Block-shaped cutting, jacking and pushing ore removal mining method of double-layer extreme-thin jade mine

A mining method and jade mining technology, applied in surface mining, mining equipment, underground mining, etc., can solve the problems of ore process value reduction, roof concentrated stress collapse, stress wave ore damage, etc., to achieve control of surface subsidence and high recovery rate , the effect of good integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

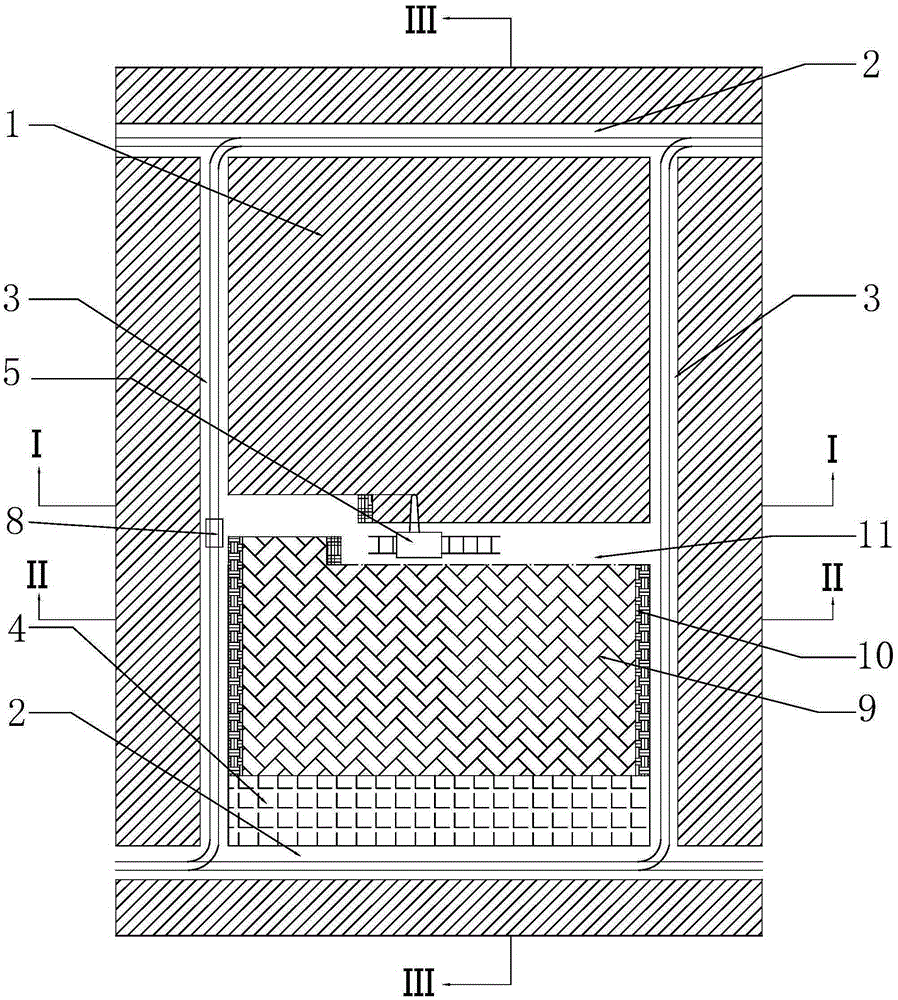

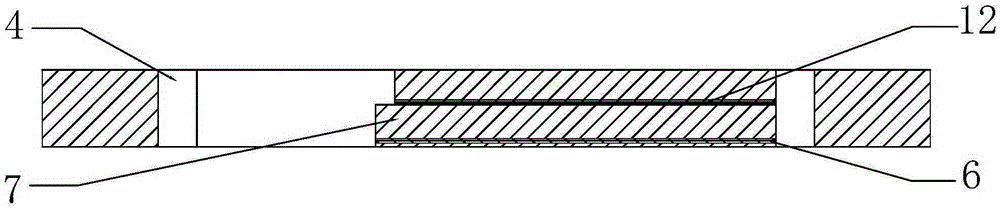

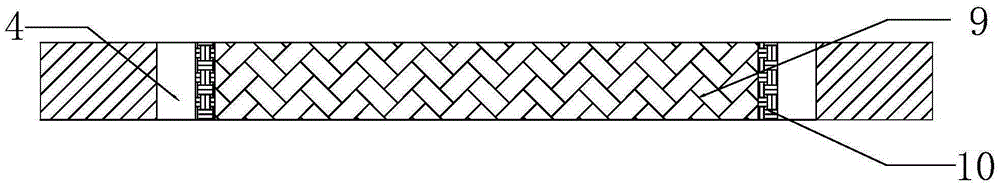

[0029] The invention provides a mining method for double-layer ultra-thin jade ore block cutting and push-out ore, specifically: firstly, the ore body is divided into ore blocks along the direction and inclination, and the ore blocks are cut to form a mining space after mining, using chain arms The saw cuts the upper ore body and surrounding rock horizontally and vertically along the working roadway, so that the ore body is cut into regular small ore blocks and separated from the upper and lower surrounding rocks; Squeeze the ore body down to make the root of the ore body break to realize the separation of ore and rock, and remove the separated ore body and transport it out by a flatbed truck; use the same cutting process to mine the lower layer of ore body; use a chain arm saw to cut the surrounding rock along the roof, Pushing bags are placed in the space formed after the cutting seam and the ore body are mined to squeeze and break the surrounding rock, and then transport it ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com