Solid dust aerosol generation device and method

An aerosol generation and dust technology, which is applied in the fields of environmental science and medicine, can solve problems such as environmental pollution, dust pollution, and aerosol extraction, and achieve the effects of ensuring accuracy and stability, compact device structure, and easy portability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

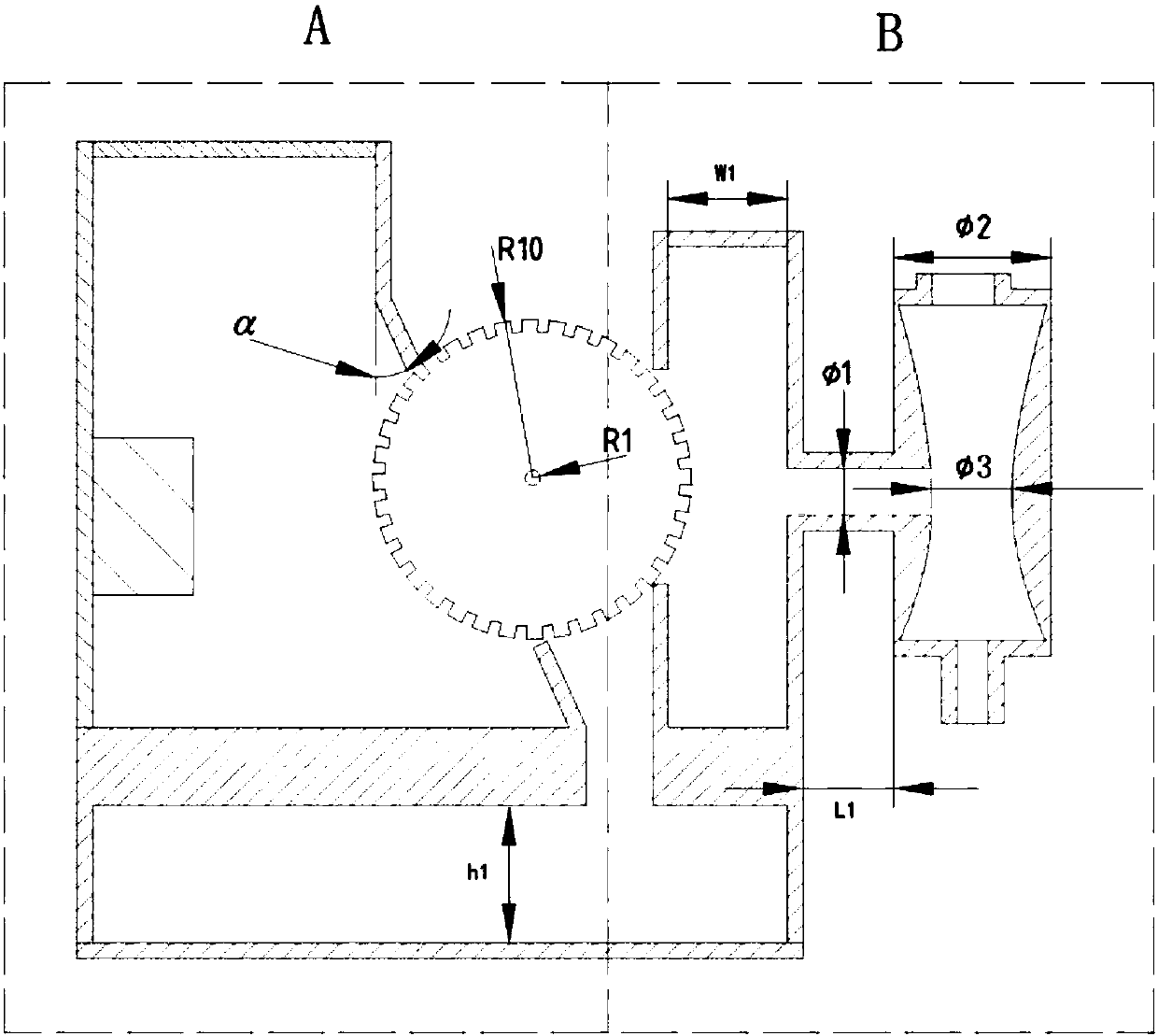

[0036] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

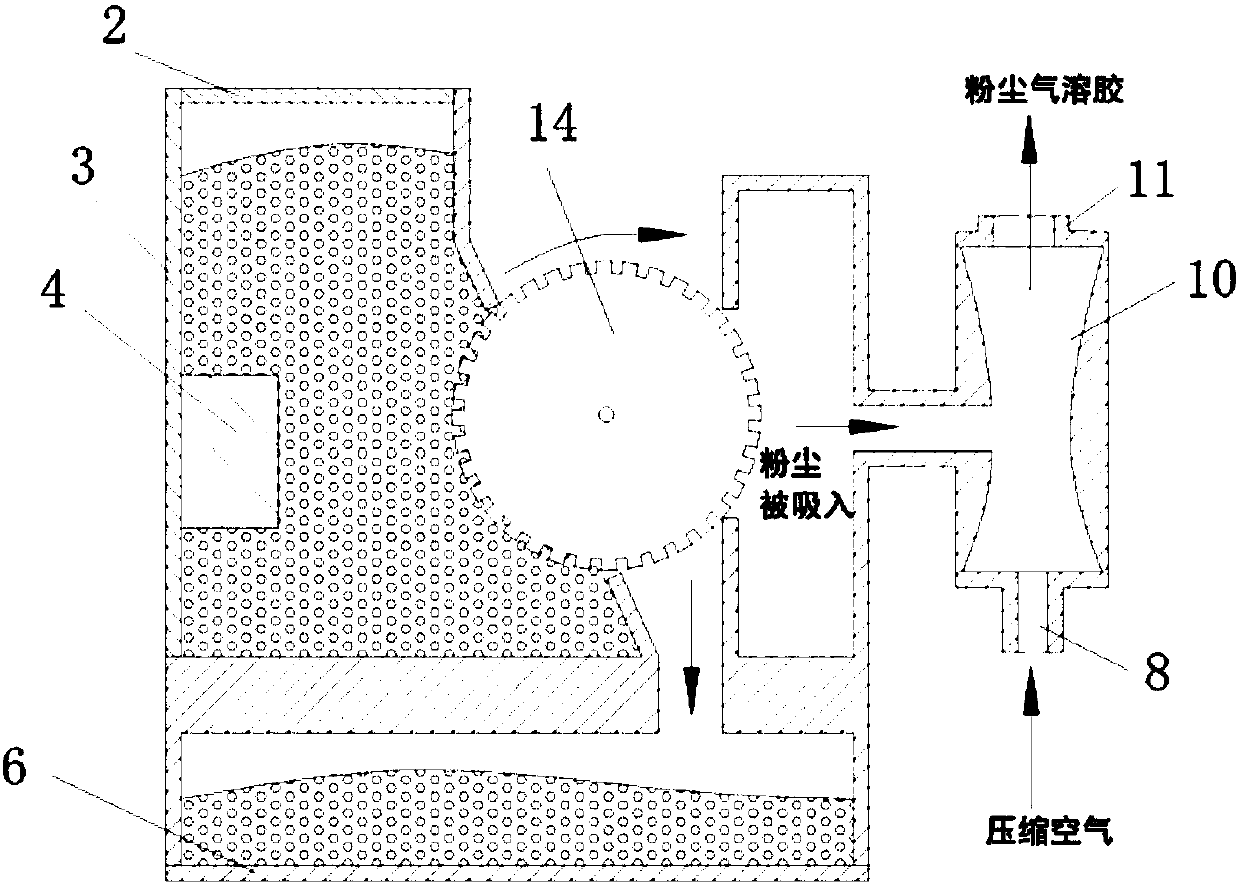

[0037] The present invention utilizes a deflection motor to fluidize the dust in the ash storage chamber so that it can be dispersed and evenly distributed without forming agglomerates; the dust is transported by a rotating disk, which is simple in control, compact in structure and low in cost; The structure is simple, the aerosol has good uniformity and will not cause pollution due to positive pressure and reverse blowing; the structure has a certain sealing and anti-leakage design, even if the dust leaks, a corresponding recovery device is also designed. Specific examples are as follows.

