Laser-cladding high temperature resistance abrasionproof structure for special-shaped water cooling wall tube bundle

A technology of laser cladding and water-cooled wall tubes, which is applied in the direction of combustion methods, combustion chambers, outer covers/linings, etc., can solve the problems of increased wear of water-cooled wall tubes, matrix deformation, and low hardness of the wear-resistant layer, so as to improve high temperature resistance Effects of anti-wear properties, improvement of surface Vickers hardness, and increase of oxidation resistance temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in detail below in conjunction with the accompanying drawings, so that those of ordinary skill in the art can implement it after referring to this specification.

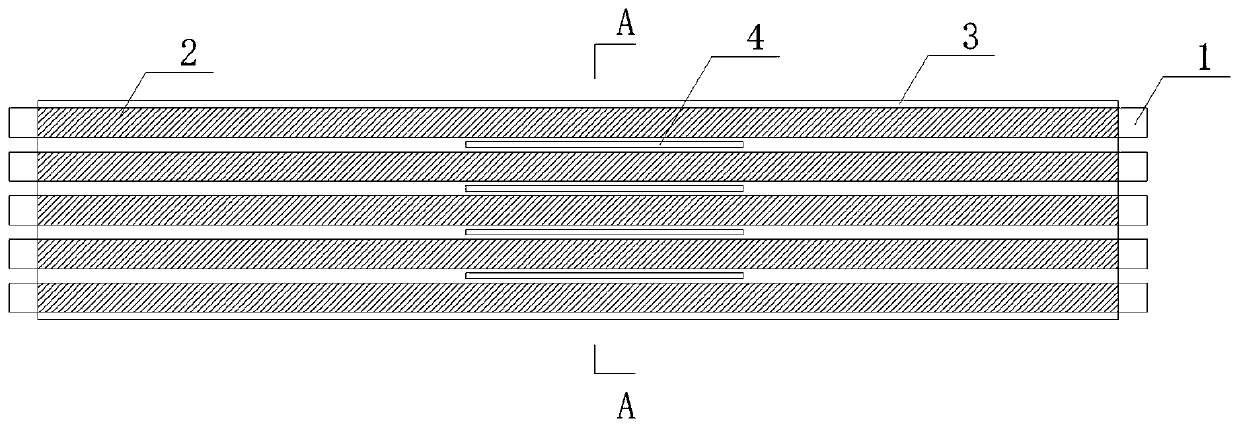

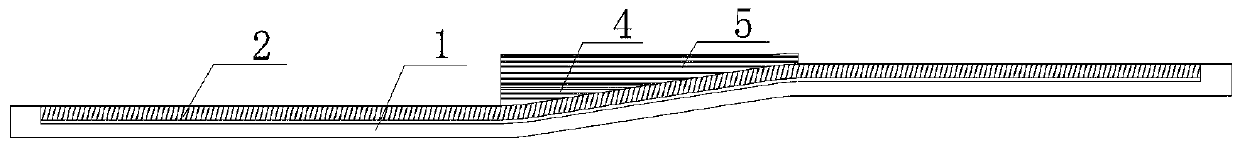

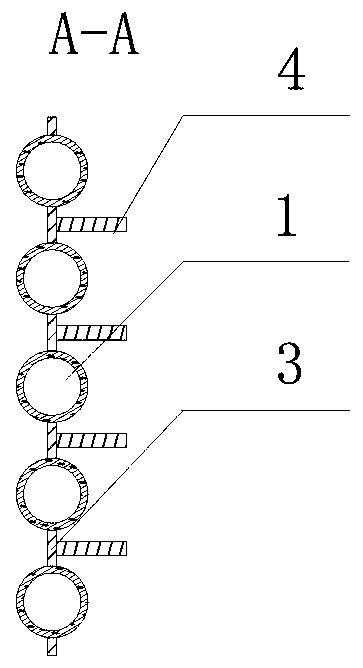

[0032] Such as Figure 1-Figure 3 As shown, a laser cladding high-temperature-resistant and wear-resistant structure for special-shaped water-cooled wall pipe rows includes: water-cooled wall pipe 1, which is provided with ceramic-metal composite material TiB 2 -A wear-resistant layer 2 formed by Ni-Cr-Mo-Fe-Nb-B-Si-C laser cladding.

[0033] Wherein, the weight ratio of the ceramic-metal composite material is: titanium-nickel alloy powder 10-20%; graphite carbon powder 1.5-3.5%; silicon powder 0.5-1%; nickel-chromium alloy powder 8-25%; Iron powder 5-10%; the balance is Cr 3 C 2 pink.

[0034] The two ends of the fins 3 are respectively welded between the surfaces of two adjacent water-cooled wall tubes 1 not provided with the wear-resistant layer 2, so that a plur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com