Method for repairing heat damage crackles of ceramic based composite material

A composite material and thermal damage technology, which is applied in the field of repairing thermal damage cracks of ceramic matrix composite materials, can solve the problems that cracks cannot be completely removed and repaired, the oxidation kinetic curve fluctuates greatly, and the grinding process is difficult to effectively control. To achieve the effect of improving the anti-oxidation ability, increasing the bending strength and restoring the anti-oxidation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

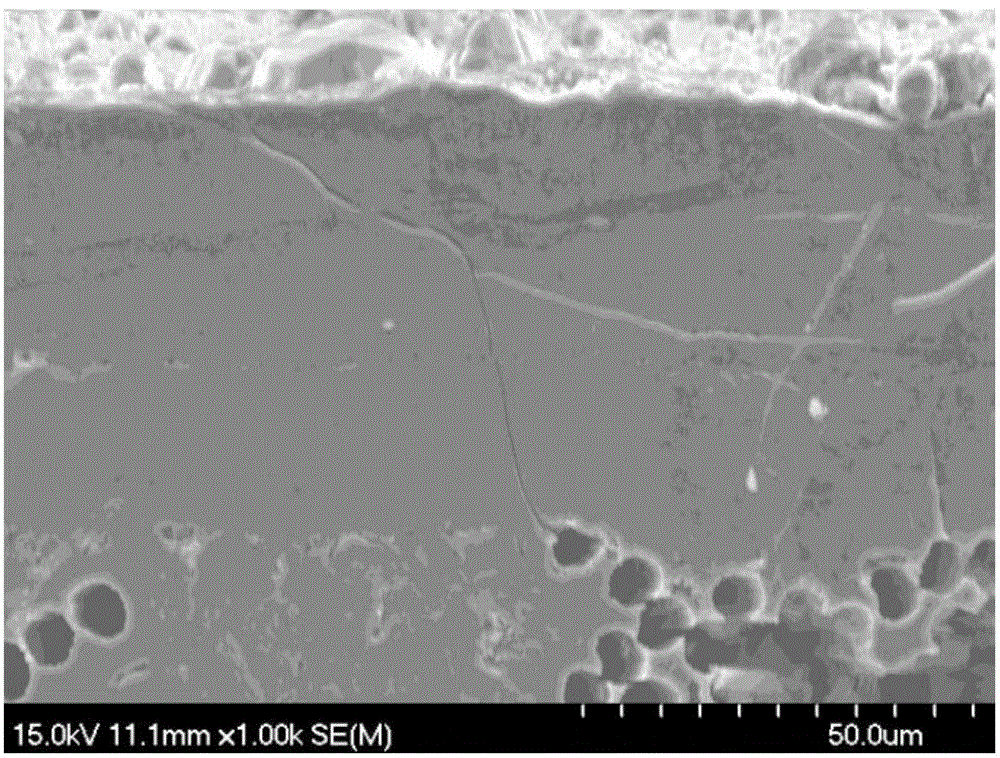

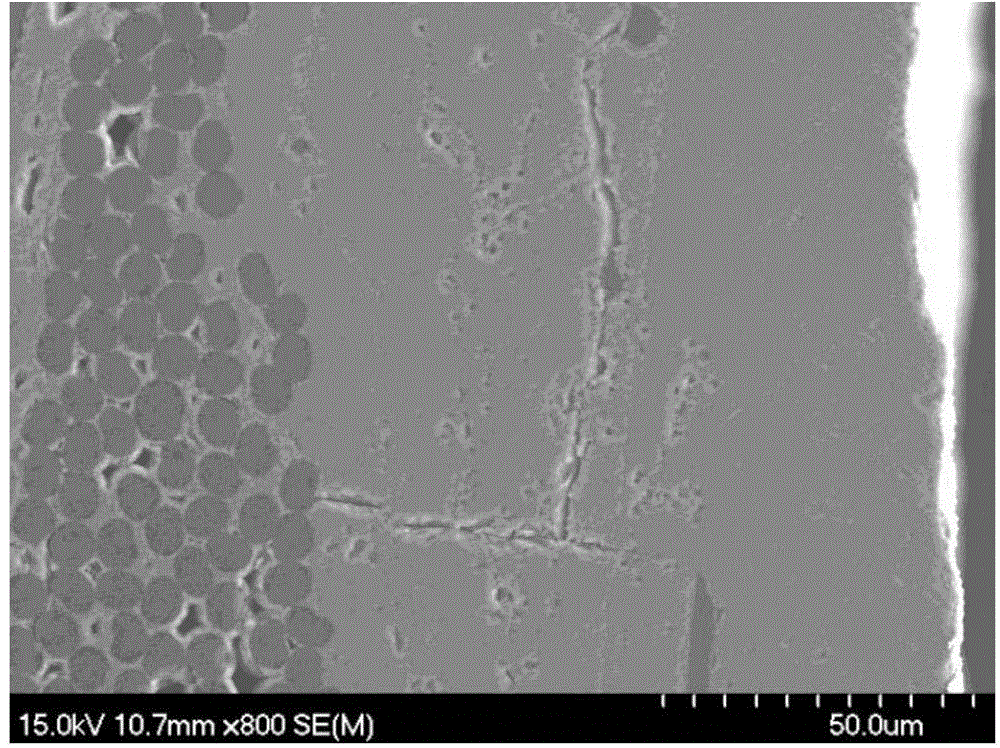

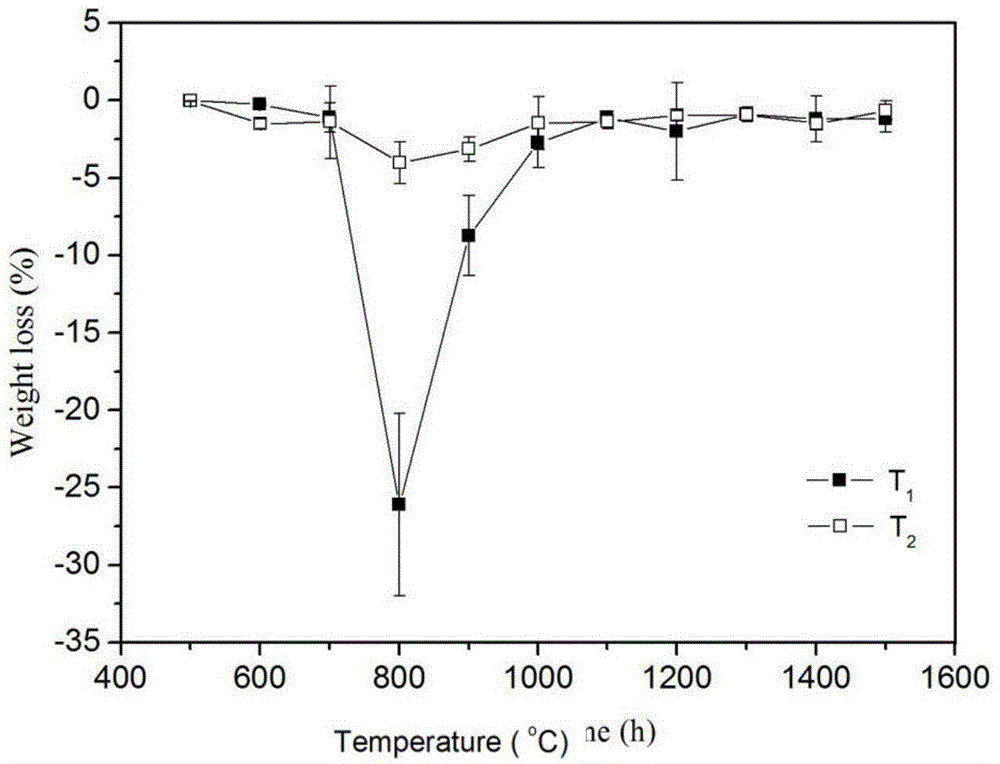

[0026] Example 1: Repair of sample preparation cracks.

[0027] (1) Two-dimensional carbon fiber cloth is laminated in the same direction to obtain a two-dimensional (2D) laminated fiber preform.

[0028] (2) The fiber preform in (1) is deposited with a PyC interfacial layer with a thickness of about 200 nm. The process conditions are: deposition temperature 800-1000°C, Ar gas flow 150-200ml / min, C 3 h 6 The gas flow is 150-250ml / min, and the deposition time is 72h.

