Air gap, air gap forming method and semiconductor device

A technology of air gap and conductive plug, which is applied in the direction of semiconductor devices, semiconductor/solid-state device manufacturing, semiconductor/solid-state device components, etc. The effect of large forming area, enhanced mechanical strength, and not easy to collapse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

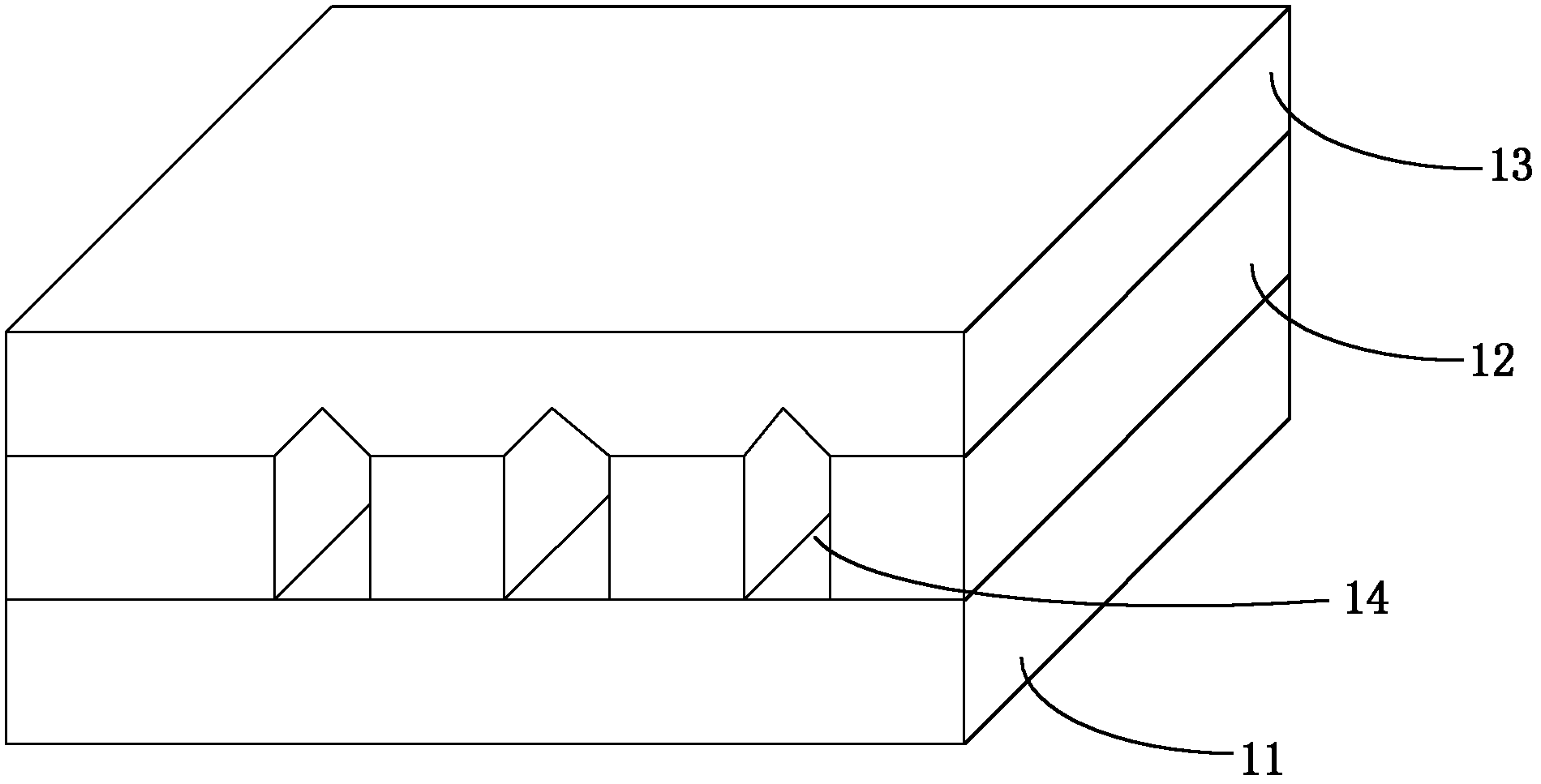

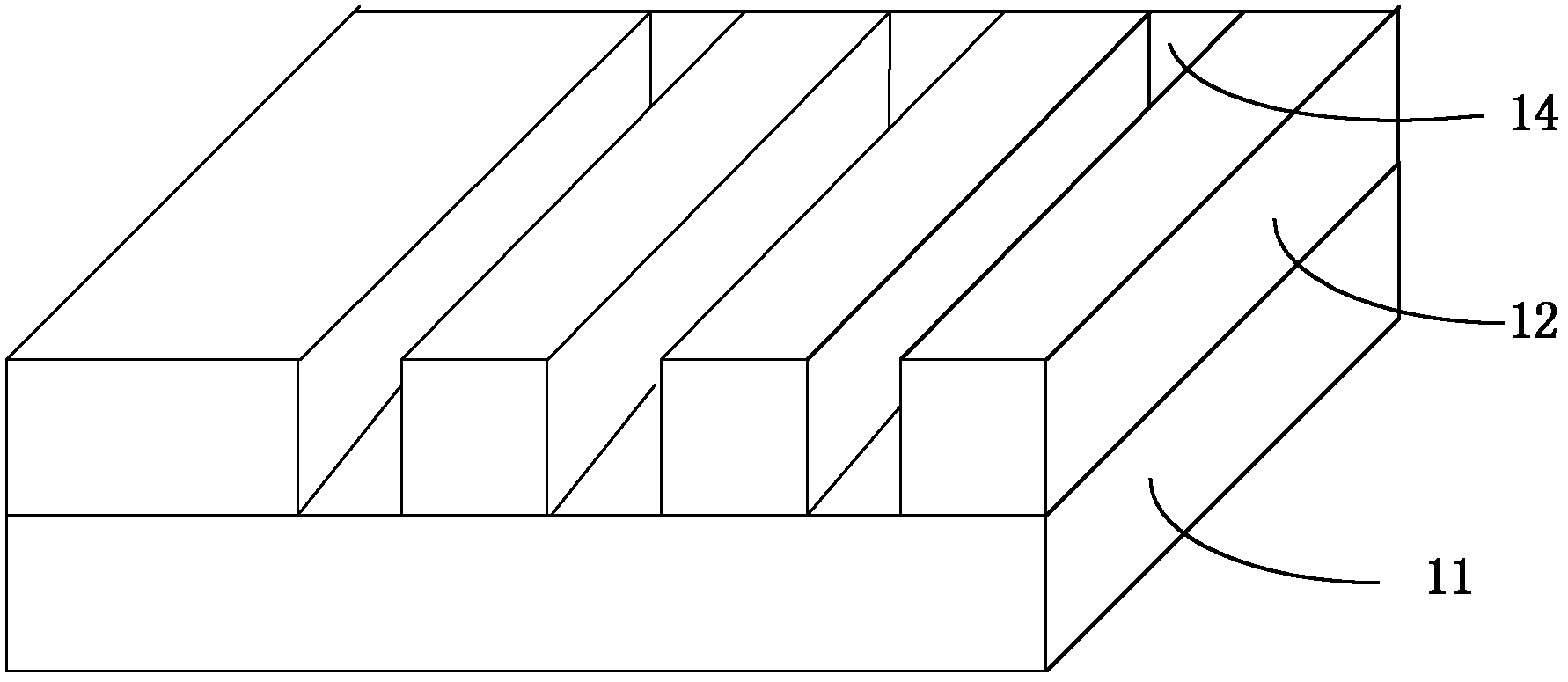

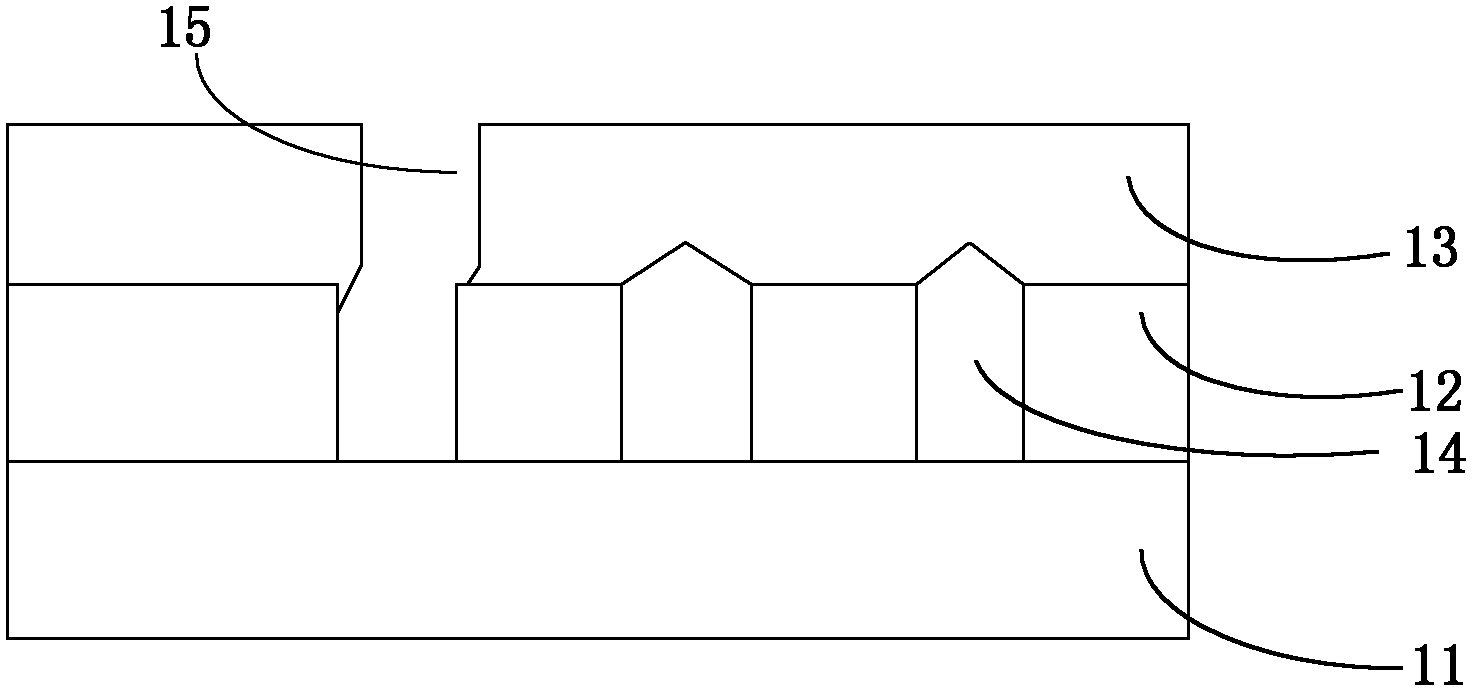

[0041] As mentioned in the background, the air gap in the prior art is in the shape of a long strip groove. When the top dielectric layer is deposited on it, the layer is easy to collapse. The self-alignment accuracy of the holes is required to be high, and the present invention proposes to use photolithography and etching to form air gaps in the intermetallic dielectric layer of the metal interconnection structure; wherein, the air gaps are honeycomb-shaped distributed A fat belly-shaped structure with small top and bottom areas and a large middle area. Compared with the elongated slot-shaped air gaps in the prior art, the honeycomb distribution has a greater impact on the top dielectric layer when depositing the top dielectric layer. The supporting force of the electrical layer is evenly distributed, so that the mechanical strength of the layer is enhanced and it is not easy to collapse. In addition, the area of the top and bottom is smaller than that of the elongated groov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com