Method used for reciprocating impact excavation by arranging discharge port for discharging, and reciprocating impact excavator used for implementing method by arranging discharge pot for discharging

An excavator and material hole technology, which is applied in the field of machinery, can solve the problems of inability to discharge and the inability of continuous production of multi-layer impact head excavators.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

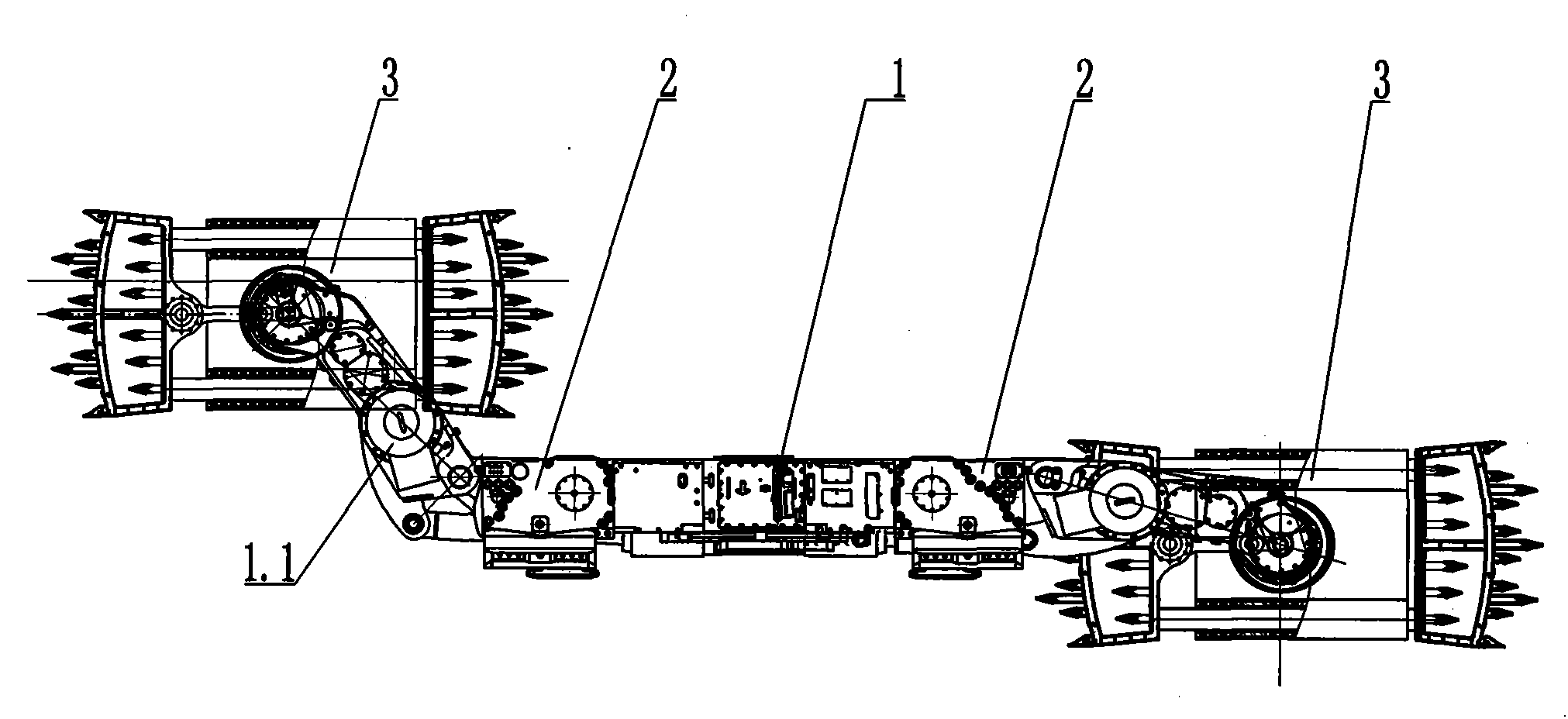

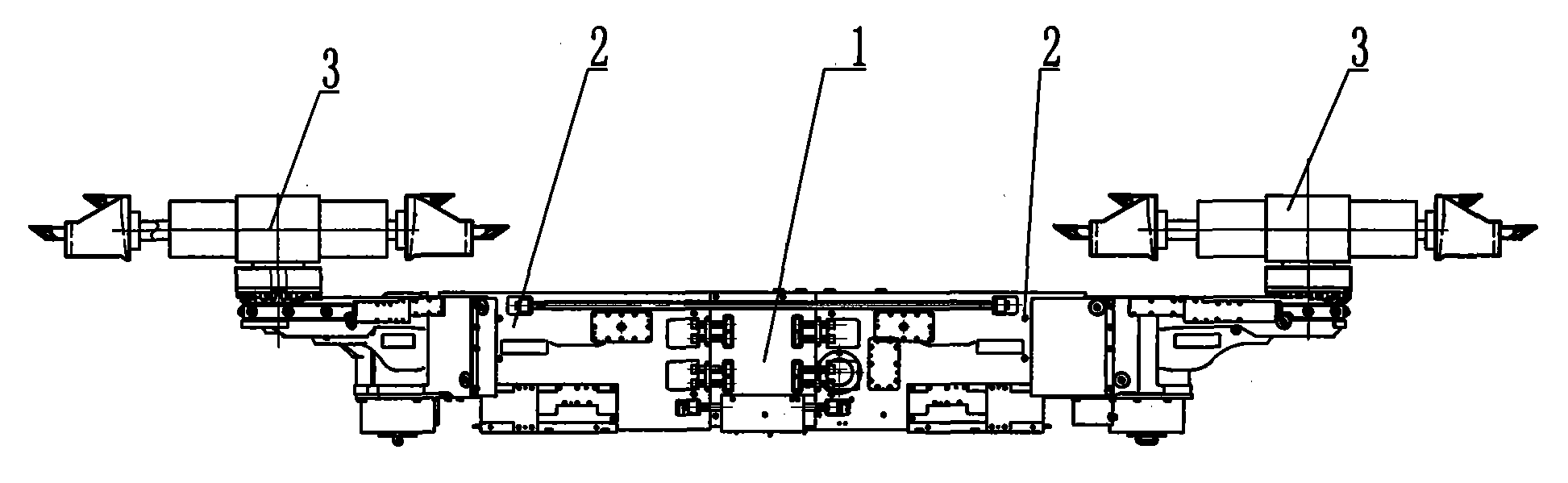

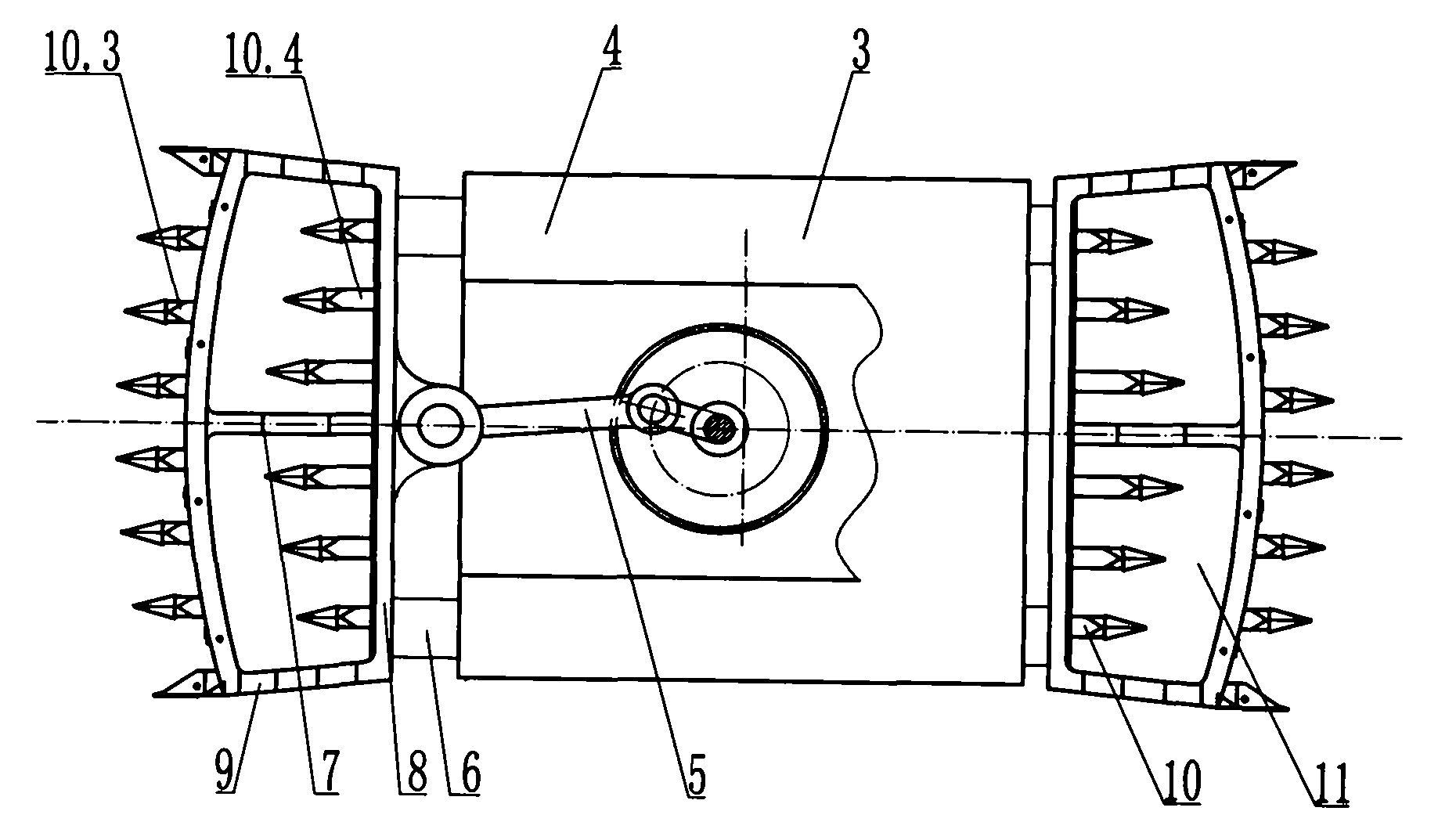

[0098] Such as Figure 1 to Figure 8 As shown, a reciprocating impact mining machine is provided with a discharge hole, including a body 1, a traveling mechanism 2, etc., and an impact blanking mechanism 3, etc. The impact blanking mechanism 3 includes an impact power box 4 and a power impact piece 5 , impact guide 6, impact head 7, etc., the impact head 7 is composed of a support seat 8, punching teeth 10, etc., the support seat 8 includes a discharge hole frame 9, etc., and the discharge hole frame 9 includes one or more discharge holes 11. The support seat 8 is equally connected with the discharge hole frame 9 or