A Mining Method for Segmented Filling of Inclined Medium Thickness and Above Orebody

A backfill mining and ore body technology, applied in the fields of backfill, ground mining, mining equipment, etc., can solve the problems of reducing the requirements of backfilling and topping, reducing the amount of mining and cutting engineering, reducing the ore dilution rate, etc., to optimize the mining standard project. The effect of layout, reducing the amount of mining and cutting, and reducing the dilution rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

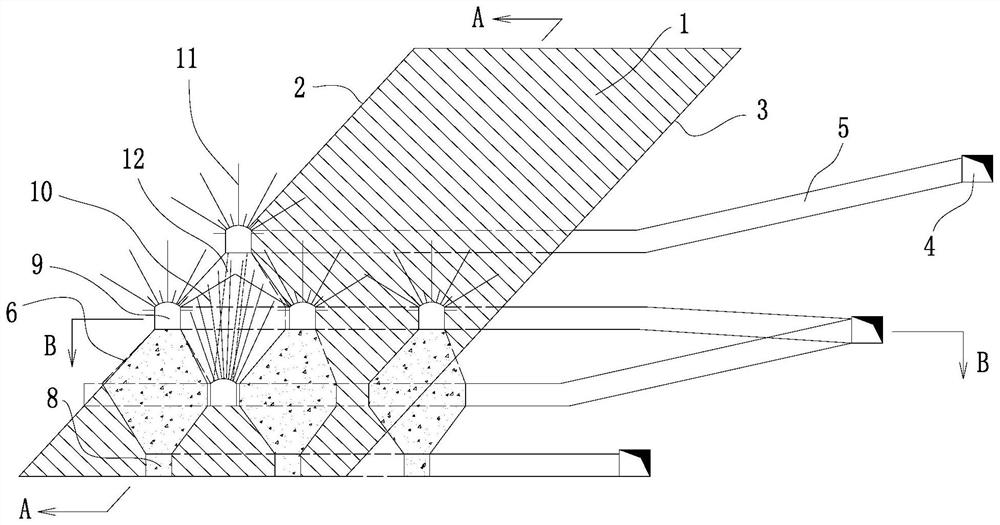

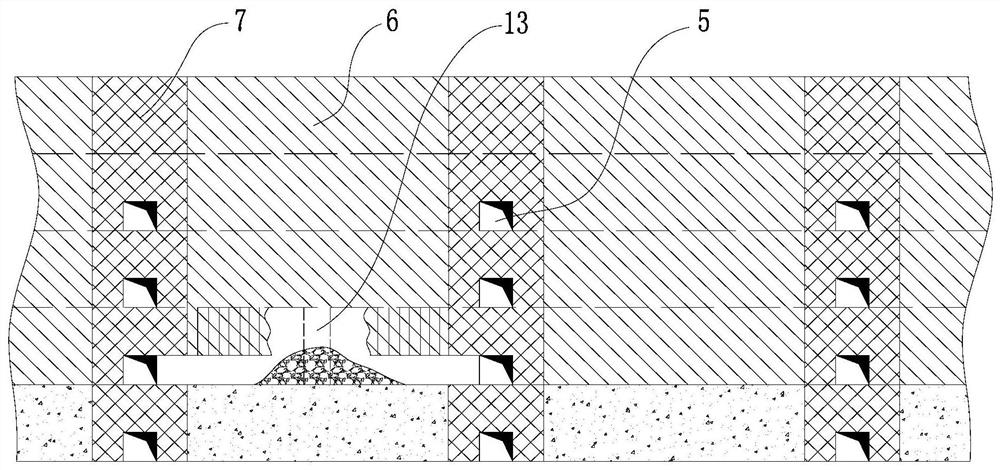

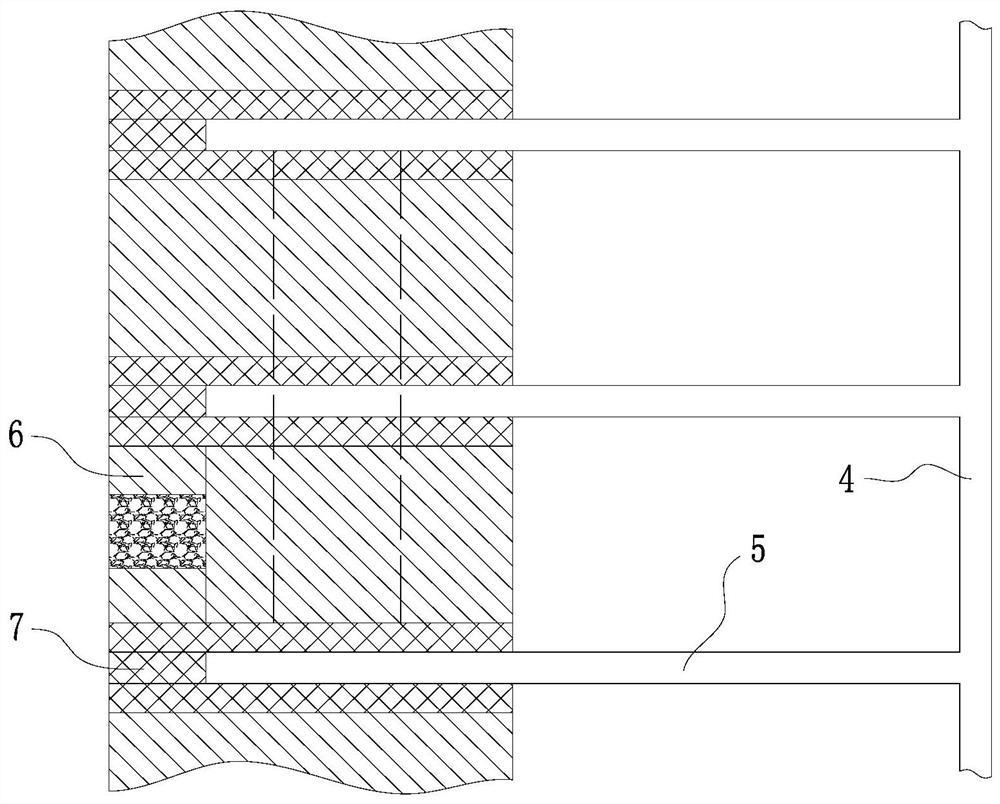

[0033] A mining method for segmental filling of inclined medium-thick ore bodies, the operating principle diagram is as follows Figure 1~3 shown, including the following steps:

[0034] Step 1: Stope structure and ore block layout

[0035] The stages are divided into segments, the ore block 1 is divided along the ore body strike direction or perpendicular to the ore body strike direction, and the ore house and the ore pillar 7 are further divided in the ore block 1, and the mine house is rhombus in shape and used as a rhombus stope 6, and The height of rhombus stope 6 is the height of two subsections, the width and length of rhombus stope are determined according to the stability of ore body 1, and the adjacent rhombus stope 6 is distributed up and down; When the body strike direction is parallel and the dip angle is steep, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com