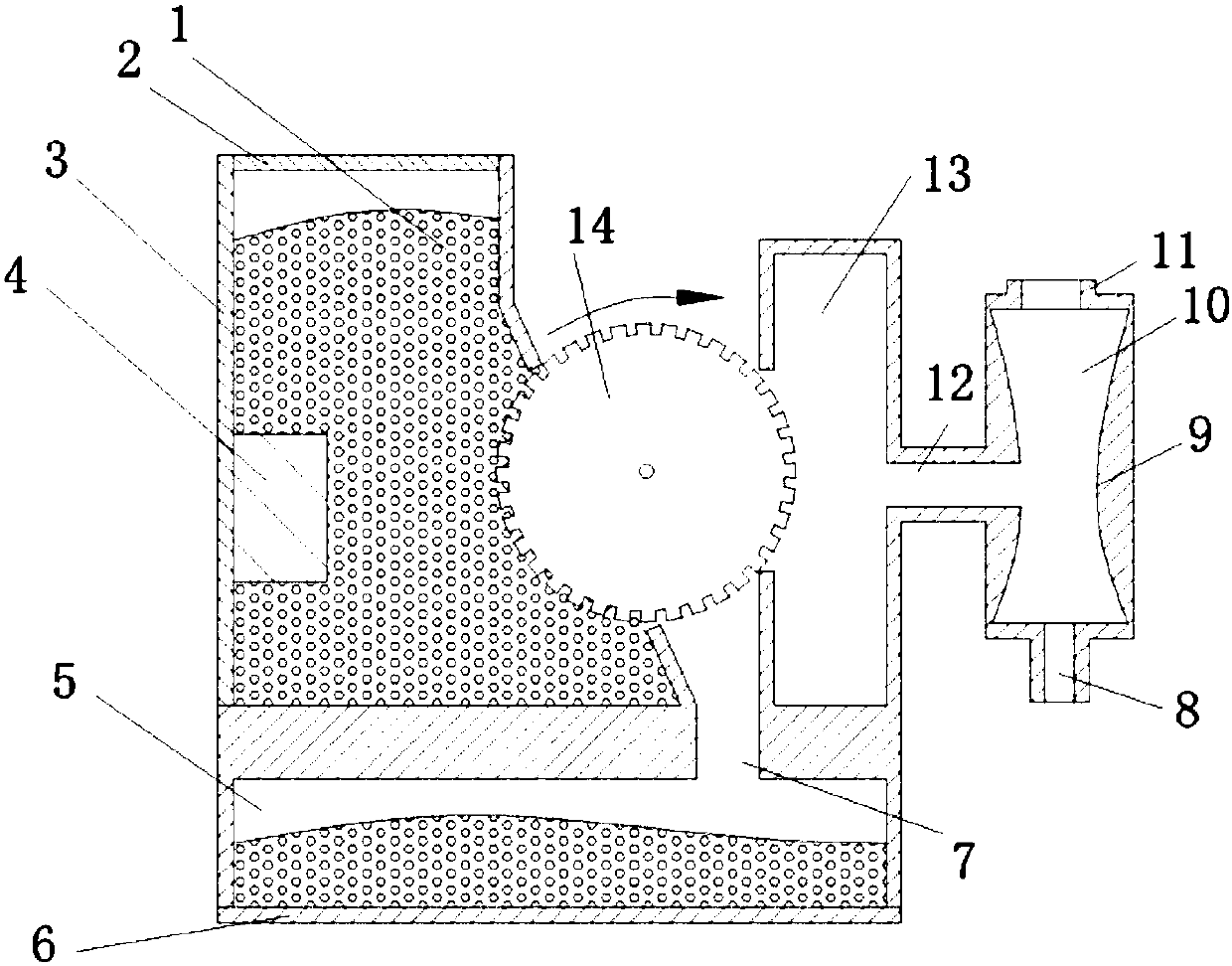

[0038] see figure 1, The solid dust aerosol generating device given in this embodiment includes: ash storage chamber 1, deflection motor 4, mixing chamber 13, recovery chamber 5, negative pressure generator 10, and rotating disk 14. The ash storage chamber 1 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com