Strip mine continuous mining system

It is an open-pit mine and continuous technology, which is applied in open-pit mine mining, earth drilling, special mining, etc. It can solve the problems of huge maintenance workload, high procurement cost, and low mining efficiency, and achieve low procurement and management costs. The effect of simple structure and wide adaptability to conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

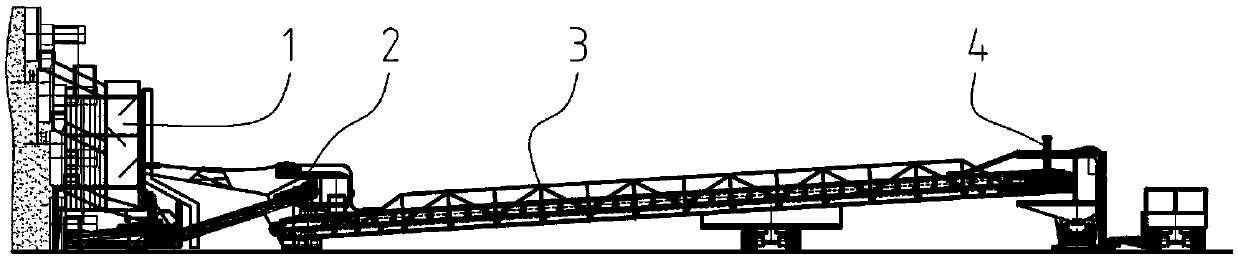

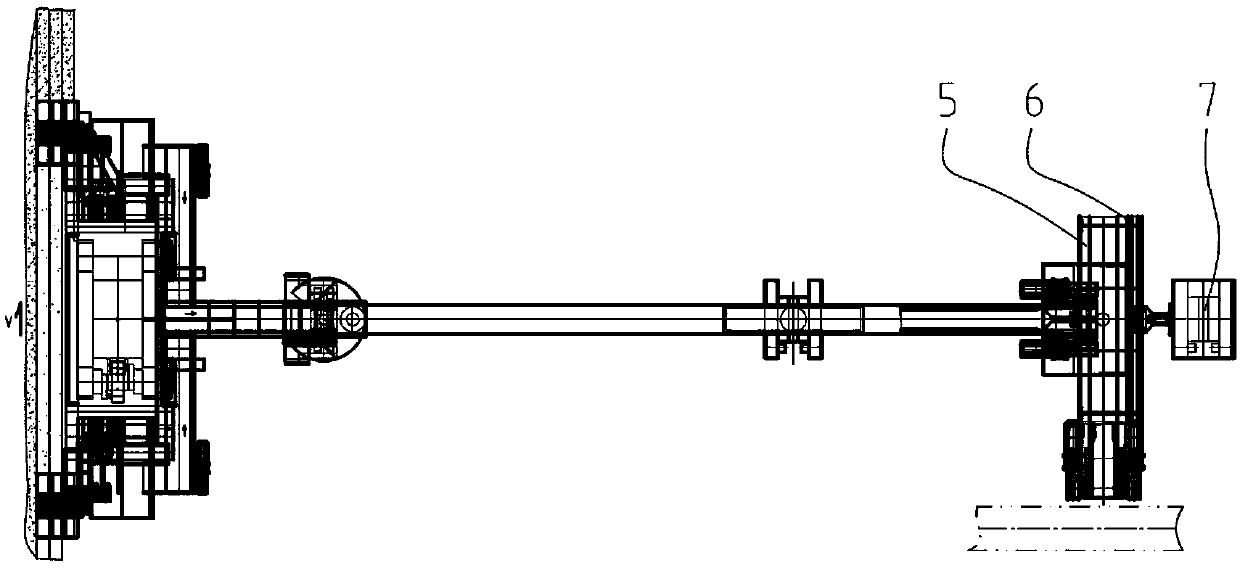

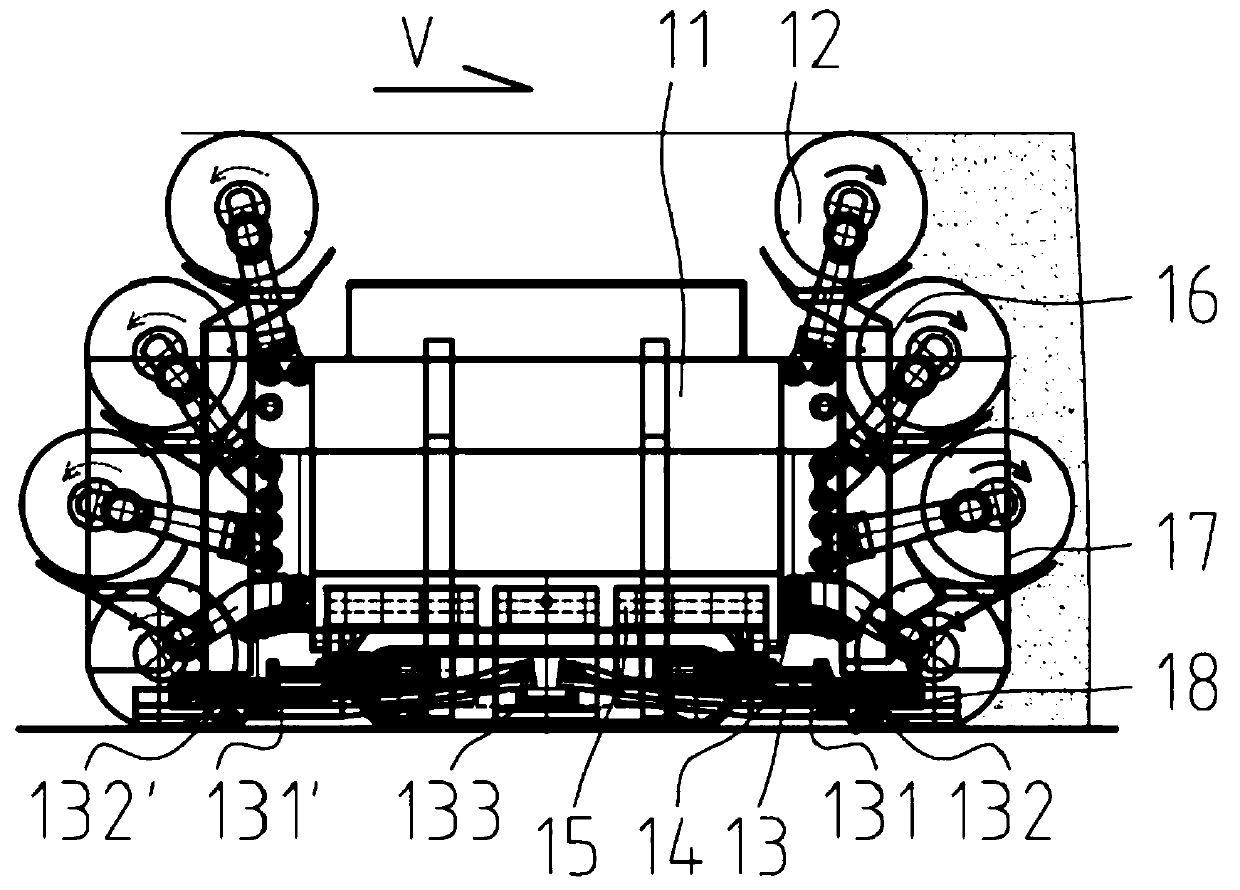

[0046] Such as Figures 1a-8b As shown, the present invention discloses a continuous mining system for an open-pit mine, which includes a mining machine 1 , a transfer conveyor 3 and a working face conveyor 5 . The rear end of the intermediate conveying device 133 of the mining machine is hinged with the front end of the reloading conveyor through the front-stage connection mechanism 2, the hinge axis extends vertically, and the rear end of the intermediate conveying device of the mining machine is located at the reloading conveyor. above the front end of the conveyor. At least one place below the main body of the transfer conveyor is provided with universal wheels. The rear end of the transfer conveyor is hinged to a rear-stage connecting mechanism 4, and the hinge axis extends vertically. The rear connecting mechanism is provided with a rear receiving hopper, the latter is located below the rear end of the transfer conveyor, and the discharge port of the latter is located ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com