Drum-type continuous excavator

A drum type and excavator technology, which is applied to mechanically driven excavators/dredgers, earth movers/shovelers, conveyors, etc., and can solve problems such as long working strokes, long time-consuming single-way operation, and low excavation efficiency. problem, to achieve the effect of continuous mining

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

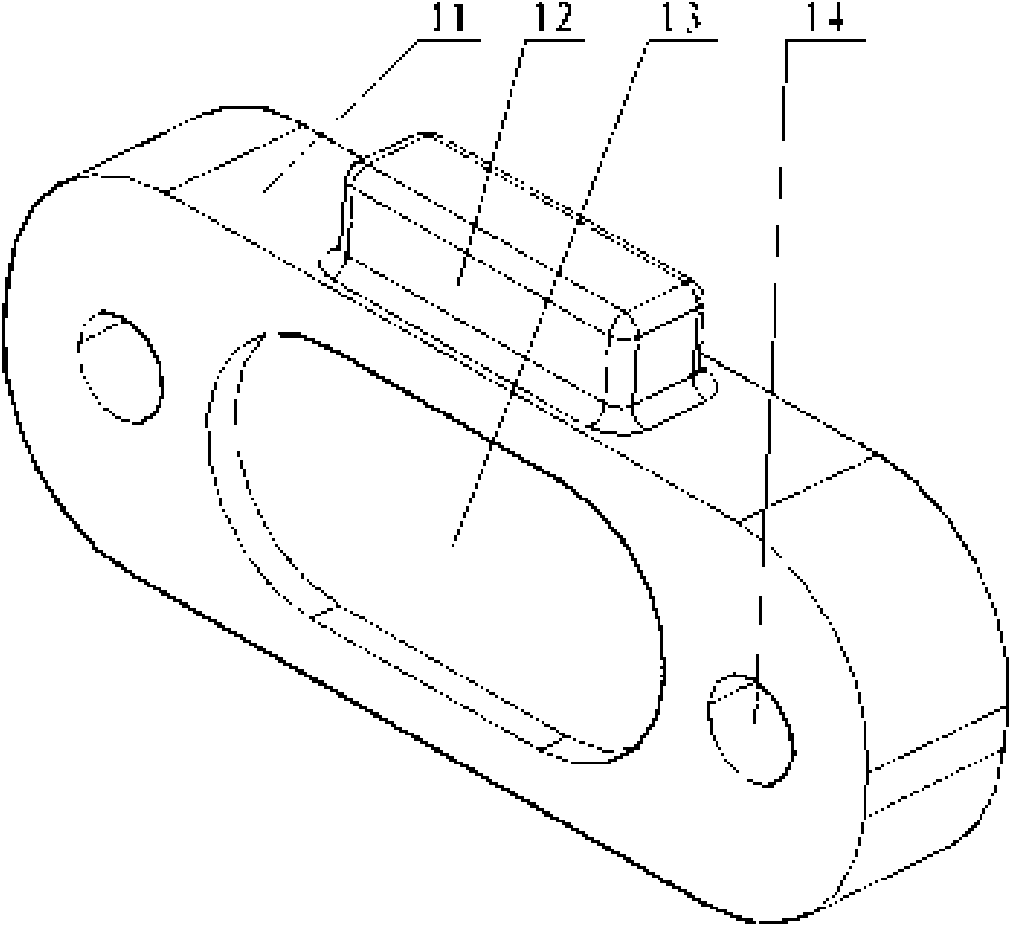

[0020] refer to Figure 4 , the present embodiment comprises power system 23, control system 24, excavation system, and described excavation system comprises roller bucket 15, and roller bucket 15 obliquely below and by being installed in the drive chain disk 20 of frame top, the guide of bottom The chain plate I16, the guide chain plate II17, the chain 18 and the chain type closed-loop loading system composed of several loading buckets 19 are connected at the low end; the high end of the chain type closed-loop loading system is provided with a receiving hopper 21, and the outlet of the receiving hopper 21 is connected to the chute 22 High-end connections.

