Super retarded concrete

A concrete and ultra-retarded setting technology, applied in the field of concrete, can solve the problems that concrete cannot adapt to construction conditions, etc., and achieve the effects of prolonging the initial setting time, increasing strength and improving durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

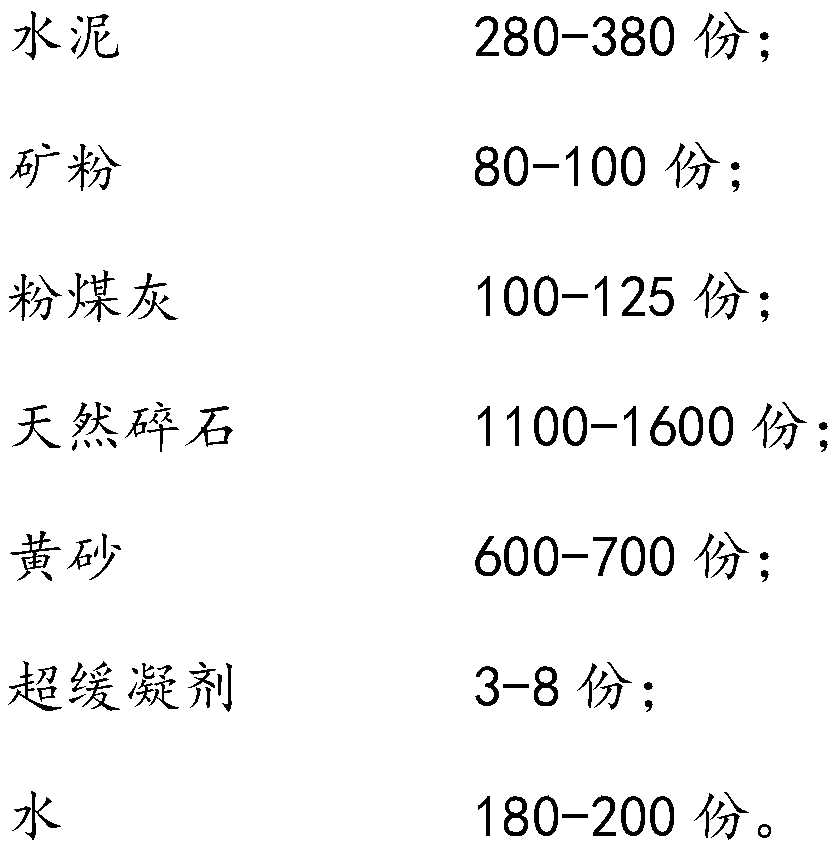

[0032] The invention discloses a super retarded concrete, which comprises the following raw materials in parts by weight:

[0033]

[0034]

