Sound adjustable device for coupling to an engine and method for manufacturing thereof

a technology of adjustable device and engine, which is applied in the direction of engine components, machines/engines, mechanical apparatus, etc., can solve the problems of increasing the amount of exhaust-noise, and achieve the effect of increasing or decreasing the sound volume of exhaust-noise, increasing or decreasing the air flow to the carburetor 29

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

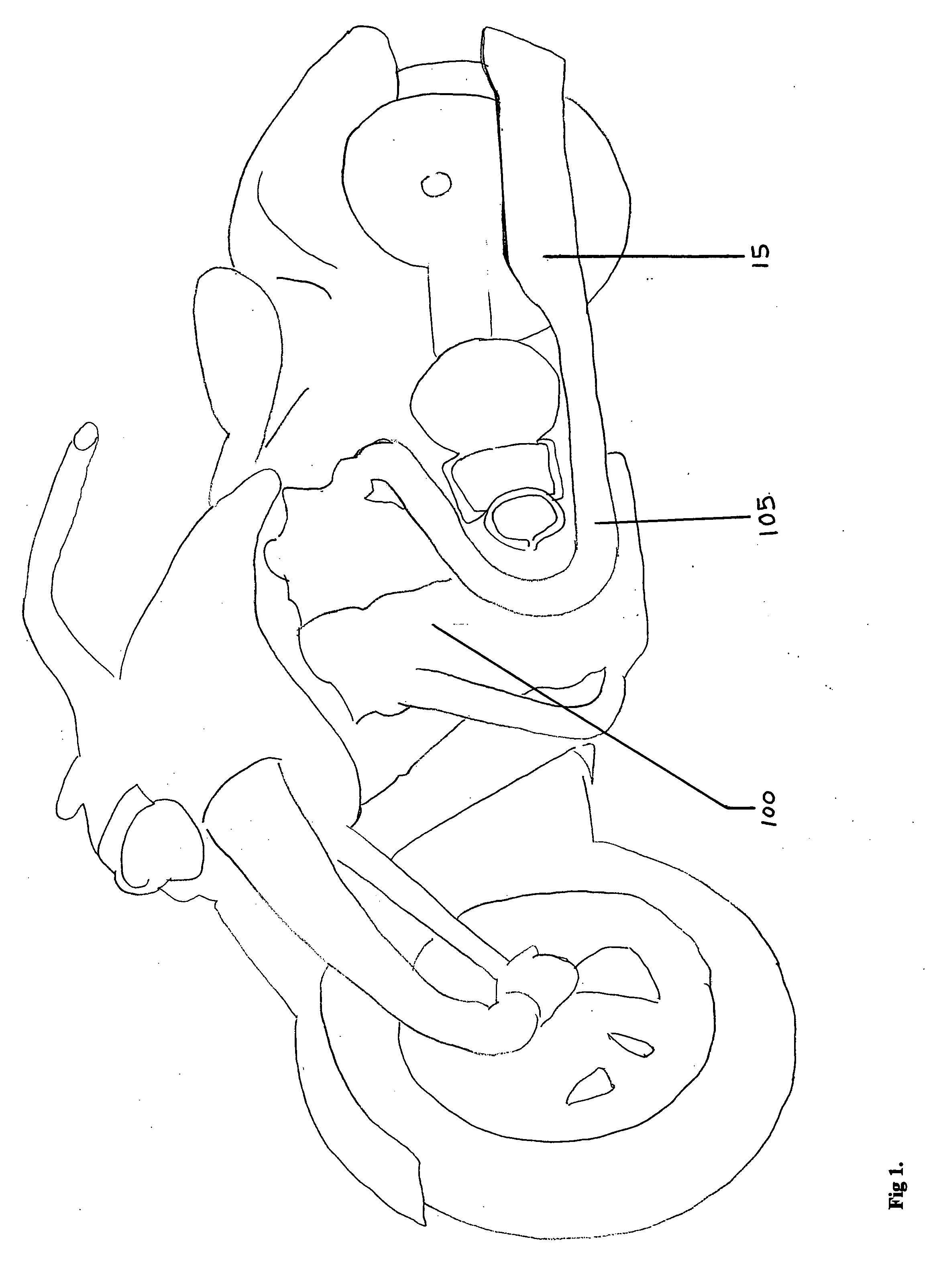

[0049]FIG. 1 is an oblique view of a motorcycle with an internal combustion engine 100, wherein exhaust pipe 105 directs exhaust and exhaust-noise from the internal combustion engine 100 to a conventional muffler 15, thereby dampening the exhaust-noise.

