Concrete bottom coating of concrete work protection polyurea material

A technology for concrete and polyurea, applied in the direction of polyurea/polyurethane paint, coating, filling slurry, etc., can solve the problem of poor effect in humid environment, and achieve the effects of superior performance, convenient use and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

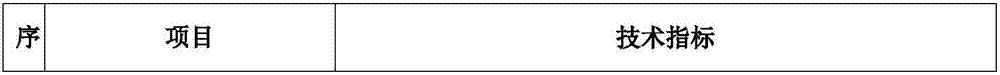

Examples

Embodiment 1

[0030] A concrete primer of a hydraulic protection polyurea material, the A component material consists of 43 parts by weight of MDI-50, 43 parts of MDI-100, 76 parts of PPG-2000, 38 parts of PCDL-2000, 14 parts of KH-560, 86 parts of butyl acetate; the B component material is composed of 26.7 parts of MOCA, 31 parts of Unilink 4200, 2 parts of antioxidant 1076, and 90.3 parts of butyl acetate.

[0031] The concrete primer for preparing the described a kind of hydraulic protection polyurea material is characterized in that: it comprises the following process steps:

[0032] Step 1: Preparation of component A materials: Weigh the above-mentioned polyol by weight, add the polyol into the container, turn on the agitator; heat to 110-120°C, and vacuum it with a vacuum pump, and the vacuum degree is -0.1-- Dehydration at 0.08MPa to remove the raw material water until the moisture content of the raw material drops to less than or equal to 3 / 10,000; cool the temperature of the liquid...

Embodiment 2

[0036] A concrete primer of a hydraulic protection polyurea material, the A component material consists of 43 parts by weight of MDI-50, 43 parts of MDI-100, 76 parts of PPG-2000, 38 parts of PCDL-2000, 14 parts of KH-560, 86 parts of butyl acetate; the B component material is composed of 35.5 parts of MOCA, 20.5 parts of Unilink 4200, 2 parts of antioxidant 1076, and 92 parts of butyl acetate.

[0037] Its preparation method is identical with embodiment 1.

Embodiment 3

[0039] A concrete primer of a hydraulic protective polyurea material, the A component material consists of 70 parts by weight of TDI, 130 parts of PPG-1000, 20 parts of KH-550, 110 parts of butyl acetate; The B component material is composed of 40 parts by weight of Desmophen NH 1420, 4 parts of antioxidant 245, and 80 parts of ethyl acetate.

[0040] Its preparation method is identical with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| peel strength | aaaaa | aaaaa |

| Strength retention | aaaaa | aaaaa |

| Strength retention | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com