integrated. The punching teeth 10 are set on the discharge hole frame 9 or the punching teeth are arranged on the discharge hole frame 9 and the support seat 8. The punching teeth 10 Including punching the outer layer material tooth 10.1, punching the inner layer material tooth 10.2, etc., the shape and / or arrangement of the punching outer layer material tooth 10.1...

Embodiment 2

[0118] Such as Figure 9 to Figure 10 As shown, the discharge hole 11 is a trapezoidal discharge hole, and may also be an arc-shaped discharge hole, a square discharge hole, an arched discharge hole, a triangular discharge hole, or a special-shaped discharge hole.

[0119] Both ends of the impact guide 6 are asymmetrically provided with supporting seats 8, and the impact guide 6 and the supporting seats 8 are equally connected or integrated.

[0120] An anti-damage impact driver structure 20 and the like are provided between the power impact member 5 and the support base 8 or on the power impact member 5 , and the power impact member 5 and the support base 8 are connected equally or separately or integrally.

[0121] The anti-damage impact driver structure 20 includes a rotating anti-damage impact driver structure 20.1, etc., the power impact member 5 drives the punching tooth 10 to impact, the impact reaction force is applied to the anti-damage impact driver structure 20, etc...

Embodiment 3

[0129] Such as Figure 11 to Figure 16 As shown, a reciprocating impact mining machine is provided with a discharge hole, including a body 1, a traveling mechanism 2, etc., and an impact blanking mechanism 3, etc. The impact blanking mechanism 3 includes an impact power box 4 and a power impact piece 5 , impact guide 6, impact head 7, etc., the impact head 7 is composed of a support seat 8, punching teeth 10, etc., the support seat 8 includes a discharge hole frame 9, etc., and the discharge hole frame 9 includes one or more discharge holes 11. The support seat 8 is equally connected with the discharge hole frame 9 or integrated. The punching teeth 10 are set on the discharge hole frame 9 or the punching teeth are arranged on the discharge hole frame 9 and the support seat 8. The punching teeth 10 Including punching the outer layer material tooth 10.1, punching the inner layer material tooth 10.2, etc., the shape and / or arrangement of the punching outer layer material tooth 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com