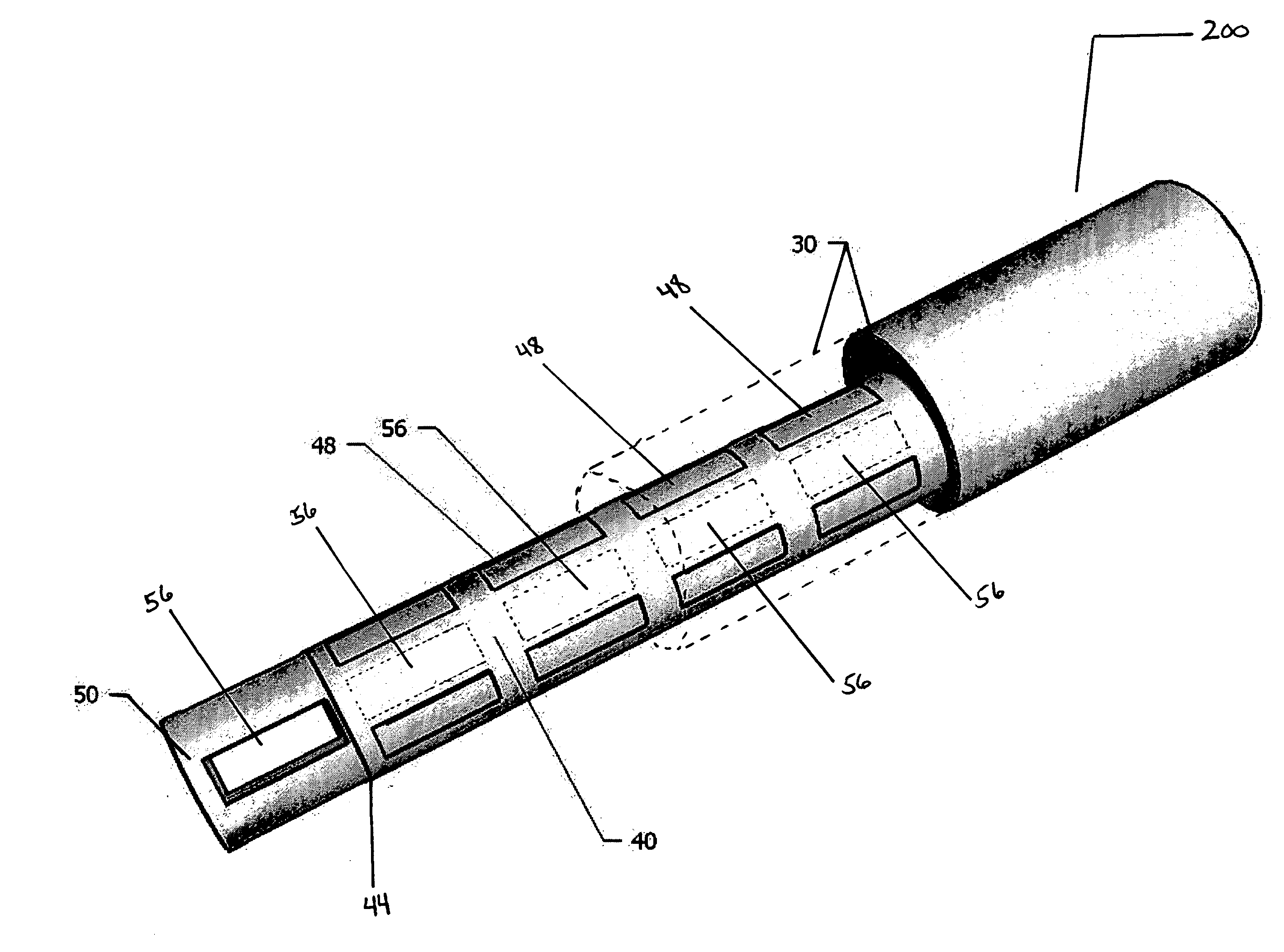

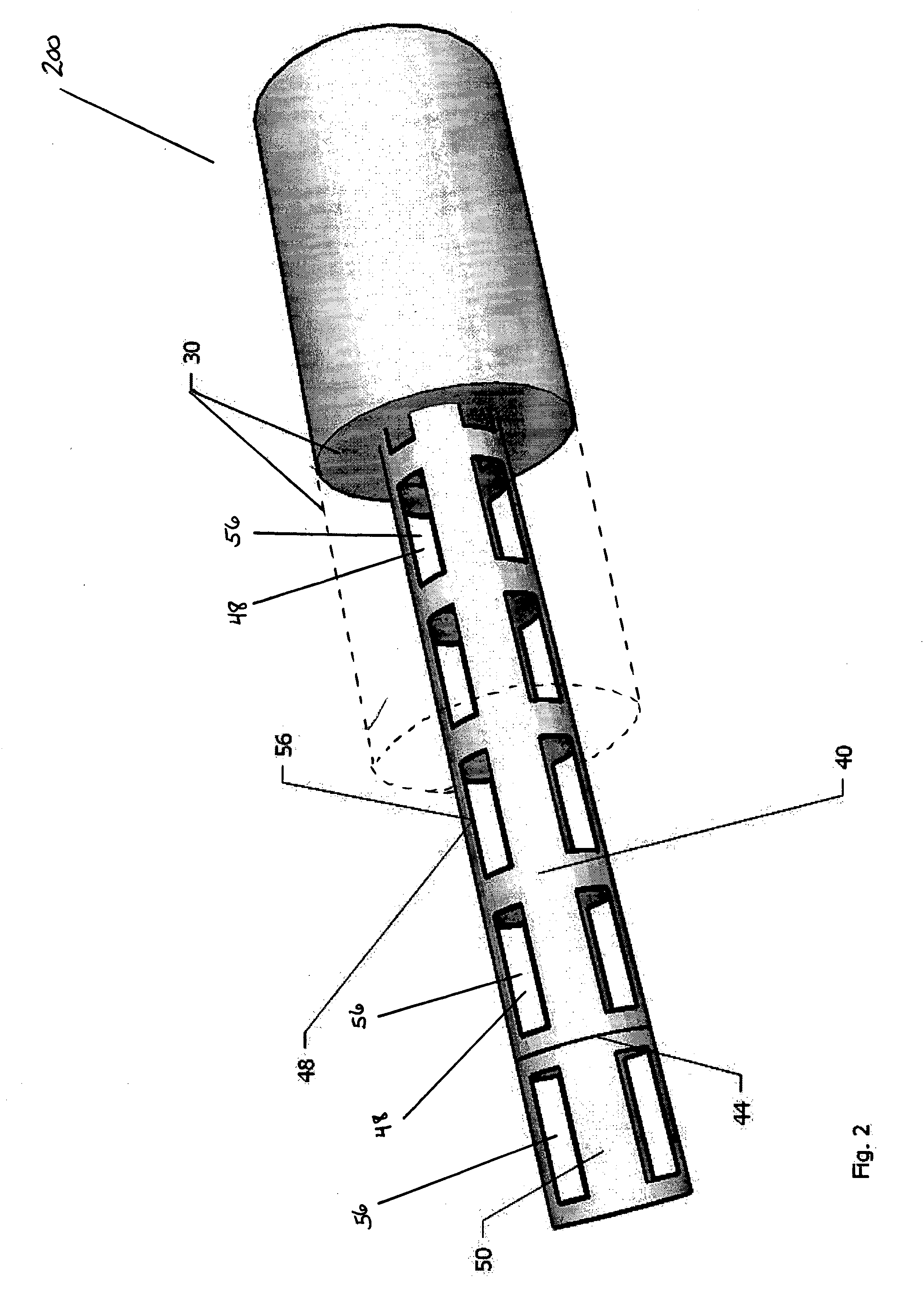

[0050]FIG. 2 is an oblique partially cut-away view of a sound adjustable device 200 in accordance with an embodiment, positioned for a maximal sound-dampening effect. The inner slotted pipe 50 is at least partially contained within the outer slotted pipe 40, wherein the combination of slotted pipes 40 and 50 are at least partially surrounded by a sound-dampening material 30. The inner slotted pipe 50 includes at least one second slot 56, and the inner slotted pipe 50 protrudes from the outer slotted pipe 40 at the opening 44 of the outer slotted pipe 40. The outer slotted pipe 40 includes at least one first slot 48, and the slotted pipes 40 and 50 are movable with respect to each other, either by rotation or by sliding. As the slotte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com