Reparative conductive adhesive and preparation method thereof

A conductive adhesive and restorative technology, which is applied in the field of conductive adhesive, can solve the problems of low repair rate, poor conductivity of microcapsules, and difficult preparation of microcapsules, and achieve the effect of simple process and easy control of parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~6

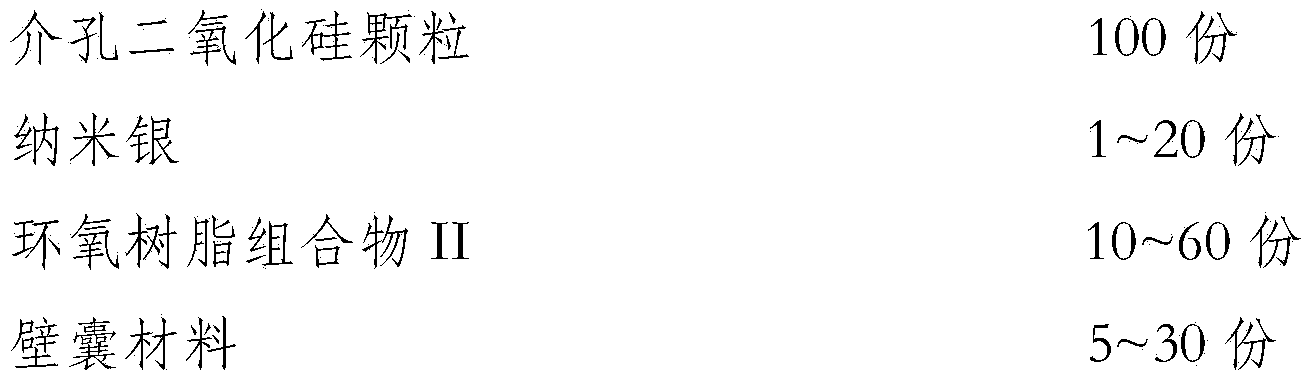

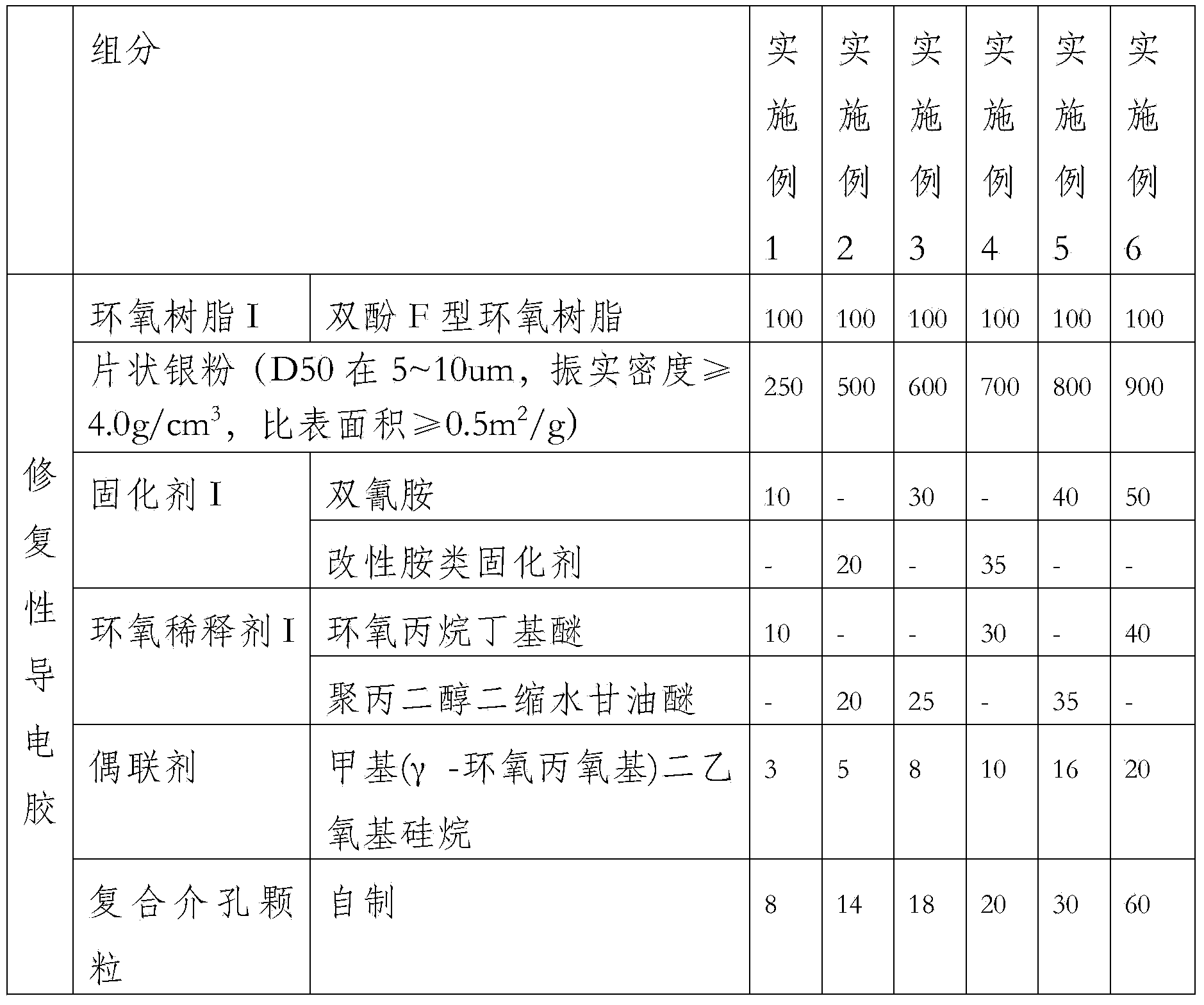

[0039] The present invention is a kind of restorative conductive adhesive, and its composition comprises: Epoxy resin I, flaky silver powder, curing agent I, epoxy diluent I, coupling agent, and composite mesoporous particle, each parts by weight is shown in Table 1 shown. Wherein, the curing temperature of the epoxy resin composition I composed of the curing agent I, the epoxy resin I and the epoxy diluent I is 60-80°C. The coupling agent can be an organosilane coupling agent; the curing agent I can be dicyandiamide or a modified amine curing agent; the epoxy diluent I can be propylene oxide butyl ether or polypropylene glycol diglycidyl ether. Of course, the selection of the curing agent I and the epoxy diluent I only needs to satisfy the curing of the epoxy resin composition I at a temperature range of 60-80°C.

[0040] Table 1: The contents of each raw material component of the repairable conductive adhesive

[0041]

[0042] Wherein, the composite mesoporous particle...

Embodiment 1

[0054] In Example 1, what is added in step S3 is the pre-polymerized solution of melamine and formaldehyde copolymer obtained by the ratio of melamine, 37% formaldehyde and deionized water in a ratio of 1:1.5:1.6. In Example 2, what is added in step S3 is the pre-polymerization liquid of polyurea-formaldehyde resin obtained by the ratio of 1:1.5 between urea and 37% formaldehyde solution. In embodiment 3~6, what add in step S3 is methacrylic acid monomer, polyvinyl alcohol dispersant, ammonium persulfate initiator, compound emulsifier (OP-10 and sodium dodecylbenzene sulfonate by weight ratio 1:1 mixture), the weight ratio of deionized water, emulsifier, dispersant, initiator and monomer is 600~1800:8~12:0.5~1.5:0.1~0.3:100. Wherein, the selection of specific process parameters in steps S1-S3 is shown in Table 4.

[0055] Table 4: Specific process parameter table

[0056]

[0057]

[0058] The restorative conductive adhesive obtained in Examples 1-6 was cured at 60-80°...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com