The Method of Using Aeolian Sand to Fill the Net Cage to Construct the Wall of Gob-side Entry Retention

A technology of aeolian sand and net cages, which is applied to filling materials, earth square drilling, mining equipment, etc., which can solve problems such as surface water shortage, unsuitability, and thin bedrock, so as to reduce construction costs, ensure support effects, and improve The effect of recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

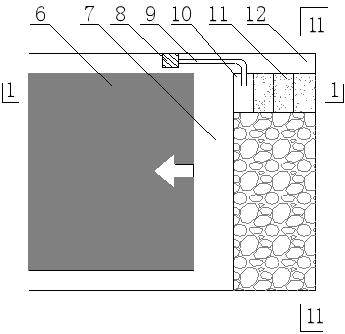

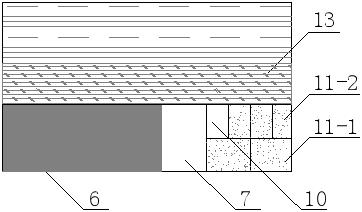

[0027] In the figure, the operation steps of the method of using aeolian sand to fill the net cage to construct the wall of the gob-side entry roadway protection are as follows:

[0028] ① After the working face 7 is pushed through, level the bottom plate at the reserved road wall;

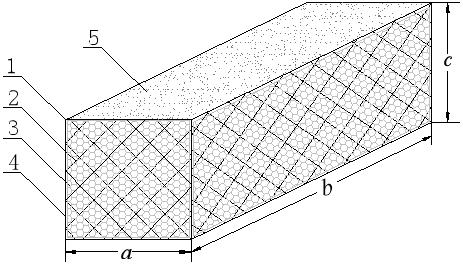

[0029] ②Prefabricated steel wire cage 1 on the ground, the length a of the cage is 1 / 2 of the length of one construction of the roadway wall (generally the advancing length of the working face 7 in one day); the width b of the cage is 1 / 2 of the length a of the cage; The height c of the net cage is 1 / 4-1 / 2 of the height of the working surface 7, and 0.5 m≤c≤1.0 m;

[0030] ③Arrange the prefabricated steel wire cages 1 in the floor area of the reserved alley wall after leveling, and use iron wires to overlap the edges 4 of the adjacent steel wire cages to ensure that the tensile strength of the lap joints is not lower than that of the steel wire mesh 2 80% of the tensile strength;

[0031] ④ la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com