoir

A gas replacement and natural gas technology, which is applied in the development of fluids, earthwork drilling, wellbore/well components, etc., can solve the problems of low production rate and efficiency, improve efficiency and rate, maintain reservoir stability, and increase rate and efficiency effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A method for exploiting natural gas hydrate reservoirs by combining gas replacement and vibration field, specifically comprising the following steps:

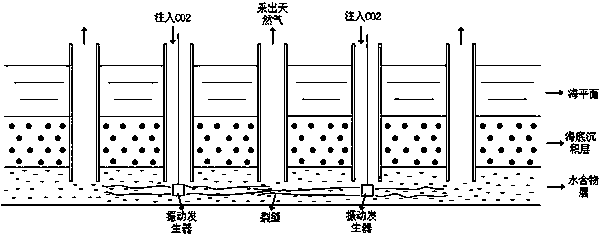

[0029] like figure 1 , arranging CO in gas hydrate reservoirs 2 Medium injection wells and natural gas production wells. If there is free gas in the reservoir, the pressure of the hydrate reservoir is reduced to 3-5MPa by first producing part of the free gas through the production well. then from CO 2 The medium injection well puts a vibration generator into the reservoir.

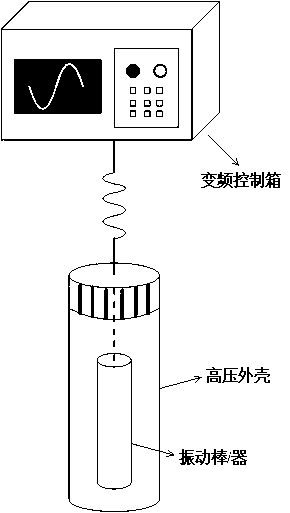

[0030] like figure 2 , the vibration generator is located in a high-pressure, sealed steel kettle, the vibration generator is connected to an external frequency conversion control box through a lead wire, and the high-pressure shell of the high-pressure steel kettle is used to prevent the vibration generator from being damaged by direct contact with seawater.

[0031] CO was subsequently injected at an injection pressure of 4-8 MPa 2 medium. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com