Atomizer and electronic cigarette thereof

A technology for atomizers and e-cigarettes, applied in tobacco, smoker supplies, applications, etc., can solve problems such as reduced user experience, leakage of e-liquid, and inability to fill e-cigarettes with the atomizer, so as to reduce the possibility of bacterial infection performance, reduced overall size, and easy portability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

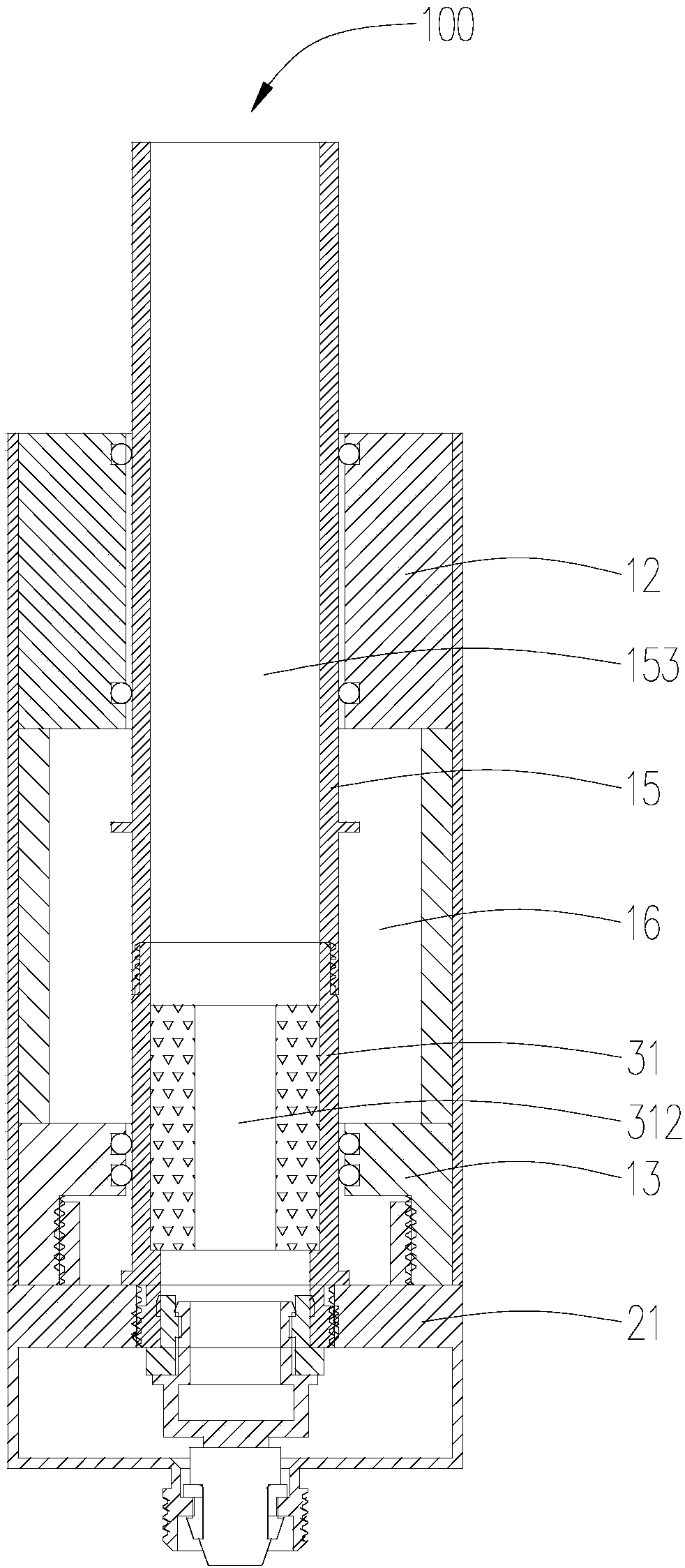

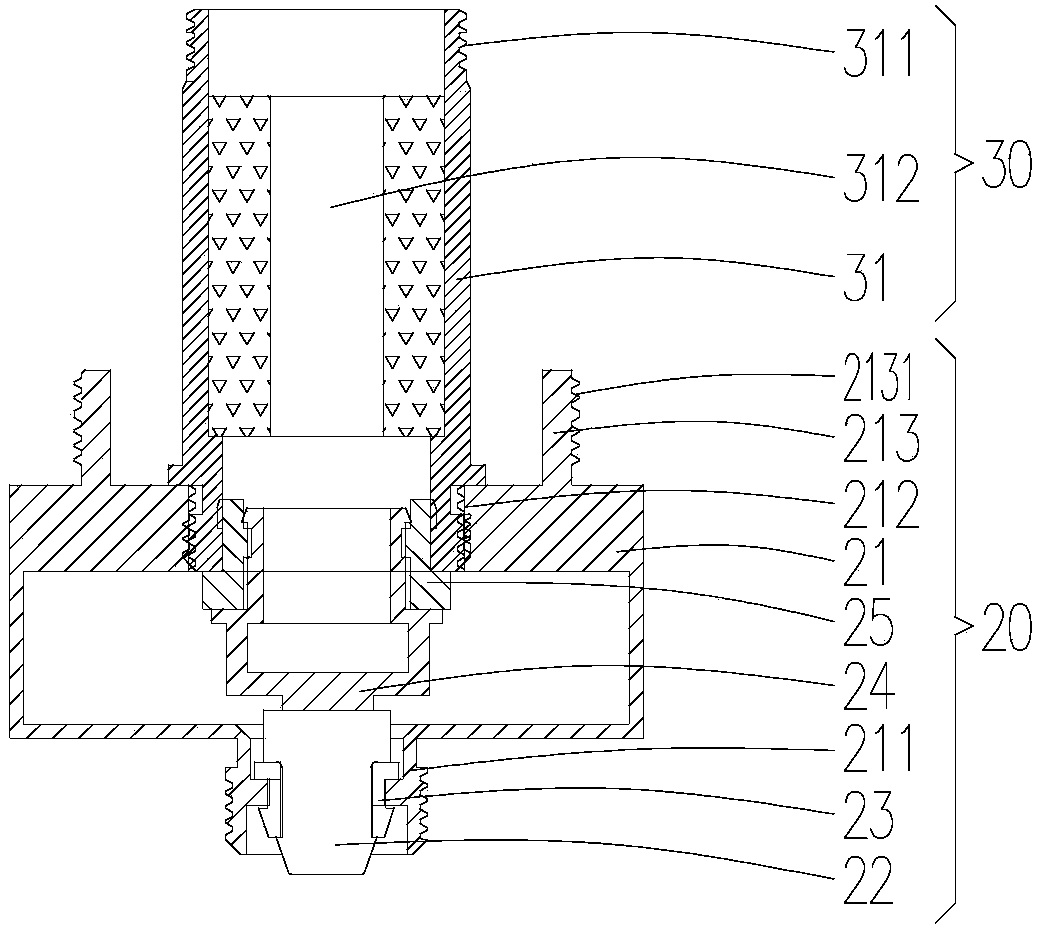

[0055] see Figure 4 Embodiment 1 of the present invention provides an electronic cigarette, which includes an atomizer 100 and a battery assembly (not shown) electrically connected to the atomizer 100 . The atomizer 100 includes a cartridge 10 , a base assembly 20 detachably disposed on one end of the cartridge 10 , and an atomizing head 30 detachably disposed on the base assembly 20 . The battery assembly is detachably connected to the base assembly 20 . When the base assembly 20 is connected to the pod 10, the smoke liquid in the pod 10 can enter the interior of the atomizing head 30, and under the electric drive of the battery component, the atomizing head 30 heats the smoke liquid and makes the smoke liquid mist Turn into smoke for users to use.

