An oil well desanding device based on pulse jet technology and cyclone separation mechanism

A technology of pulse jet and cyclone separation, which is applied in the fields of production fluids, wellbore/well components, earth-moving drilling, etc., can solve the problems of increasing oil and gas field production, unfavorable continuous production of oil wells, etc., and achieves the effect of convenient storage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Below in conjunction with accompanying drawing and the present invention is further described:

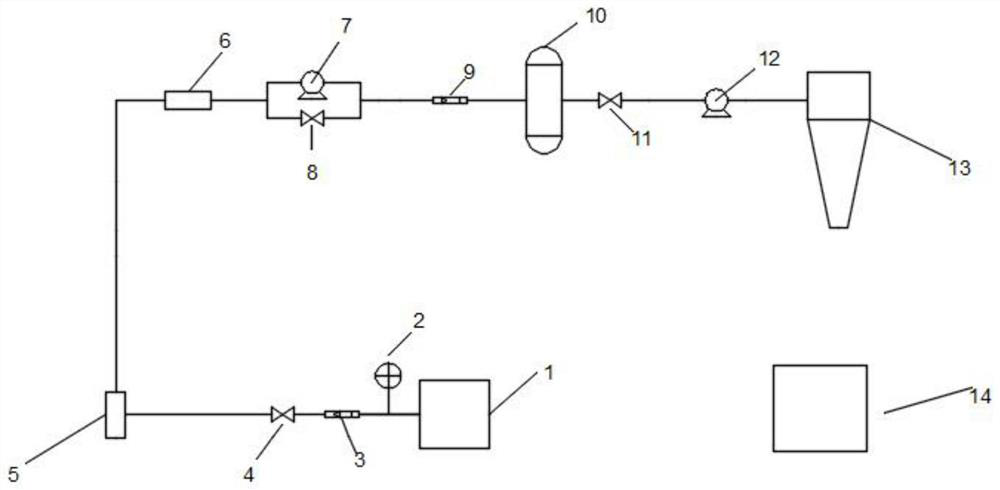

[0044] This embodiment relates to an oil well sand removal device based on pulse jet technology and cyclone separation mechanism. Its main structure includes a pulse jet sand pumping system, a ground buffer system, a three-phase cyclone degassing and sand removal system, and connecting pipelines. , control system and power system,

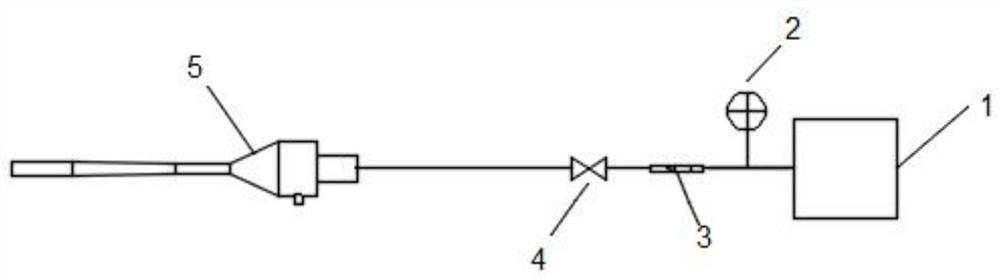

[0045] combine figure 2 with Figure 10, to describe this embodiment in detail, the pulse jet sand pumping system is the only equipment in the present invention that needs to go deep into the well, and its main structure includes an air compressor 1, a first pressure gauge 2, a first flow meter 3, and a first switch valve 4. The jet pump 5, wherein the air compressor 1, the first pressure gauge 2, the first flow meter 3, the first switch valve 4, and the jet pump 5 are connected in sequence through pipelines, and the first pressure gauge 2 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com