A kind of natural caving mining method of inverted cone-shaped ore accumulation

A mining method and caving mining technology, applied in earth-moving drilling, slitting machinery, discharging machinery, etc., can solve the problems of difficult roadway support, high cost, low mining efficiency, etc., to reduce production and operation costs, The effect of reducing intermediate links and reducing the amount of engineering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

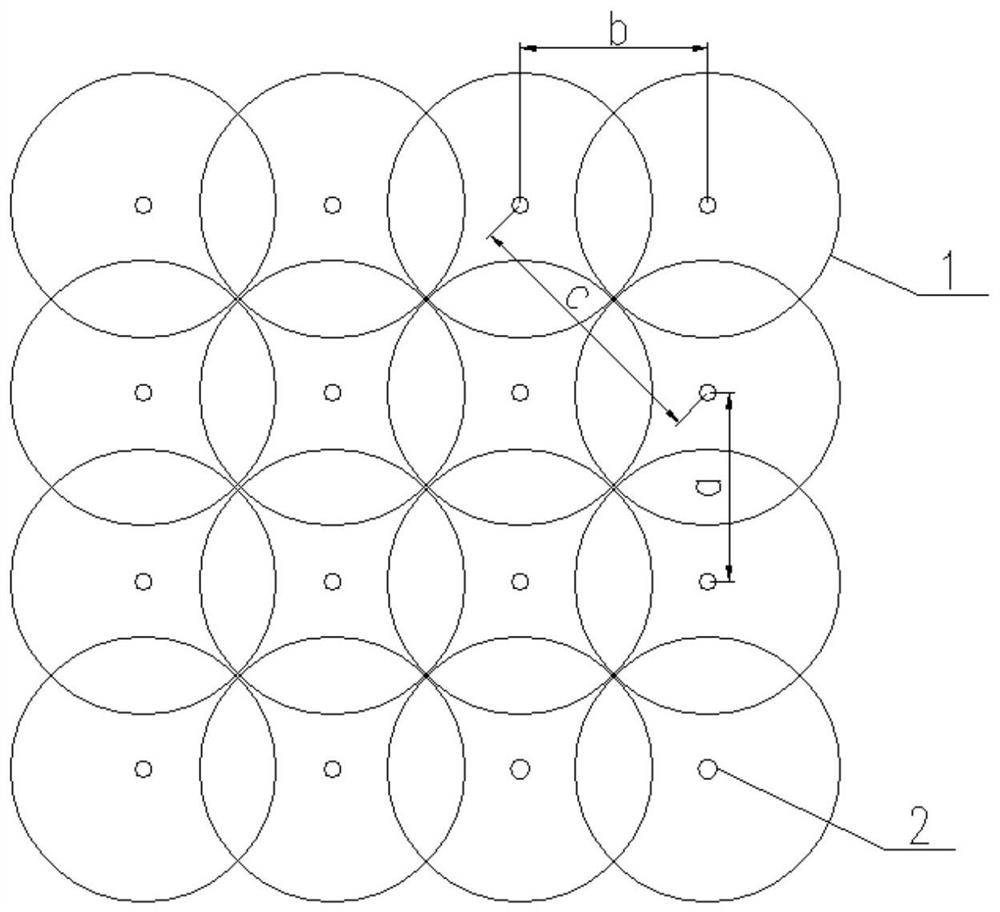

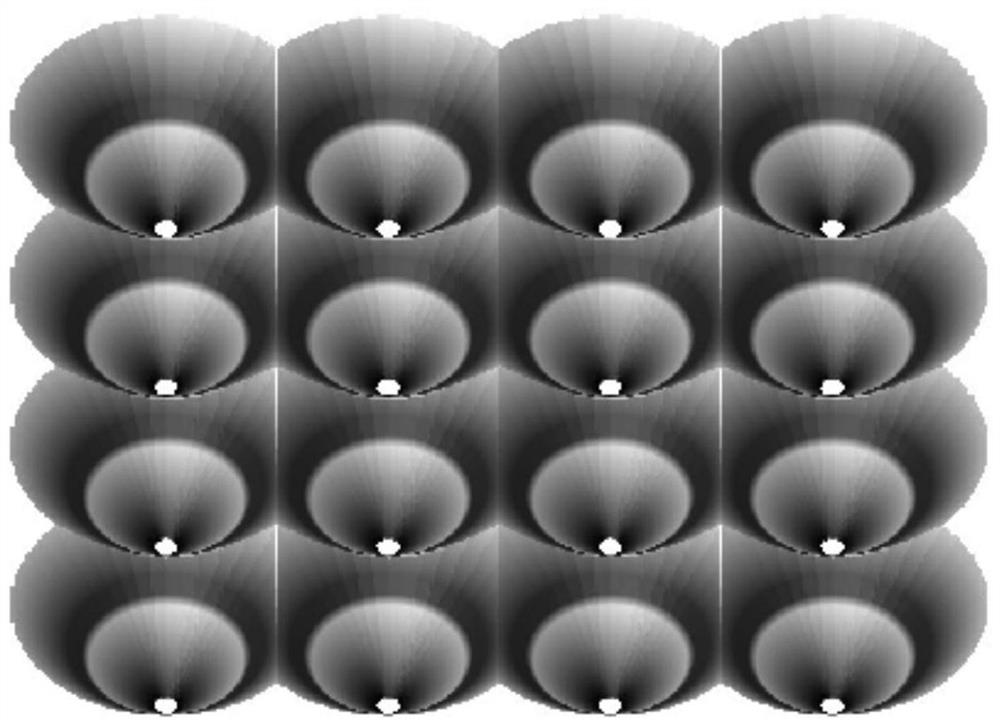

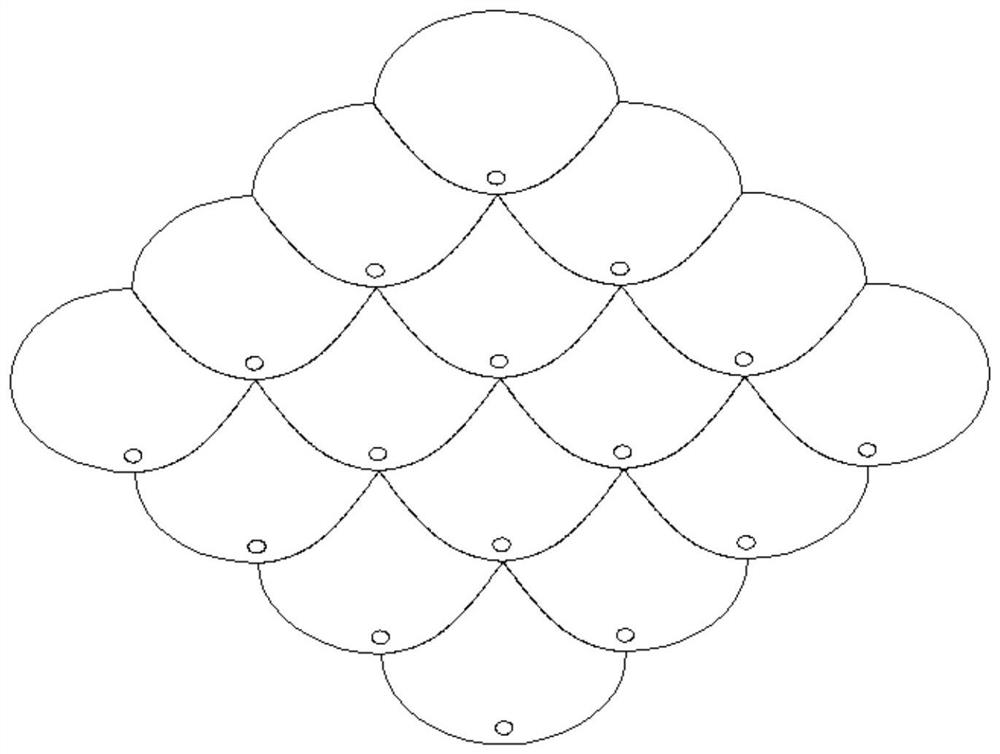

[0016] like Figure 1-5 As shown in the figure, a natural caving mining method of rounded table-shaped ore accumulation is characterized in that the rounded table-shaped ore-gathering groove is arranged in a determinant manner, the row spacing (a) of the rounded table is equal to the column distance (b) of the rounded table, and the top surface of the rounded table (1) As the entrance of the caving ore, the diameter of the top surface (1) of the rounding table is 1.414 times the row spacing (a) or the column spacing (b) of the rounding table. The upper top surface (1) circle intersects and is tangent to the upper top surface circle of the adjacent circular platform on the diagonal line, the shape of the middle rounded platform ore-gathering tank is square, and the shape of the top surface (1) of the rounded platform of the rounded platform ore-gathering tank on the edge is Combination of circle and square; the lower top surface (2) of the rounding table is connected to the chu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com