Method for adopting laser fuse wires for repairing mold

A laser cladding and mold technology, applied in the field of mold processing, can solve the problems of waste and low mold life, and achieve the effects of low cost, crack repair and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

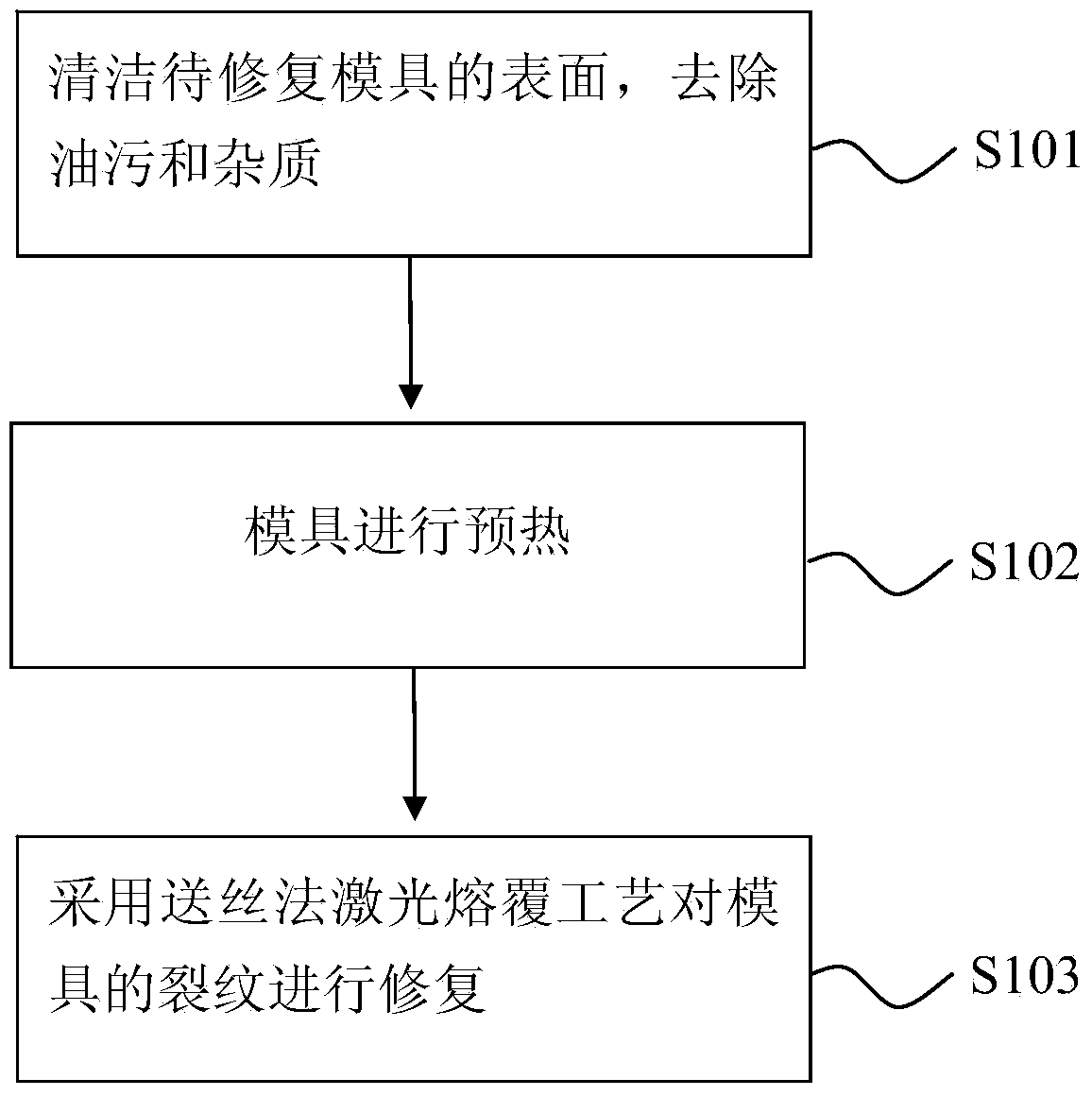

[0023] figure 1 The schematic diagram of the technological process of adopting the method for repairing mold with laser fuse provided in this embodiment, the material of mold described in this embodiment is 5CrNiMo steel material; The method comprises steps:

[0024] S101, cleaning the surface of the mold to be repaired, removing oil and impurities;

[0025] S102. Preheating the mold, using a heating coil to preheat the mold;

[0026] S103. The cracks of the mold are repaired by using the wire-feeding laser cladding process, the laser spot is irradiated on the cracks of the mold, and the fed laser welding wire is clad on the cracks to repair the mold; wherein, laser cladding uses The welding wire is SKD11, the diameter is 0.6mm; the wire feeding direction is opposite to the moving direction of the mold, the angle between the wire feeding direction and the mold surface is 30°, the wire feeding speed is 3mm / s, and the mold moving speed is 1.5mm / s ;The laser power is 600W, and ...

Embodiment 2

[0030] The difference from Example 1 is that in this example, some parameters were changed in the laser cladding process steps, as follows:

[0031] In step S103, the welding wire used for laser cladding is SKD11 with a diameter of 0.8mm; the wire feeding direction is opposite to the moving direction of the mold, the angle between the wire feeding direction and the mold surface is 20°, and the wire feeding speed is 5mm / s , the moving speed of the mold is 2mm / s; the laser power is 700W, and the size of the laser spot is 6mm; among them, in the cladding repair process, the side-blowing protective inert gas is used for protection, and the direction of the inert gas injection is related to the wire feeding The direction of the injection of inert gas is the same as that of the mold surface at an angle of 50°, and the flow rate of the injection protection gas is 20L / min; among them, the size of the mold crack is about 0.6mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com