Rare earth boronizing process for roller

A technology for rolls and rare earths is applied in the field of rare earth boron co-infiltration technology for rolls, which can solve the problems of low service life of the rolls, and achieve the effects of increasing service life, improving surface hardness and enhancing thermal fatigue resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

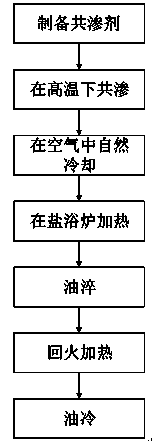

[0014] The steps of the rare earth boron co-infiltration process for the roll are as follows:

[0015] 1. According to the mass ratio of 5% tetraboron monocarbide, 10% potassium tetrafluoroborate, 5% charcoal, 5% cerium Ce rare earth compound and 75% silicon carbide, uniformly mix to obtain a co-infiltration agent;

[0016] 2. Co-infiltrate the 40Cr 40Cr steel roll in the rare earth boron infiltrating agent at 860 ° C for 4 hours, and then cool the 40Cr 40Cr steel roll naturally in the air;

[0017] 3. Place the 40Cr 40Cr steel roll in a salt bath furnace, heat it to 840°C, and keep it warm for 30 minutes;

[0018] 4. Take the 40Cr 40Cr steel roll out of the salt bath furnace and oil quench it;

[0019] 5. Temper and heat the 40Cr 40Cr steel roll again at 400°C for 1 hour;

[0020] 6. Put the 40Cr 40Cr steel roll into the oil until completely cooled.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com