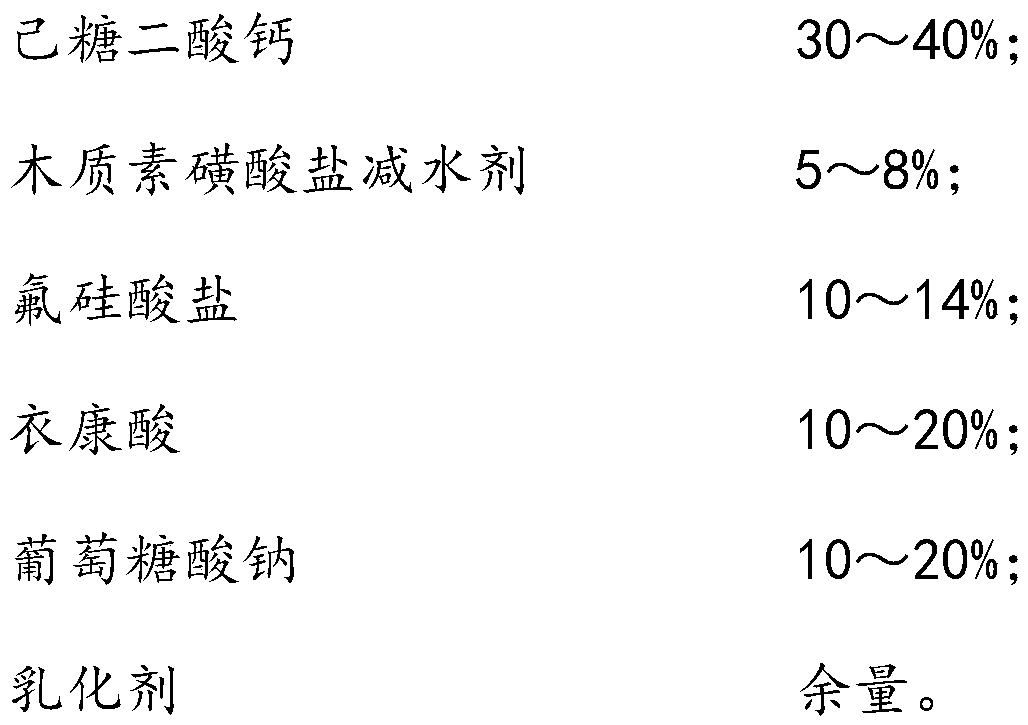

[0035] Wherein, super retarder comprises the following components by weight percentage:

[0036]

[0037] The emulsifier in the super retarder is OP-40 emulsifier.

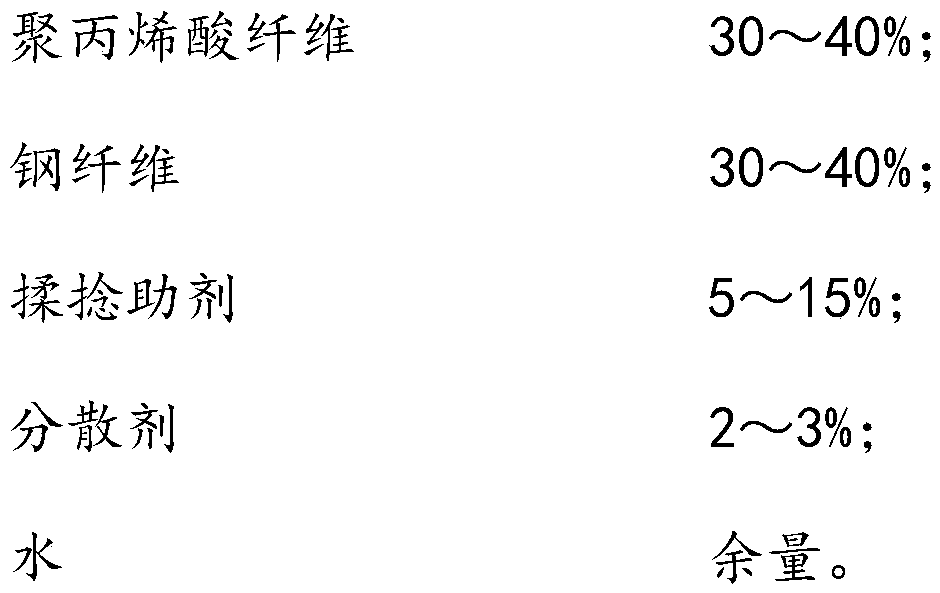

[0038] In terms of weight percentage, the reinforcing agent raw materials include 30% polypropylene fiber, 30% steel fiber, 5% rolling aid, 5% self-repairing microcapsule, 2% dispersant, and 28% water, wherein the rolling aid includes silane coupling Agent 30%, OP-40 emulsifier 10%, epoxy resin 5%, butyl acetate 55%. The core material of the self-healing microcapsule is epoxy resin core material; the wall material is urea-formaldehyde resin.

[0039] The reinforcing agent production steps are as follows: knead the polypropylene fiber and the steel fiber by using a texturing machine, and spray the mixed solution of kneading aid, self-repairing microcapsule, dispers...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com