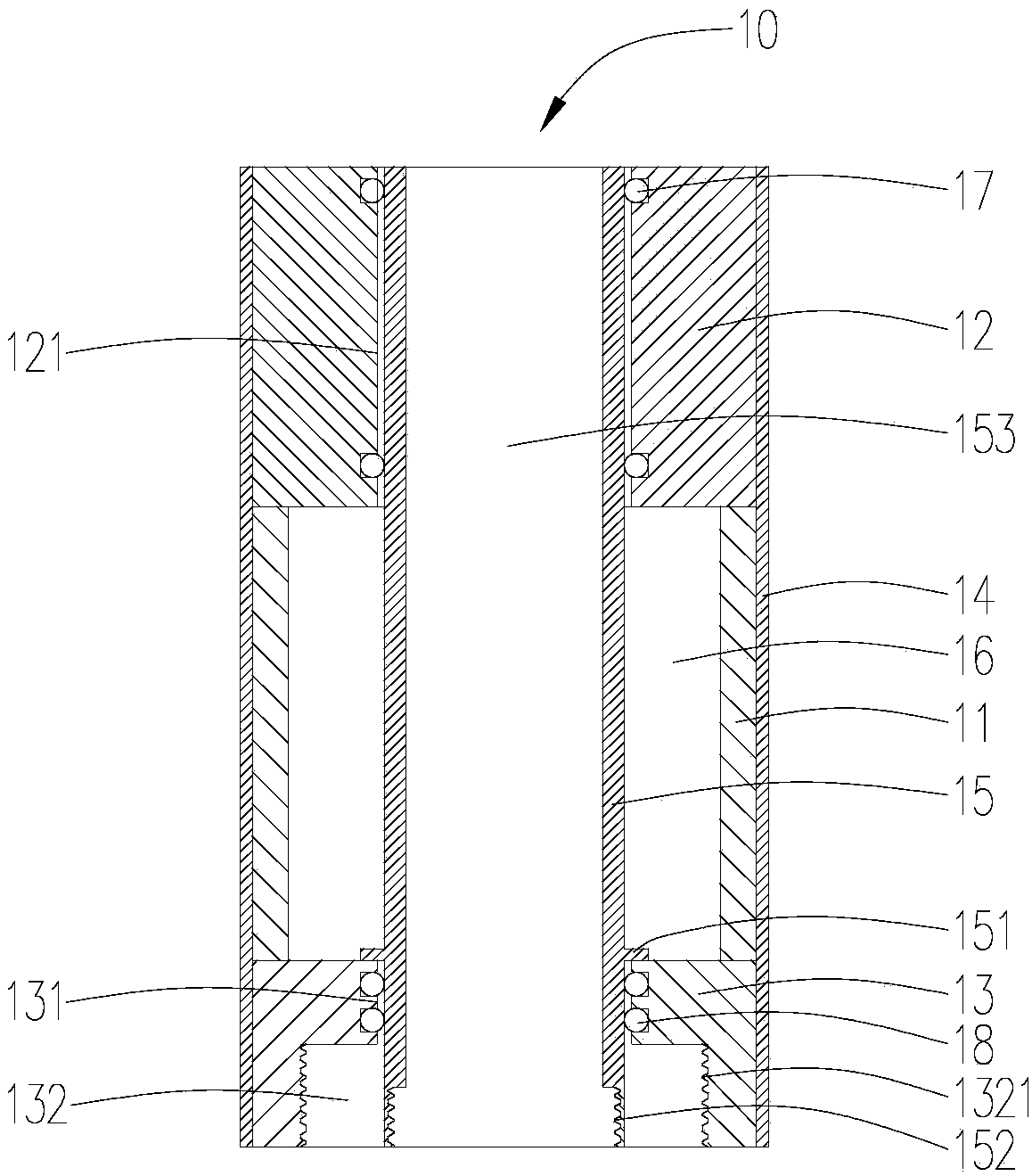

[0056] Specifically, see figure 2, The cartridge 10 includes a liquid storage tube 11 , an upper cover 12 , a lower cover 13 , an outer sleeve 14 and a flue 15 .

[0057] The upper cover 12 is fixed on one end of the liquid ...

Embodiment 2

[0089] see Figure 5 The difference between the atomizer provided in Embodiment 2 of the present invention and the atomizer 100 in Embodiment 1 is that when the flange 151 of the upper flue 15 of the pod 10 is against the lower cover 13, the upper side of the flue 15 is farther away from the lower cover. One end of the cover 13 can extend to the end of the upper cover 12 away from the lower cover 13 , and the protruding part of the flue 15 forms an extension 154 , and the length of the extension 154 is much smaller than the length of the flue 15 itself.

[0090] Before the flue 15 is connected to the atomizing sleeve 21, an external force can be applied to the protruding part 154 of the flue 15, such as pressing the protruding part 154, so that the gap between the flue 15 and the atomizing sleeve 21 connections, improving assembly reliability. The length of the protruding portion 154 is much smaller than the length of the flue 15 itself, so as to reduce the possibility of bac...

Embodiment 3

[0093] see Figure 6 and Figure 7 The difference between the atomizer 300 provided in Embodiment 3 of the present invention and the atomizer 100 in Embodiment 1 is that the cartridge 10 also includes an elastic member 19 arranged on one side of the flue 15 , and the atomizer head 30 is omitted. The second external thread 311 of the atomizing sleeve 31 is connected to the second internal thread 152 on the flue 15 . At this time, the connection mode between the atomizing sleeve 31 and the flue 15 is contact. In this embodiment, a positioning groove (not shown) is provided on the inner wall of the end of the flue 15 away from the upper cover 12, and a connecting portion matching the positioning groove is provided on the end of the atomizing sleeve 31 away from the base 21 (not shown in the figure), when connecting, the connecting portion of the atomizing sleeve 31 is arranged in the positioning groove of the flue 15 to prevent misalignment when the atomizing sleeve 31 abuts aga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com