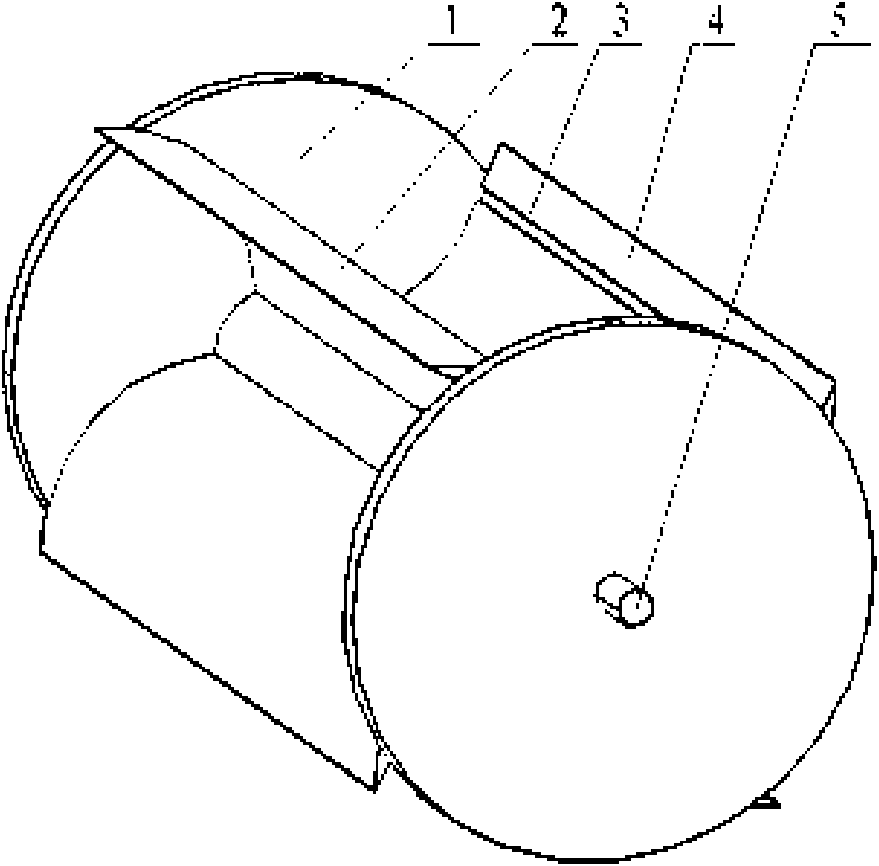

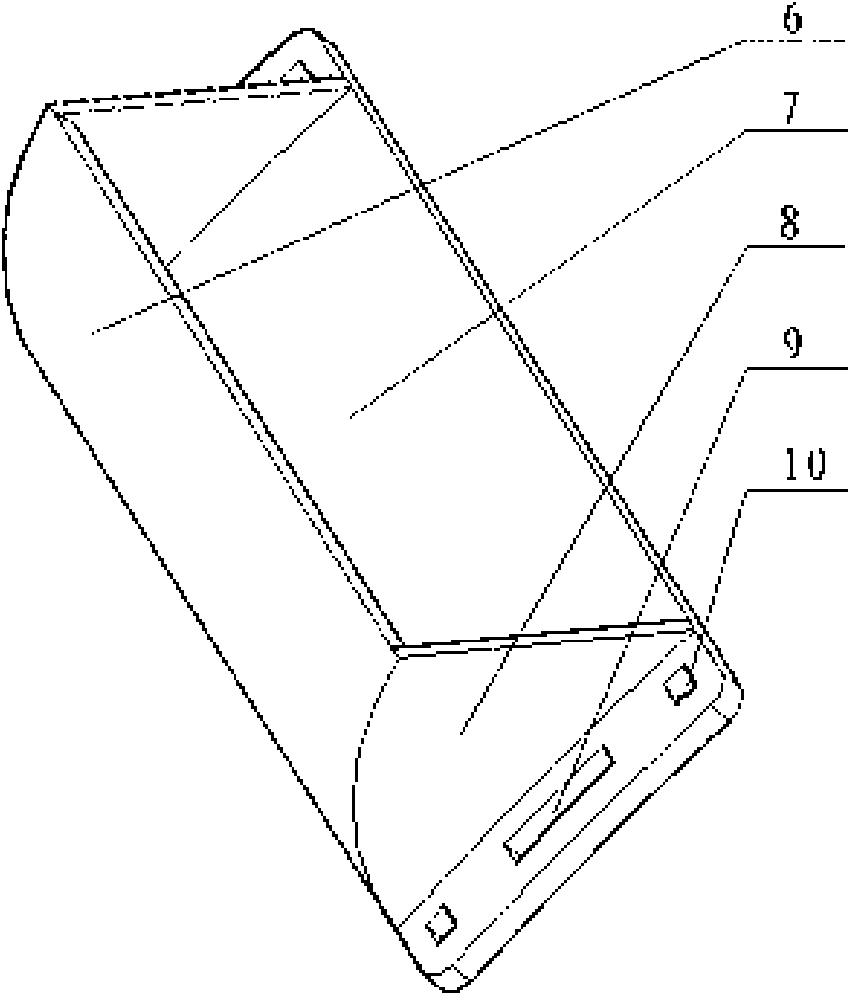

[0021] refer to figure 1 , the drum-type bucket includes a shovel plate 15, a blade seat 3, a blade 4, and a fixed shaft 5. The cross-section of the blade 15 is arc-shaped, and is fixed o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com