Electrolysis system and electrolysis method for the same

A technology of electrolysis device and diaphragm, applied in the direction of electrolysis components, electrolysis process, chemical instruments and methods, etc., can solve problems such as disadvantages, and achieve the effect of suppressing the rise of electrolysis voltage, stabilizing electrolysis operation for a long time, and suppressing deposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

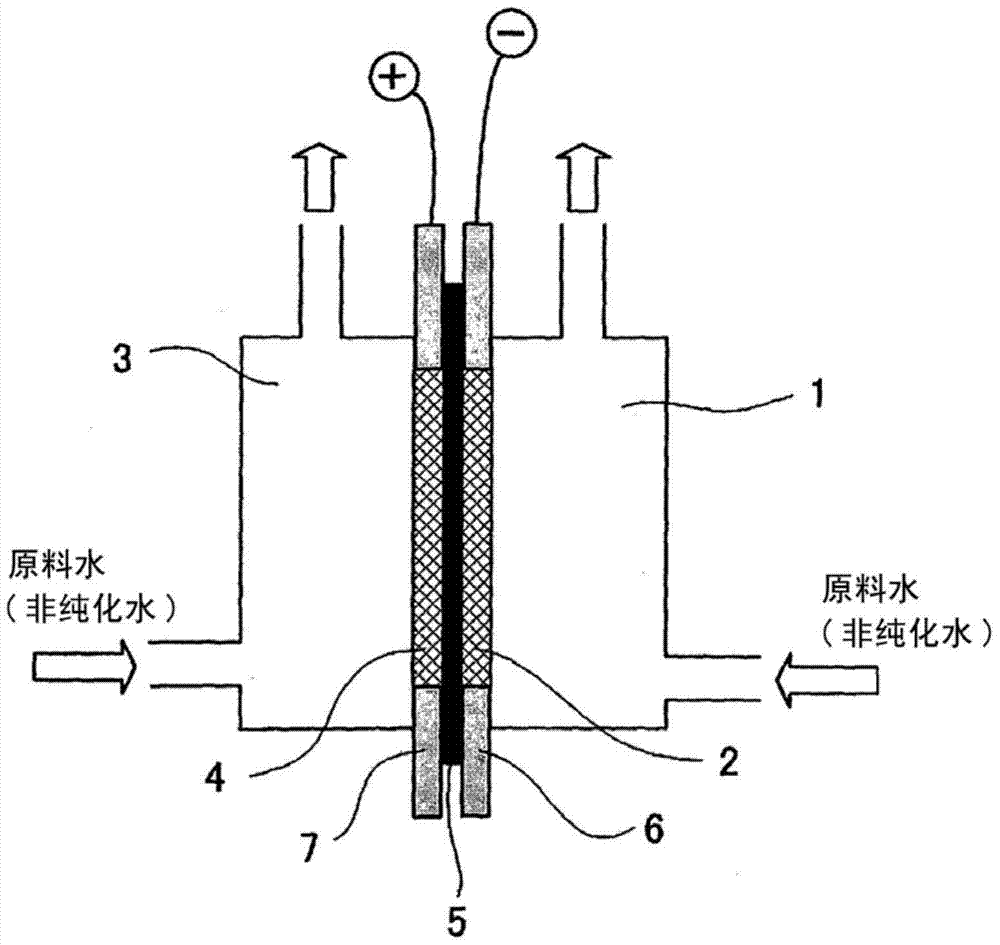

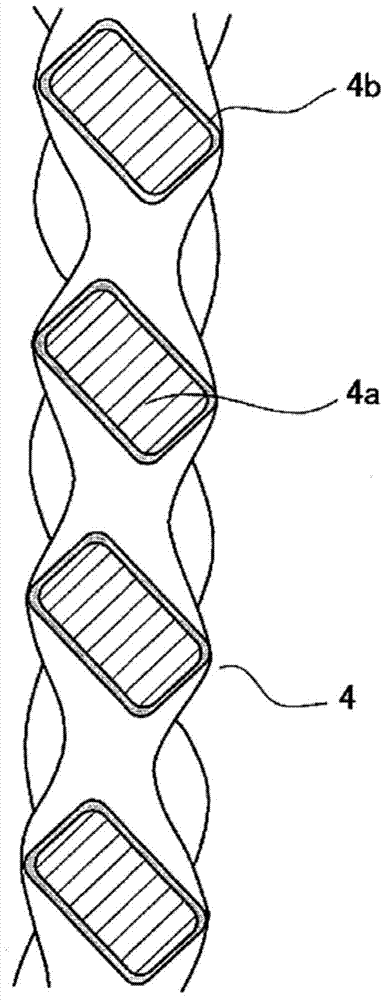

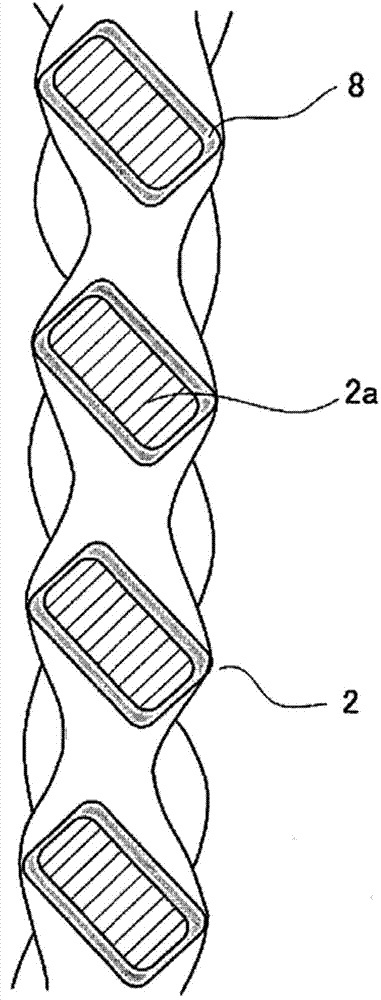

[0080] In Example 1, an SPE type electrolytic cell (SPE is a registered trademark of Permelec Electrode Ltd.) was used as a solid polymer electrolyte type electrolytic device as figure 1 An example of a two-chamber electrolysis device is shown. For the anode base material 4a and the cathode base material 2a, a SUS304 screen with a size of 30mm×30mm expanded metal is used (screen size: sheet thickness 1mm, SW3.5mm, and specific surface area 1.1m 2 / m 2 ).

[0081] A commercially available 5% dispersion of cation exchange resin (trade name: Nafion (registered trademark) DE520—Nafion is a registered trademark of EI du Pont de Nemours and Company) is applied to the parts other than the connection part with the current-carrying member 6 The substantially entire surface of the cathode 2 is then baked at 170 degrees Celsius, whereby the substantially entire surface of the cathode 2 is coated with an alkaline earth metal antifouling film 8 containing cation exchange resin. In addition, ...

Embodiment 2