[0029] (3) The preform obtained in (2) is subjected to chemical vapor deposition (CVD) SiC matrix, and the process conditions are: deposition temperature 800-1000°C, pressure 2-4kPa, H 2 Gas flow 150-250ml / min, Ar gas flow 250-350ml / min, trichloromethylsilane temperature 25-35℃, H 2 The molar ratio to MTS is 8-12, and the deposition time is six heats, 120 hours each time. Obtain the original sample master.

[0030] (4) Grind the surface of the sample master plate prepared in (3) with a grinding wheel, open ...

Embodiment 2

[0033] Example 2: Repair of thermally damaged cracks in the sample.

[0034] (1) Two-dimensional carbon fiber cloth is laminated in the same direction to obtain a two-dimensional (2D) laminated fiber preform.

[0035] (2) The fiber preform in (1) is deposited with a PyC interfacial layer with a thickness of about 200 nm. The process conditions are: deposition temperature 800-1000°C, Ar gas flow 150-200ml / min, C 3 h 6 The gas flow is 150-250ml / min, and the deposition time is 72h.

[0036](3) The preform obtained in (2) is subjected to chemical vapor deposition (CVD) of the SiC substrate, and the process conditions are: deposition temperature 800-1000°C, pressure 2-4kPa, H 2 Gas flow 150-250ml / min, Ar gas flow 250-350ml / min, trichloromethylsilane temperature 25-35℃, H 2 The molar mass ratio to MTS is 8-12, and the deposition time is six heats, 120 hours each time. Obtain the original sample master.

[0037] (4) Grind the surface of the sample master plate prepared in (3) w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com