Electric-driven track travelling type open-air continuous coal cutter

A walking, electric-driven technology, applied in the direction of driving devices, cutting machinery, earthwork drilling, etc., can solve the problems of increased cost per ton of coal, low production efficiency, large coal lumps, etc., to reduce the cost of coal per ton, improve Production efficiency, satisfying the effect of rapid mobilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below with reference to the accompanying drawings and embodiments, and the mode of the present invention includes but not limited to the following embodiments.

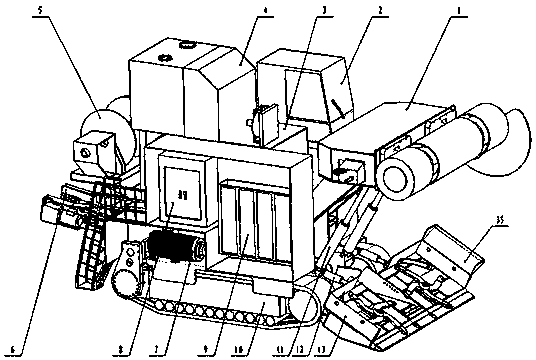

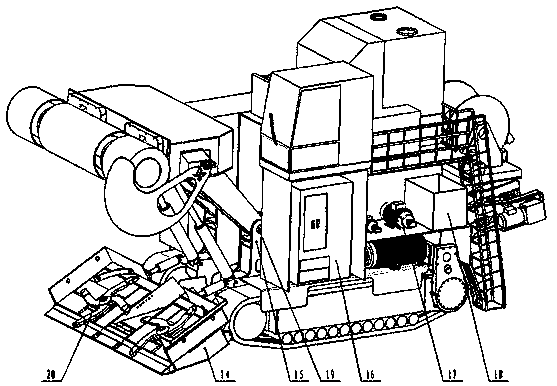

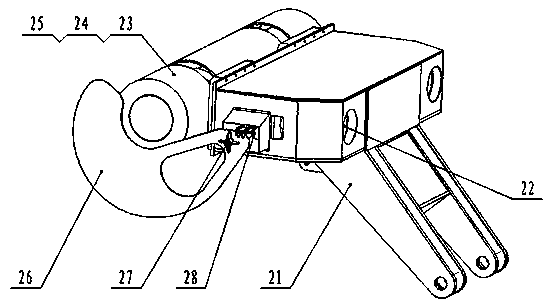

[0034] This embodiment provides an electrically driven crawler walking type surface continuous miner, see figure 1 with figure 2 , the shearer mainly includes a cutting part 1, a loading part 13, a conveying part 6, a traveling part 10, a main frame 15, a cab 2, and a cable winding device 5. Its walking adopts 690V AC frequency conversion speed regulation electric traction system, which can meet the requirements of fast mobilization, frequent start and stop, reversing and cutting feed force. And it has the advantages of wide speed range, large starting torque, strong overload capacity, etc. At the same time, the walking AC frequency conversion motor and cutting motor are designed as a closed-loop automatic control system, and the walking AC frequency conversion ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com