[0094] In Example 2, use such as image 3 The diaphragm electrolysis device shown. For Cathode 2 and Anode 4, a Ti screen with a size of 16mm×16mm is used (screen specifications: sheet thickness 1mm, SW3.5mm and specific surface area 1.1m 2 / m 2 ). A commercially available 5% dispersion of cation exchange resin (trade name: Nafion (registered trademark) DE520—Nafion is a registered trademark of EI du Pont de Nemours and Company) was applied to substantially the entire surface of the cathode 2, and then Bake at 150 degrees Celsius, thereby forming an alkaline earth metal antifouling film 8 containing cation exchange resin. The cathode 2 and the anode 4 are arranged in parallel at an interval of about 1.5 mm, and are separated by a hydrophilic porous membrane 9 (neutral membrane) of 20 mm×20 mm. These were installed in the center of the cathode chamber 1 and the anode chamber 3 of the diaphragm electrolysis apparatus.

[0095] Tap water was supplied to the anode chamber 3 and the...

Embodiment 3

[0101] In Example 3, use such as Figure 4 The three-chamber electrolysis device shown. The three-compartment electrolysis apparatus includes the anode 4 and the cathode 2, the anion exchange membrane 10 (trade name: TOSFLEX SF48-registered trademark of Tosoh Corporation) as the diaphragm of the anode compartment 3 and the intermediate compartment 12 prepared as in Example 1, and the intermediate compartment 12 and The cation exchange membrane 11 between the cathode chambers 1 (trade name: Nafion117-registered trademark of EI du Pont de Nemours and Company). This structure is a device that simulates a production device that uses brine as a raw material to produce so-called strong acidic water containing hypochlorous acid in the anode chamber 3 and alkaline ionized water in the cathode chamber.

[0102] The diluted brine maintained at 30 g / L was circulated and supplied to the intermediate chamber 12 of the electrolytic cell, and tap water was supplied to the anode chamber 3 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com